- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

>=99%

-

Voltage:

-

220/380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

2500*1600*2500MM

-

Weight:

-

700 KG, 650KG

-

Filling volume:

-

10-100ml

-

Capacity:

-

20-30bpm

-

Filling Precision:

-

≤±1%

-

Power Supply:

-

380V/50HZ

-

Capping Rate:

-

≥99%

-

Air Supply:

-

1.3 m3/h 0.4-0.8Mpa

-

Power:

-

2kw

-

Dimension:

-

1800*1000*1500mm

-

Keywords:

-

Oral liquid syrup filling machine

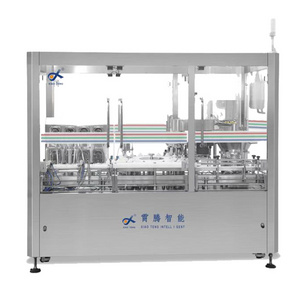

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Paper, Metal, Glass, Wood

-

Filling Material:

-

syrup, Oral liquid

-

Filling Accuracy:

-

>=99%

-

Voltage:

-

220/380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

2500*1600*2500MM

-

Weight:

-

700 KG, 650KG

-

Filling volume:

-

10-100ml

-

Capacity:

-

20-30bpm

-

Filling Precision:

-

≤±1%

-

Power Supply:

-

380V/50HZ

-

Capping Rate:

-

≥99%

-

Air Supply:

-

1.3 m3/h 0.4-0.8Mpa

-

Power:

-

2kw

-

Dimension:

-

1800*1000*1500mm

-

Keywords:

-

Oral liquid syrup filling machine

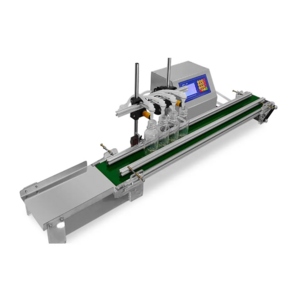

RELATED PRODUCTS

PRODUCT DESCRIPTION

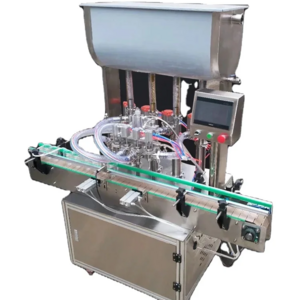

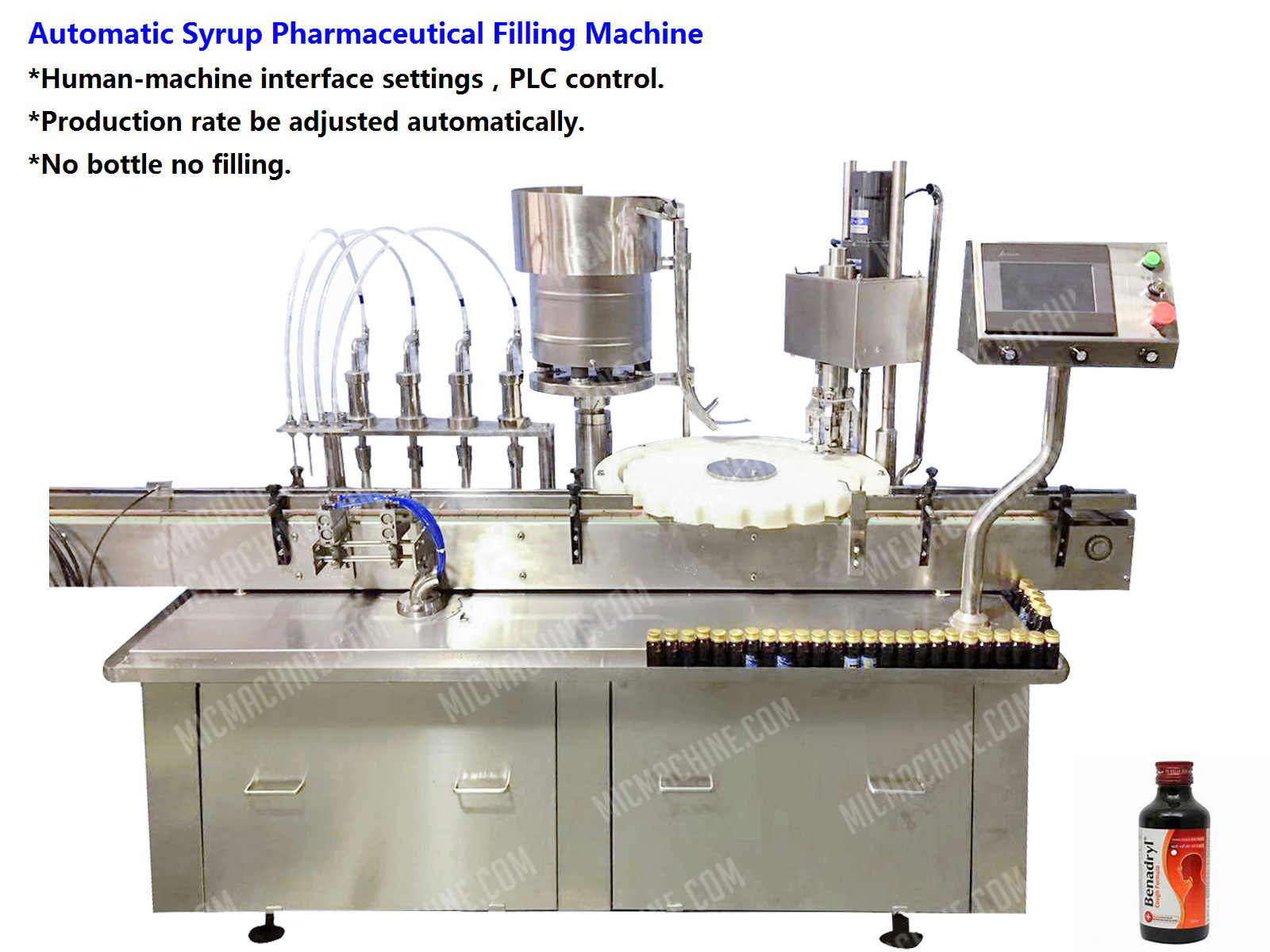

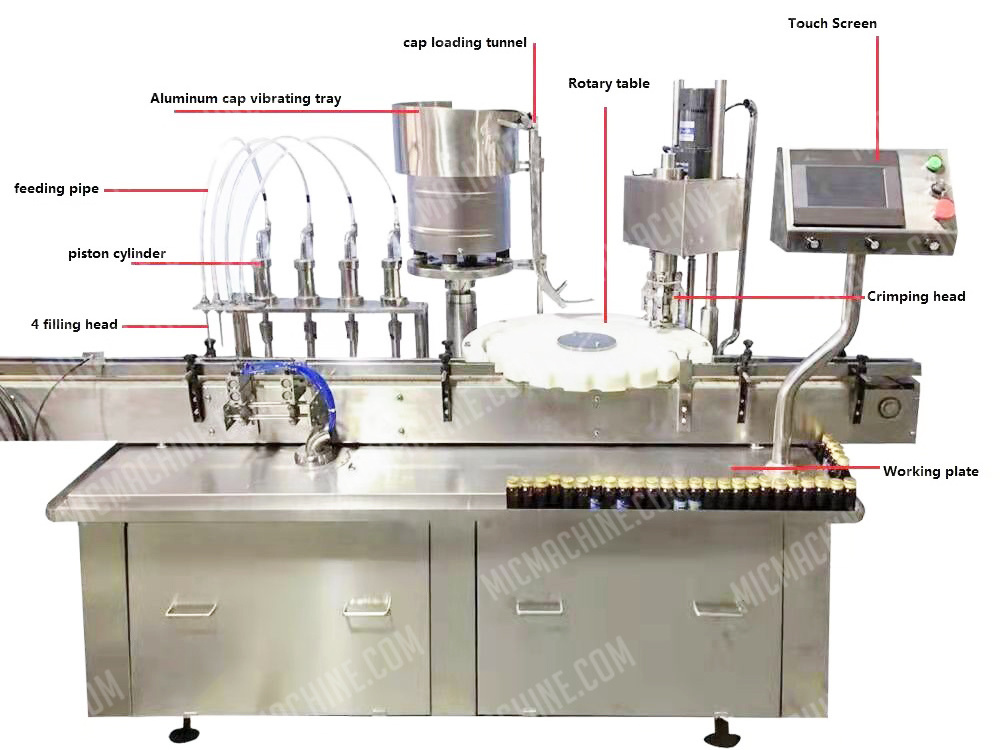

This machine is suitable for syrup and oral liquid filling and capping.

*Human-machine interface settings, an easy and intuitive, Plc control.

*Frequency control, the production rate be adjusted automatically count.

*No bottle no filling.

*High-precision cam meter control, precise positioning.

* 304 and 316 L stainless steel.

*Frequency control, the production rate be adjusted automatically count.

*No bottle no filling.

*High-precision cam meter control, precise positioning.

* 304 and 316 L stainless steel.

PRODUCT APPLICATION

PRODUCT PARAMETER

|

Model

|

MIC-XP40

|

|

Voltage

|

110V/220V/380V

|

|

Power

|

2kw

|

|

Air Pressure

|

0.6Mpa

|

|

Production Capacity

|

30-50BPM

|

|

Filling Volume

|

20-150ML

|

|

Filling Error

|

+/- 1%

|

|

Material

|

SS304/316

|

|

Dimensions

|

2000*1000*1500mm

|

|

Weight

|

600kg

|

DETAILED IMAGES

COMPANY INTRODUCTION

FAQ

Hot Searches