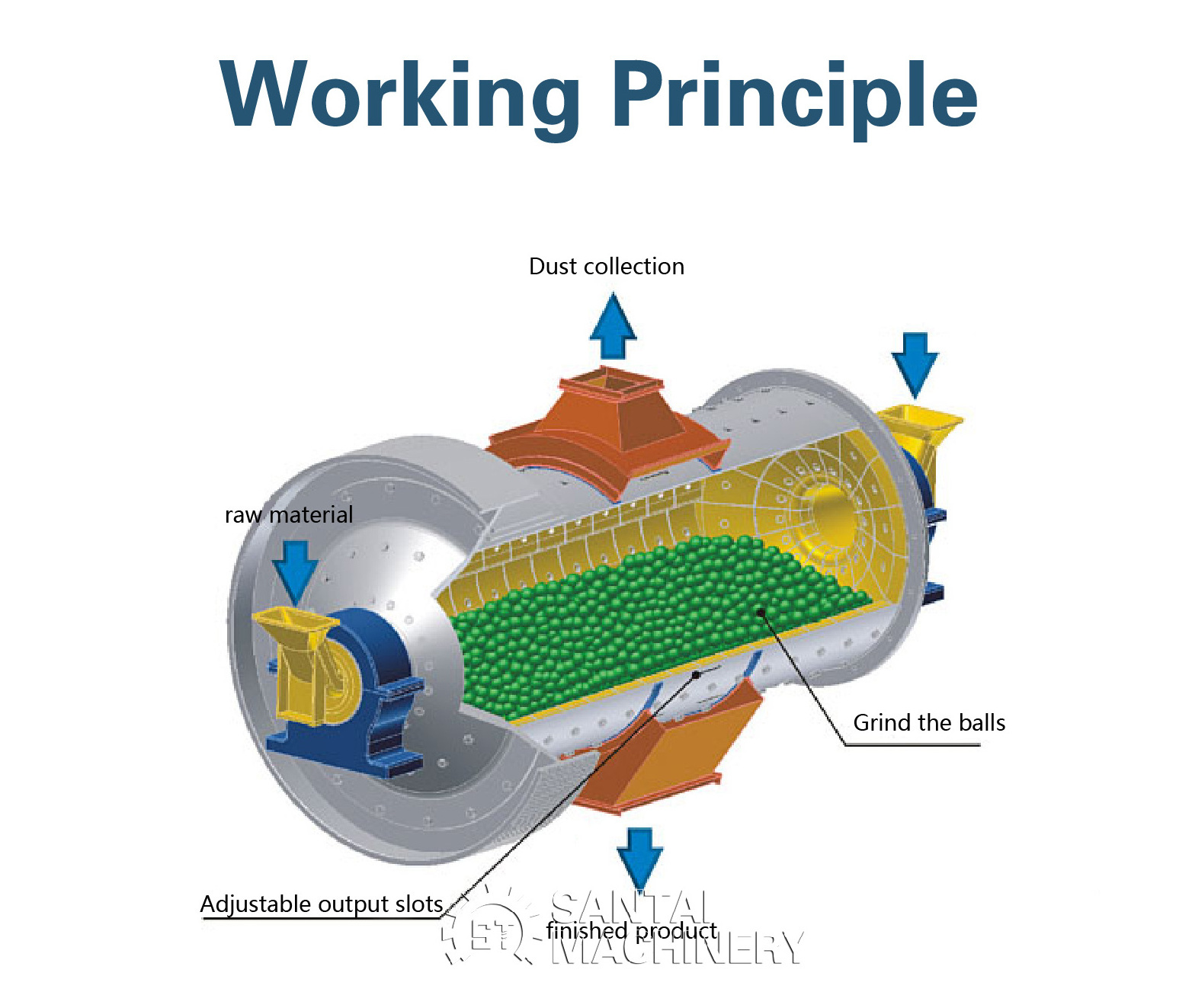

Dust collection raw material Grind the balls Adjustable output slots finished product

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

900*3000

-

Weight:

-

5600 KG

-

Application:

-

Stone Powder Grinding

-

Product name:

-

Ball Mill Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Name:

-

High Pressure Grinding Mill

-

Keywords:

-

Grinding Miller Ball Mill

-

The Machines classification:

-

Granding Mill Machine

-

Color:

-

Customer Requirement

-

Grinding media:

-

Steel Ball

-

Usage:

-

Grinding Mining Stone

-

Model:

-

Grinding Ball Mill Machine

Quick Details

-

Capacity(t/h):

-

1.1-3.5

-

Place of Origin:

-

Henan China

-

Brand Name:

-

Santai Machinery

-

Dimension(L*W*H):

-

900*3000

-

Weight:

-

5600 KG

-

Application:

-

Stone Powder Grinding

-

Product name:

-

Ball Mill Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Name:

-

High Pressure Grinding Mill

-

Keywords:

-

Grinding Miller Ball Mill

-

The Machines classification:

-

Granding Mill Machine

-

Color:

-

Customer Requirement

-

Grinding media:

-

Steel Ball

-

Usage:

-

Grinding Mining Stone

-

Model:

-

Grinding Ball Mill Machine

Products Description

Ball Mill

Ball mill is the key equipment for grinding crushed materials, which can be used for dry and wet grinding. Wear-resistant liner embedded in the cylinder body, with good wear-resistant performance. The machine runs smoothly, with reliable performance and high efficiency. In addition, it adopts full hydraulic operation, which is convenient to use and easy to automate, greatly improving the reliability and service life.

Product parameters

|

Model

|

Power

(kw)

|

Capacity

(t/h)

|

Rotating speed

(r/min)

|

Discharge size

(mm)

|

Weight

(t)

|

|

ST-900*1800

|

18.5

|

0.65-2

|

36-38

|

0.075-0.89

|

4.6

|

|

ST-900*3000

|

22

|

1.1-3.5

|

36

|

0.075-0.89

|

5.6

|

|

ST-1200*2400

|

30

|

1.5-4.8

|

36

|

0.075-0.6

|

12

|

|

ST-1200*3000

|

37

|

1.6-5

|

36

|

0.074-0.4

|

12.8

|

|

ST-1200*4500

|

55

|

1.6-5.8

|

32.4

|

0.074-0.4

|

13.8

|

|

ST-1500*3000

|

75

|

2-5

|

29.7

|

0.074-0.4

|

15.6

|

|

ST-1500*4500

|

90

|

3-6

|

27

|

0.074-0.4

|

21

|

|

ST-1500*4700

|

130

|

3.2-6

|

28

|

0.074-0.4

|

24.7

|

|

ST-1830*3000

|

130

|

4-10

|

25.4

|

0.074-0.4

|

28

|

The ball mill is filled with steel balls, which fall under the centrifugal force of the cylinder to grind the material. The use of a centripetal spherical double drum as support for the main shaft reduces energy consumption by 30% and increases output by 15%.

Details Images

Casting Large End Caps

Material, mould design, sand core, casting, shot blasting, heat treatment, machining, surface treatment

Rolling Bearings

Low friction, flexible start-up, bear radial and axial loads at the same time High rotary accuracy, good interchangeability

Inlet And Outlet Spirals

No clogging, no leakage, no air leakage, coarse ore, steel ball feeding back

Large Gears

High corrosion resistance, no rust, long service life, high tensile strength, various transmission ratios possible

Cylinder Body Part

High strength, sound manufacturing process, wear-resistant and fatigue-resistant with long service life

Corrugated Liner

Protect the cylinder, increase the friction, automatic grading ball, wear-resistant, anti-impact

Application Scenarios

Ball mills are used for crushing iron ore, copper ore, lead zinc ore, gold ore, steel slag, water slag, coal slag,

limestone,fluorite, barite, potassium feldspar, coal gangue, fly ash, white ash, desulfurization gypsum, cement clinker, cement,refractorymaterials, etc.

Hot Searches