- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Best Selling Product

-

Weight (KG):

-

8500 KG

-

Power (kW):

-

15

-

Product name:

-

Vacuum impregnadora wood impregnating machine impregnatation autoclave

-

Application:

-

Solid Wood

-

Raw material:

-

Q345R

-

Function:

-

Anticorrosive

-

Advantage:

-

Environment-friendly

-

Key words:

-

Impregnating machine

-

Voltage:

-

220v/380v/440v/Custom

-

Working Principle:

-

Vacuum Condition

-

Certification:

-

ISO

-

Working Pressure:

-

1.58 MPa

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhongnuo

-

Machine Type:

-

Wood anticorrosive machine

-

Marketing Type:

-

Best Selling Product

-

Weight (KG):

-

8500 KG

-

Power (kW):

-

15

-

Product name:

-

Vacuum impregnadora wood impregnating machine impregnatation autoclave

-

Application:

-

Solid Wood

-

Raw material:

-

Q345R

-

Function:

-

Anticorrosive

-

Advantage:

-

Environment-friendly

-

Key words:

-

Impregnating machine

-

Voltage:

-

220v/380v/440v/Custom

-

Working Principle:

-

Vacuum Condition

-

Certification:

-

ISO

-

Working Pressure:

-

1.58 MPa

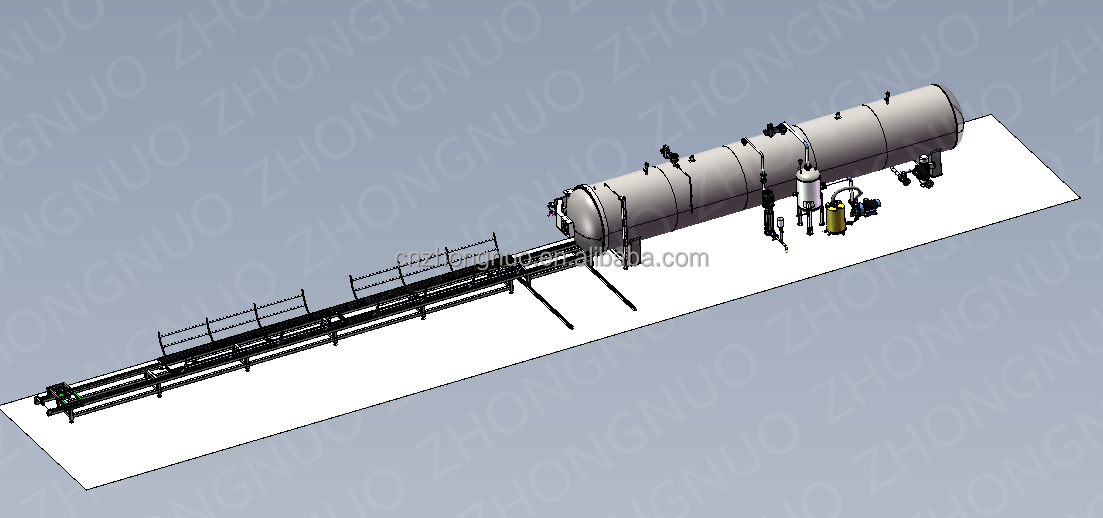

The process of using an autoclave for timber impregnation is fairly simple.

1.The first phase of the process is to use a vacuum to remove the air from the pieces of wood.

2.Next, non-harmful preservatives that are water-based or composed of other safe substances are then injected into the wood. This is what gives the wood the ability to last longer and resist the harm caused by bugs, rain, and other environmental elements.

3.The last phase of the process involves drying up the wood so it can be processed for shipping.

Application:

Professional automatic plant for pressure impregnated wood apply to wood’s corrosion protection, fire retardant, Termite control, fire prevention, insect-resistant, modification, dyeing, coking, degrease and deep processing. Wide applicability, better effect of processing, big capacity. reasonable layout, safety and reliable are the advantages of this equipment. And it also have advantages of reduce labor intensity and working cost. It completely meet the requirement of deep processing of all kinds of wood.

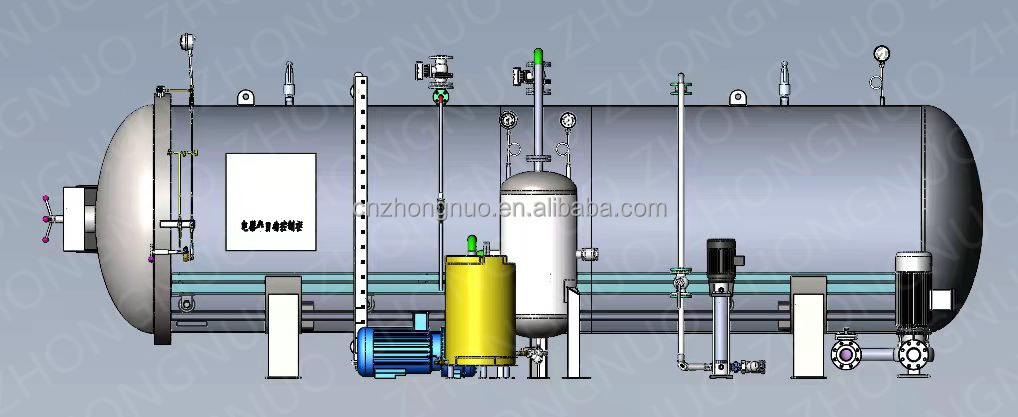

Product Paramenters

|

Autoclave Inter Diameter/Length/Volume

|

1000mm /12500mm/9.8m3

|

|

Max Working Pressure

|

1.0-1.4Mpa

|

|

Test Pressure

|

1.58Mpa

|

|

Working Temp.

|

Room Temp.

|

|

Vacuum Pressure

|

0~ -0.098 Mpa

|

|

Medium

|

Water-soluble preservative, flame retardant, modifier

|

|

Power

|

Pressure Booster Pump 7.5KW;

Vacuum Pump 11KW;

Discharge pump 5.5KW

|

|

Electric Voltage

|

3 phases electric power

|

|

Material

|

Q345R

|

|

Autoclave thickness

|

10mm

|

|

The way of open the door

|

Open by hand

|

|

Sealing Way

|

Inflatable silicone seal

|

|

Control Way

|

Electric automatic control

|

|

Safety Way

|

Tank door double safety interlock, tank double safety interlock

|

|

Alarm Way

|

Ultra high voltage automatic power failure alarm

|

Products Description

Preparation:

1. 3 Phases Electric Power

2. Air Compressor(1m3/min)

3. Chemical Liquid Tank(1.5 times of autoclave volume)

4. Add water into water tank

5. Set Negative Gauge(Lower than -0.098Mpa)

6. Set Pressure Gauge(1.2-1.3Mpa)

7. Set Pressure Time

2. Air Compressor(1m3/min)

3. Chemical Liquid Tank(1.5 times of autoclave volume)

4. Add water into water tank

5. Set Negative Gauge(Lower than -0.098Mpa)

6. Set Pressure Gauge(1.2-1.3Mpa)

7. Set Pressure Time

Vacuum Pump.

Make Autoclave to Negative Pressure -0.098Mpa Situation. Discharge cooling air out of autoclave

Vacuum Buffer Tank

Set and check the negative pressure value

Discharge Pump

Discharge chemical liquid after finish the impregnation.

Distribution Box

All switches controlling.

Power ON/OFF,Vacuum, Time, Pressure Booster, Discharge and air return.

Air Pipes

Connect air compressor, door sealing.

Steel Pipes Markers

Add markers to install pipes easily

Operation:

Operation:

2. Open the door, put timber into autoclave.

3. Open ‘Door Sealing OFF’ ,Close ‘Door Sealing ON’.

4. Open ‘Power Switch’

5. Open ‘Vacuum Switch’, the autoclave will running to negative pressure to -0.098Mpa. And then Vacuum pump will stop running.Close ‘Vacuum Switch’.

6. Set Pressure Booster Time, Set Positive Pressure Value according to customers requirements.

7. Open ’Liquid Inlet Valve’by handle, Close ‘Discharge Valve’ by handle .Chemical Liquid flows into autoclave.

8. Open ‘Pressure Booster Valve ’ by Handle.

9. Watch ‘Liquid Level Gauge’, when it reach the level what you need, . close the ‘Liquid Inlet Valve’

10. Open ’Pressure Switch’. The autoclave raise pressure to 1.2-1.3Mpa.It will be stop running after reach time what you set. And Alarm Buzzing. But autoclave still keep high pressure. Close ’Pressure Switch’. Close‘Pressure Booster Valve ’ by Handle.

11. Open ‘Discharge Valve’by handle. Watch the ‘Liquid Level Gauge’,when it reach to zero. Close it.

12. Open the ‘Air inlet valve’ and then open the ‘air inlet switch’.watch the ‘pressure gauge’ value to zero.and close valve and switch.

13. Close ‘Door Sealing Off’,Open ‘Door Sealing ON’

14. Open the door, take timber out.

2. Open the door, put timber into autoclave.

3. Open ‘Door Sealing OFF’ ,Close ‘Door Sealing ON’.

4. Open ‘Power Switch’

5. Open ‘Vacuum Switch’, the autoclave will running to negative pressure to -0.098Mpa. And then Vacuum pump will stop running.Close ‘Vacuum Switch’.

6. Set Pressure Booster Time, Set Positive Pressure Value according to customers requirements.

7. Open ’Liquid Inlet Valve’by handle, Close ‘Discharge Valve’ by handle .Chemical Liquid flows into autoclave.

8. Open ‘Pressure Booster Valve ’ by Handle.

9. Watch ‘Liquid Level Gauge’, when it reach the level what you need, . close the ‘Liquid Inlet Valve’

10. Open ’Pressure Switch’. The autoclave raise pressure to 1.2-1.3Mpa.It will be stop running after reach time what you set. And Alarm Buzzing. But autoclave still keep high pressure. Close ’Pressure Switch’. Close‘Pressure Booster Valve ’ by Handle.

11. Open ‘Discharge Valve’by handle. Watch the ‘Liquid Level Gauge’,when it reach to zero. Close it.

12. Open the ‘Air inlet valve’ and then open the ‘air inlet switch’.watch the ‘pressure gauge’ value to zero.and close valve and switch.

13. Close ‘Door Sealing Off’,Open ‘Door Sealing ON’

14. Open the door, take timber out.

Negative Pressure Gauge

Positive Pressure Gauge

Pneumatic Valve

Door Sealing

Safety Valve

Electric Wires Protection

1.Q345R steel which have good comprehensive mechanical property and processing property is a kind of pressure vessel special material.

2.Automatic submerged arc welding,it has advantages of high productivity,good weld quality and low labor intensity. And it also hasn't arc radiation.

3.With the gas-filled silica gel seal ring,the sealing effect of the equipment is significantly better than others'. And the life of the equipment is more than one year

4 Automatic pressure safety interlocking method and and Manual safety interlocking method,it solved the safety problem of wrong operation.

5.Using vacuum pressure impregnation method,the resistance will reduce when the wood preservative pushed into wood,so the wood preservative will be easy to get into wood.

6.During whole process,it control pressure automatically,such as,you can set pressure 1.4MPA,once it get it,the pump will be off work once lower than 1.0Mpa,it will start.

Recommend Products

Hot Searches