- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

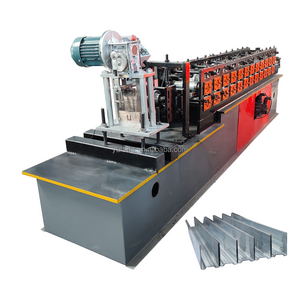

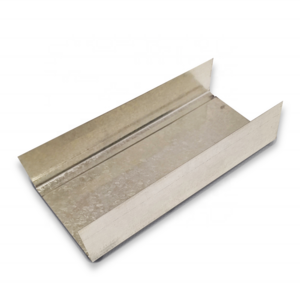

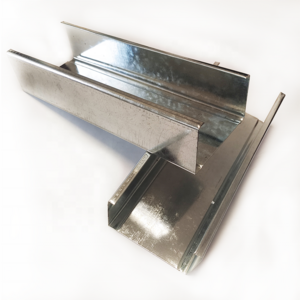

Stud Channel Roll Forming Machine

-

Raw material:

-

Galvanized Sheet

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Thickness:

-

0.3-1mm

-

Motor brand:

-

Delta

-

Application:

-

Building Construction

-

Main frame:

-

300H Steel

-

After-sales Service Provided:

-

Online support, Free spare parts, Video technical support

-

Certification:

-

ISO,CE

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

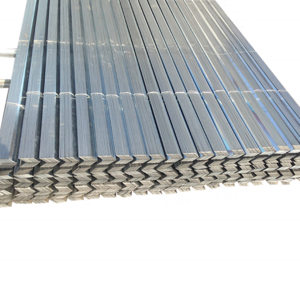

8-12m/min

-

Product name:

-

Stud Channel Roll Forming Machine

-

Raw material:

-

Galvanized Sheet

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Thickness:

-

0.3-1mm

-

Motor brand:

-

Delta

-

Application:

-

Building Construction

-

Main frame:

-

300H Steel

-

After-sales Service Provided:

-

Online support, Free spare parts, Video technical support

-

Certification:

-

ISO,CE

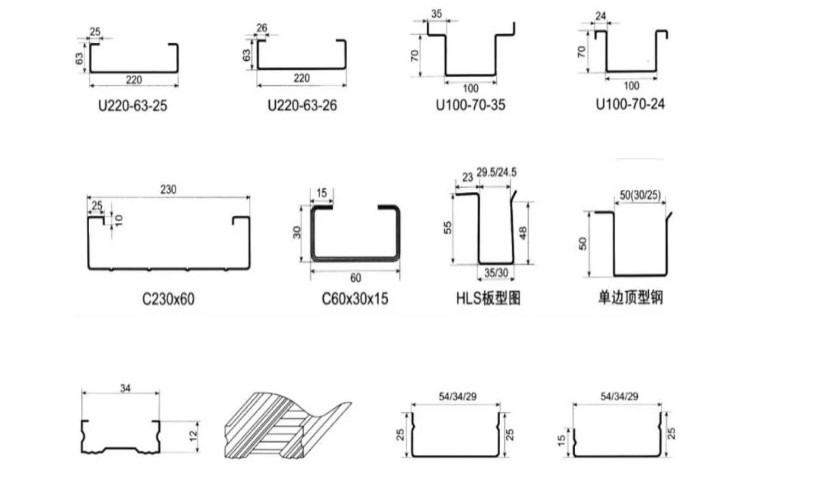

Trade Assurance U Keel Galvanized Drywall Used Building scaffold making machine

- 1.Professional Technical Team

- The company has professional teams which are respectively responsible for product development, mechanical assembly and precision parts processing.

- 2.Leading Technology

- We adopt Italian advanced automation control concept so as to reduce the human power .

- 3.Strict Control

- Our products follow the principle of production self-inspection, storage inspection and dispatch inspection.

- Our equipment has a warranty of one year and we only charge the repair cost outside one year. our equipment has been standardized and modularized.

- Whether which place you are in, as long as connecting to the Internet, you can get online fault diagnosis and repair.

Technical parameter

|

Metal stud roll forming machine |

||

|

1 |

Operating Voltage |

380V,50Hz,3 phases or customized |

|

2 |

power |

4kw |

|

3 |

productivity |

25m/min |

|

4 |

Material type |

Strip steel |

|

5 |

Roller station |

12 forming steps+4 leveling steps |

|

6 |

Thickness to process |

0.3~1.5mm |

|

7 |

Main Frame |

300H-beam steel |

|

8 |

Roller material |

Gcr15 steel,quenched |

|

9 |

Side-wall thickness |

20mm |

|

10 |

Bearing brand |

Harbin |

|

11 |

Chain |

1.1 inches |

|

12 |

Frequency converter |

Equipped |

Product

Control box: be packed with thick cardboard, and outer side thick waterproof plastic film

All parts inside container will be fixed very well which can keep safety and fixed for long time sea transportation