- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Supereal

-

Name:

-

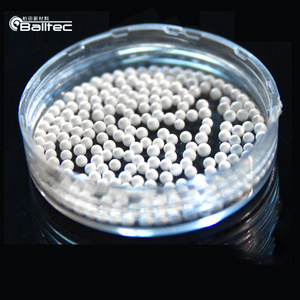

alumina ceramic beads

-

Alumina content:

-

≥ 95%

-

Shape:

-

beads

-

Self Wear Rate:

-

<0.01% (24h)

-

Size:

-

0.5mm-20mm

-

Bulk Density:

-

≥3.65

-

Water Absorption:

-

<0.01%

-

Hardness:

-

9 Moh's

-

(1:9H C1) Acid resistance:

-

6.545 mg/cm 2

-

(10% NaOH) Alkali resistance:

-

0.143 mg/cm 2

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Customer's Requirements

-

Brand Name:

-

Supereal

-

Name:

-

alumina ceramic beads

-

Alumina content:

-

≥ 95%

-

Shape:

-

beads

-

Self Wear Rate:

-

<0.01% (24h)

-

Size:

-

0.5mm-20mm

-

Bulk Density:

-

≥3.65

-

Water Absorption:

-

<0.01%

-

Hardness:

-

9 Moh's

-

(1:9H C1) Acid resistance:

-

6.545 mg/cm 2

-

(10% NaOH) Alkali resistance:

-

0.143 mg/cm 2

High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill

1. Brief Introduction:

With overwhelming merits in higher density, more regular shape, easily classifying and assorting, superior grinding efficiency and competitive price prior to natural cobble stones and conventional grinding media, High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill are excellent for grinding processing of many industries.

High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill has the following properties:

♦ High hardness second only to Diamond

♦ Lower wear lost

♦ Good normalization

♦ Good corrosion resistance

♦ Higher grinding efficiency

♦ Contamination-free

♦ Longer service life

2. Production Process of High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill:

3. Technical data:

Technical Index of High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill

High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill :

Alumina ceramic grinding cylinder:

Note: As the High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill , at a comparable weight with grinding balls, alumina ceramic cylinders have an approx.14% greater surface than alumina ceramic grinding ball.

4. Packing and shipping for High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill

5. Application

High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill are mainly used in ceramic, glaze, paint, zirconia silicate, aluminum oxide, quartz, silicon carbide, talc, building material, chemical, inks, kaolin, cosmetics,cement,and other materials grinding.

Remarks:

Grinding ways of High Alumina Grinding Media Alumina Sphere as Grinding Media for Ball Mill involve two types: Wet grinding and Dry grinding

Wet Grinding Instruction (Ceramic industry)

For wet grinding process,when charge of ball is up to 55% of net volume of the mill,the best status can be realized.

The volume of ball within the mill can be estimated with formula:

W=3.14×R×D×L×25%/1000

Notes:

W—weight of ball(Kg)

R—radius of mill(cm)

D—bulk density of ball(g/cm3)

L—length of mill(cm)

For glaze grinding —raw material: ball=1:(1.8 ~ 2.0)

Special Note:Ball-Washing

While grinding glaze , in the case of charging the whole Ball Mill with new alumina balls,you are strongly recommended to complete the procedure namend Ball-Washing.It means you should let the whole batch of new alumina balls grinding themselves with water for more than 2 hours, then drain the water and the impurity from the Ball Mill.This is the preparative process recommended before grinding glaze by new balls.

For body material grinding —raw material: ball=1:(1.0 ~ 1.2)

Dry Grinding Instruction

The volume of raw materials=Effect capacity of mill×35%

The volume of ball=Effect capacity of mill×50%