- Product Details

- {{item.text}}

Quick Details

-

Working temperature:

-

-50~200℃

-

Certification:

-

UL,RoHS,Reach,ISO9001,IATF16949

-

Color:

-

White/black/translucent

-

Sample:

-

Free Samples(No mail)

-

Features:

-

Good adhesive, good leveling, seismic, good fire resistance

-

Thermal conductivity:

-

0.5~3.0W/m.k or customize

-

surface dry time:

-

≤30min

-

elongarion ar break:

-

≥80%

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KUAYUE

-

Model Number:

-

HCJ

-

Working temperature:

-

-50~200℃

-

Certification:

-

UL,RoHS,Reach,ISO9001,IATF16949

-

Color:

-

White/black/translucent

-

Sample:

-

Free Samples(No mail)

-

Features:

-

Good adhesive, good leveling, seismic, good fire resistance

-

Thermal conductivity:

-

0.5~3.0W/m.k or customize

-

surface dry time:

-

≤30min

-

elongarion ar break:

-

≥80%

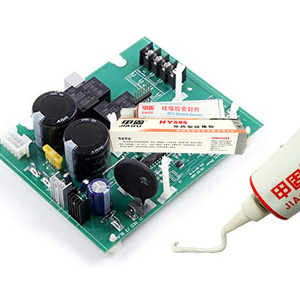

Organic electronic potting compound silicone for quakeproof, seal, electronic components

The HCJ series is a single-component room temperature curing organosilicon adhesive. It is a kind of heat conduction through the condensation of water in the air that releases low molecules to cause cross-linking curing, which is vulcanized into high-performance elastomers and can be beneficial to heat sources. radiator, motherboard and shell.

HCJ Adhesive Silica Gel data

| Characteristics | HCJ100 | HCJ150 | HCJ200 | HCJ300 | Unit | Test Method |

| Appearance | White half flowing | White half flowing | White half flowing | White half flowing | visuai | |

| Density | 1.7 | 1.9 | 2.3 | 2.8 | g/cm3 | ASTM D792 |

| Table dry time | 5 | 5 | 5 | 5 | min | stopwatch |

| Hardness | 50 | 50 | 50 | 50 | shore A | ASTM D2240 |

| Tensile strength | 0.1 | 0.1 | 0.1 | 0.1 | Mpa | ASTM D412 |

| Extension rate | 100~150 | 100~150 | 100~150 | 100~150 | % | ASTM D374 |

| Temperature resistance range | -60~200 | -60~200 | -60~200 | -60~200 | ℃ | EN344 |

| Volume resistivity | 2.0×10 14 | 2.0×10 14 | 2.0×10 14 | 2.0×10 14 | Ω.cm | ASTM D257 |

| Dielectric constant | 2.8 | 2.8 | 2.8 | 2.8 | 1.2MHz | ASTM D150 |

| Thermal conductivity coefficient | 1.0 | 1.5 | 2.0 | 3.0 | W/m.k | ASTM D5470 |

1. Excellent thermal conductivity

2. Good adhesion performance

3. Good insulation performance

4. Solvent resistance, Corona resistance

5. Water-proof, water-proof performance

6. Seismic, UV resistance

1. Can replace the traditional spring or screw fixed installation method, the process is simple and more economical

2. Heat conduction and bonding between high-power power power module and radiator

3. Thermal conductivity and adhesion between LED lamp aluminum substrate and radiator

4. High speed buffer memory, integrated circuits, other electronic equipment

Q1. Can we get some free samples from you?

A: Yes, you can get some free samples, but the shipping cost of samples should be paid by you.

Q2. what's certificates of thermal conductive materials you have? and how to make sure your products' quality meet with the requirement of UL?

A:We have obtain UL, SGS, ROHS ISO and REACH certificattes, approved by third party with testing report. we can provide you with the testing report of thermal conductive matrials to ensure our product quality.

Q3. Is thermal conductive gap filer pad can customize and die-cut?

Q4. What's the benefits for electronic products to assemble thermal conductive silicone pad?

Q5. Do theermal conductive materials of your company have natural inherent stickiness on the surface?

Q6. What does the thermal conductive pad's natural inherent stickiness refer to?

Q7. What's the series of your thermal conductive materials?

A: We have thermal conductive silicone pad with different thermal conductivity including HC100, HC150, HC200, HC250,HC300,HC400,HC500, HCP100. And we have thermal conductive adhesive tape: HCT with PET as base material and HCTM without PET as base material. We also have thermal conductive graphite sheet apply in different electronic industries. GSH is apply on smart phone, GSB is for laptop , and GSM is for LED.

Q8. Is thermal conductive gap filler pad with fiberglass?

A: Yes , all the thermal conductive materials except HCP series, thickness no more than 0.5mm can add fiberglass as carrier.

Q9. What kind of industry do your products mainly apply in?

A: Our products are widely used in various industries, including poower supply, LED lights, laptop, LED TV, Set top box, communication, heat transfer, chip IC, automotive electronics and photoelectricity etc.

Q10. What is life expectancy of thermal conductive silicone pad?

A: Our thermal conductive silicone pad use silicone rubber as based material. The service life of silicone pad depend on the service life of silicone rubber. The silicone rubber industry recognizes a 20-year life for silicone rubber when used within specified operation parameters.

Q11. What is the shelf life of thermal conductive gap filler pad?

A: The shelf life is a measurement of stable storage life in specified storage conditions. Shelf life for thermal conductive gap filler pad is one year after date of manufacture. For thermal conductive gap pad with adhesive, the shelf life is six months after the date of manufacture. After these dates, inherent tack and adhesive properties should be re-characterized.

Q12. Are thermal conductive materials eletrically isolating? Would they cause the short circuit of electronic components?

A: Yes, all our thermal conductive materials are isolating with the voltage endurance over thousands of volt.