- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

LZ

-

Model Number:

-

TRD-70

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

3HP

-

Cable Length:

-

none

-

Outlet Size:

-

none

-

Power:

-

none

-

Theory:

-

Vacuum Pump

-

Standard or Nonstandard:

-

Standard

-

Product name:

-

High Vacuum Industrial Rotary Vane Oil Vacuum Pump Series

-

Vacuum degree:

-

High vacuum degree

-

Noise:

-

Low noise

-

Service life:

-

Long service life

-

Working temperature:

-

Low working temperature

Quick Details

-

Application:

-

Food and Beverage Industry, Industrial Utilities, Machining, Mining industry, Pharmaceutical industry, Washing and Cleaning

-

Pressure:

-

0.5Pa, Low Pressure

-

Voltage:

-

CUSTOM, 380V

-

Warranty:

-

1 year

-

Brand Name:

-

LZ

-

Model Number:

-

TRD-70

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

3HP

-

Cable Length:

-

none

-

Outlet Size:

-

none

-

Power:

-

none

-

Theory:

-

Vacuum Pump

-

Standard or Nonstandard:

-

Standard

-

Product name:

-

High Vacuum Industrial Rotary Vane Oil Vacuum Pump Series

-

Vacuum degree:

-

High vacuum degree

-

Noise:

-

Low noise

-

Service life:

-

Long service life

-

Working temperature:

-

Low working temperature

High vacuum industrial double stage rotary vane vcuum pump

TRD series double stage vacuum pump:

Product Description:

1.Excellent ultimate vacuum.

2.After downtime, air inlet automatic sealing, can maintain the vacuum container in the vacuum state

3.Constant pressure oil circulating system, keep working state oil circulation.

4.Convenient gas ballast valve control.

5.Convenient oil level checking and changing.

| Model | TRD-40 | TRD-60 | TRD-70 | TRD-100 | Unit | |

| Item | ||||||

| Pumping speed | 50Hz | 40 | 60 | 70 | 100 | m^3/h |

| 60Hz | 48 | 72 | 84 | 120 | ||

| Ultimate vacuum | Gas Ballast Off | 5x10^-1 | Pa | |||

| Gas Ballast On | 2.0 | |||||

|

Three-phase motor power |

1.1(4P) | 1.2(6P) | 1.5(4P) | 2.2(4P) | KW | |

| Speed | 50Hz | 1440 | 960 | 1440 | 1440 | r/min |

| Oil capacity | Min | 1.8 | 3 | 3.5 | 4.5 | L |

| Max | 2.5 | 4 | 5 | 6 | ||

| Inlet diameter | KF40 | DN | ||||

| Exhaust diameter | KF40 | DN | ||||

| Weight | 44 | 64 | 65 | 84 |

Kg

|

|

N ote: the " Ultimate vacuum " in the table is the measured value of Pirani vacuum gauge, if use McLeod vacuum gauge, the measured value is about 5×10-2Pa.

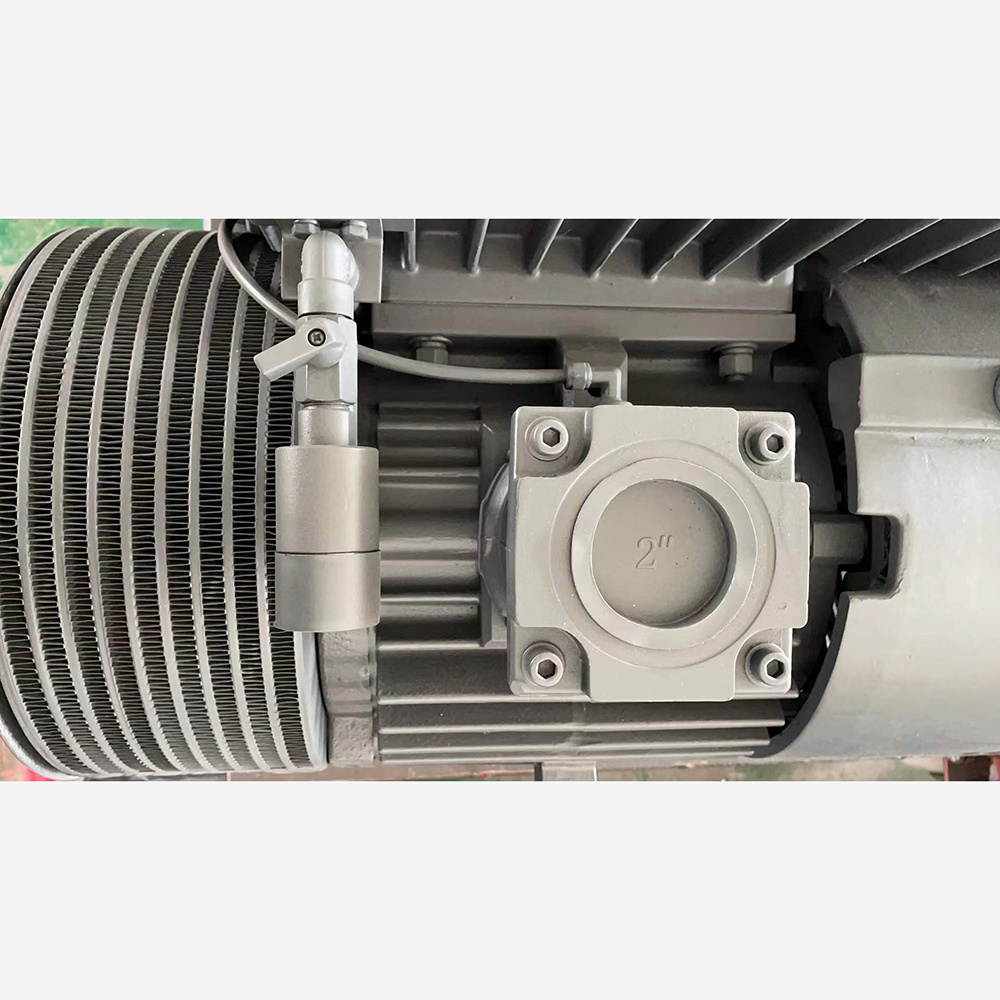

Pump picture:

Installation dimensions:

Scope of application:

1:Car industry

2:Food industry

3:Furnaces and plants

4:Laser technology

5:Medicinal technology

6:Metallurgy

7:Power engineering, long-distance energy

8:Space simulation

9:Vacuum coating

Vacuum packaging, drying, distillation, concentration, loading and unloading, and attract, vacuum forming, etc

Operation:

1.The pump should be placed on the flat position horizontally. The pump has screw holes used for fixing the pump at the

bottom cushion block.

2.Please check the oil level before starting the pump. Fill oil to the oil window 3/4 position.

3.Electrical wiring should be carried out by a professional electrician, Vacuum pump standard 380v50hz three phase motor,

please look at the motor nameplate.After completion of three phase asynchronous motor wiring must rotate to check the motor,

running in the direction shown by the arrow .

4.Inlet pipe cross section size should not be less than the suction mouth size and link length as short as possible.Otherwise it will

affect the efficiency.

5.If the pumped gas have impurities,steam or foreign matter,you need to install a vacuum filter on pump air inlet. You also can join an

exhaust pipe if necessary, the exhaust pipe need to slope down.

6.The oil level must be check after startup,please insure the oil level in the oil window 3/4 place. When the pump is operating at high

temperature, do not touch!

Internal structure:

Maintenance:

Factory configuration oil - CV - AH200 high vacuum oil, must use the ISO VG 100 viscosity grade of vacuum pump oil,

vacuum pump operation must ensure that the oil level in the oil window height of 1/2 3/4, regularly check the oil level and oil pollution, oil change.

Packaging & Shipping

Packaging:

Standard export wooden cases packing

Shipment:

Sea transport /Air transport ( DHL ,TNT , Fedex... )

Delivery time:

25 working days for 20 GP, 35 days for 40HQ