During the production, another coil materials can be loaded on the other uncoiler head without stop the machine.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V, 380V/50HZ/3PH

-

Dimension(L*W*H):

-

200*300*200

-

Weight:

-

18500 kg

-

Machine Name:

-

solar photovoltaic support bracket making machinery

-

Usage:

-

PV border frame

-

Roll Forming stands:

-

22 Rollers station

-

Roller material::

-

Cr12Mov

-

Control system:

-

Delta

-

Motor brand:

-

Mistubishi

-

Color:

-

Customer's Requirement

-

Certification:

-

CE Certificate

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

Other

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V, 380V/50HZ/3PH

-

Dimension(L*W*H):

-

200*300*200

-

Weight:

-

18500 kg

-

Machine Name:

-

solar photovoltaic support bracket making machinery

-

Usage:

-

PV border frame

-

Roll Forming stands:

-

22 Rollers station

-

Roller material::

-

Cr12Mov

-

Control system:

-

Delta

-

Motor brand:

-

Mistubishi

-

Color:

-

Customer's Requirement

-

Certification:

-

CE Certificate

Products Description

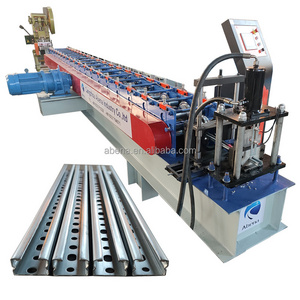

KINGREAL Unistrut Channel Roll Forming Machine

This equipment can meet the production requirements of different specifications of bracket by manually adjusting or changing several groups of rollers. Solar photovoltaic bracket is designed for placing, installing and fixing solar panels in the solar photovoltaic power generation system.

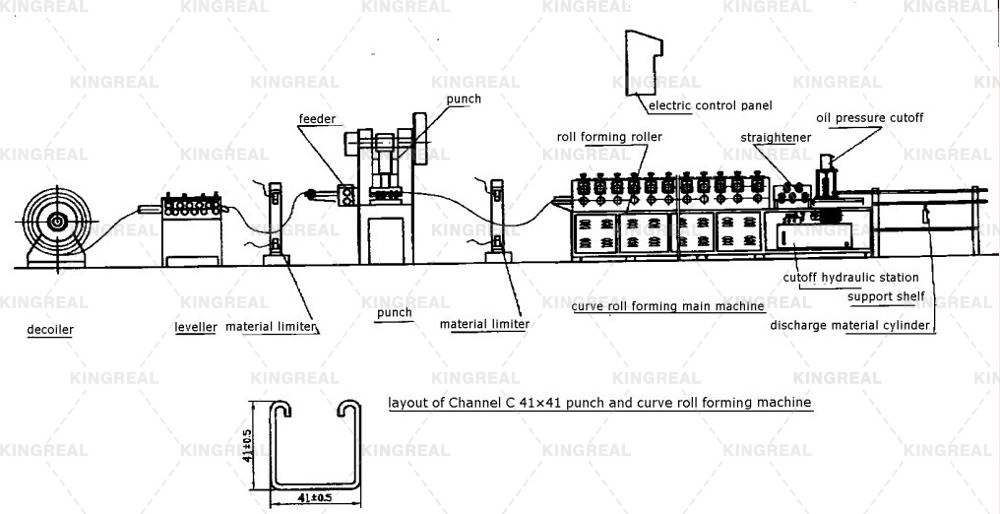

The production process of automatic solar photovoltaic bracket molding machine is as follows:

Uncoiling -- feeding guide platform -- leveling and straightening -- servo feeding -- online punching -- roller forming (including gear hobbing and shaping) -- cutting -- receiving, including hydraulic control system, electrical control box control system and other parts.

It has the characteristics of reasonable structure, simple operation, reliable, short production process and wide use

Uncoiling -- feeding guide platform -- leveling and straightening -- servo feeding -- online punching -- roller forming (including gear hobbing and shaping) -- cutting -- receiving, including hydraulic control system, electrical control box control system and other parts.

It has the characteristics of reasonable structure, simple operation, reliable, short production process and wide use

Double heads decoiler is for the high speed profile roll forming continuously.

We can design a variety of profiles to be produced by one machine in accordance with client’s requirements, and to save space.

Also by using programs we simultaneously control the sequential production of different lengths

of multiple profiles to provide clients with flexible production solutions.

of multiple profiles to provide clients with flexible production solutions.

Unique Rotate Fly Punch & Shearing System

steel keels.

The system uses a high-power servo feeder to drive the axle to work continuously without stopping, which can improve running speed of the entire line and output efficiency.

PROFESSIONAL DESIGN & TRAINING SUPPORT

Our company has established a long-term friendly relationship with the famous Dutch roller design company "HDE".Relying on the powerful design capabilities and technical support of HDE, our company can carry out rolling processing of various complex profile products.

And to a certain extent, our overall processing technology level has been improved.

HIGH QUALITY ELECTRICAL APPLIANCES

We use high-quality imported electrical appliances, such as Japanese Yaskawa NC servo feeder, PLC from FATEK, MCGS touch screens, which can ensure stable and continuous work of our machines.

Certifications

Our products have passed the international ISO9001 and European CE certification,

and being exported to many European countries.

Related products

Hot Searches