- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JOYE

-

Dimension(L*W*H):

-

1140*1500*1560mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Model Number:

-

MR8-200R

-

Machine type:

-

Automatic Rotary Bag Given Packing Machine

-

Machine material:

-

SS304/SS316

-

Payment item:

-

TT 30%,70% before shipping

-

Factory/CNC:

-

YES

-

Keyword:

-

stand up pouch

-

Product name:

-

automatic packing machine

-

Bag type:

-

seal bags,block bottom bags,zipper bags,stand-up pouch

-

Certification:

-

CE/ISO9001

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing, weighing

-

Packaging Type:

-

Stand-up Pouch, Bags, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JOYE

-

Dimension(L*W*H):

-

1140*1500*1560mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Model Number:

-

MR8-200R

-

Machine type:

-

Automatic Rotary Bag Given Packing Machine

-

Machine material:

-

SS304/SS316

-

Payment item:

-

TT 30%,70% before shipping

-

Factory/CNC:

-

YES

-

Keyword:

-

stand up pouch

-

Product name:

-

automatic packing machine

-

Bag type:

-

seal bags,block bottom bags,zipper bags,stand-up pouch

-

Certification:

-

CE/ISO9001

Click HERE to Contact Us for the Free Packaging Solution and Discount!

Or Click "Chat Now" at the Bottom of your App.

PACKING SOLUTION

The Filling System is Just for Your Reference.We Will Offer You the Best Solution According to Your Product Mobility, Viscosity, Density, Volume, Dimensions, Etc.

-

- Powder Packing Solution —— Servo Screw Auger Filler Is Specialized for Power Filling Such as Nutrients Power, Seasoning Powder, Flour, Medicinal Powder, Etc.

- Liquid Packing Solution —— Piston Pump Filller Is Specialized for Liquid Filling Such as Water, Juice, Laundry Detergent, Ketchup, Etc.

- Solid Packing Solution —— Combination Multi-head Weigher Is Specialized for Solid Filling Such as Candy, Nuts, Pasta, Dried Fruit, Vegetable, Etc.

-

Granule Pack Solution

—— Volumetric Cup Fillier Is Specialized for Granule Filling Such as Chemial, Beans, Salt, Seasoning, Etc.

——————

APPLOCATION

——————

APPLCABLE BAG TYPE

-

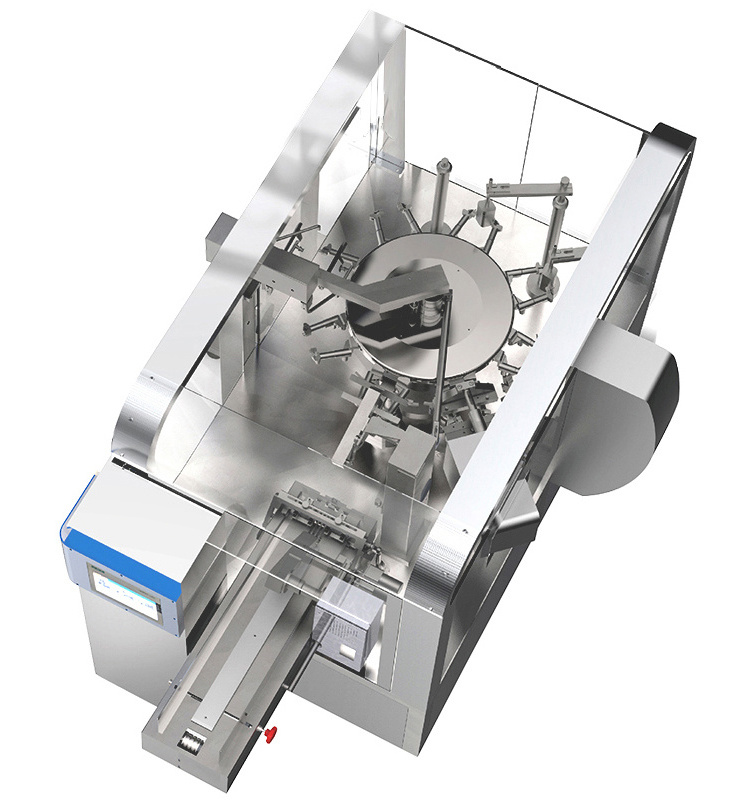

| The Main Technical Parameters | |

| Model | MR8-200/300RW |

| Bag Size | Width:80-210/200-300mm, Length:100-300/100-350mm |

| Filling Volume | 5-2500g (Depending on type of products) |

| Capacity |

30-60bags/min (The speed depends on type of products and packaging material used)

25-45bags/min (For zipper bag) |

| Package Accuracy |

Error≤±1% |

| Total Power | 2.5KW (220V/380V,3PH,50HZ) |

| Demension | 1710*1505*1640 (L*W*H) |

| Weight | 1480KGS |

| Compress Air Requirement | ≥0.8m³/min supply by user |

|

We can customize the suitable one for you according to your requiredment. Just Tell us : Weight or Bag Size required. |

|

| Parts of Machine | ||||||||||

| Parts | PLC | Touch Screen | Frequency Conveter | Vacuum Pump | Printer | Main Motor | Temperature Controllor | Proximoty Swith |

Magnetic Value |

Cylinder |

| Brand | SIEMENS | SIEMENS | TOSHIBA | ORION | SHENG LONG | EVERGEAR | AISET | OMRON | FESTO | AIRTAC |

| Oringin | Germany | Germany | Japan | Japan | China | China | China | Japan | Germany | China |

| Can replace parts as needed | ||||||||||

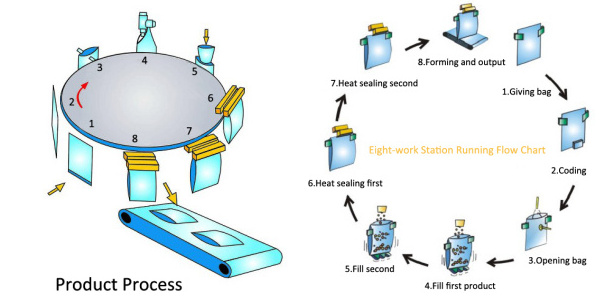

| Work Process | |

| Safety Measures |

1.no bag feeding, no filling and no sealing. 2.no bag opening/open error, no filling and no sealing 3.no filling, no sealing |

|

Product Process |

Station 1 Bag Feeding

Station 2 Date Printing (option)and Open zipper bag Station 3 Open bag Station 4 Filling Materials Station 5,6,7 : Vibration,Air Removal,Nitrogen Filling,Close Zipper,Hole Punching,Heat Sealing Remark:No.5.6.7.Stations are based on customer requirements for adjusting. Station 8 Heat Sealing and Product Output |

|

Stations are based on customer requirements for adjusting. |

|

Click HERE to Contact Us for the Free Packaging Solution and Discount!