- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

as actual situation

-

Power:

-

55 kw

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

188 kg

-

Keyword:

-

cement kiln

-

Application:

-

Cement Clinker

-

Fuel:

-

Coal,Nature Gas

-

Raw material:

-

Limestone Dolomite Chromite Iron Ore

-

Color:

-

Grey

-

Spare parts:

-

Lile Long Time

-

Advantage:

-

High Efficiency Low Energy

-

Factory Visit:

-

Round Trip Car Picking

-

Capacity:

-

100-3000TPD

-

Kiln Type:

-

Horizontal Cement Kiln

Quick Details

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

China

-

Brand Name:

-

zhongke

-

Voltage:

-

as actual situation

-

Power:

-

55 kw

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

188 kg

-

Keyword:

-

cement kiln

-

Application:

-

Cement Clinker

-

Fuel:

-

Coal,Nature Gas

-

Raw material:

-

Limestone Dolomite Chromite Iron Ore

-

Color:

-

Grey

-

Spare parts:

-

Lile Long Time

-

Advantage:

-

High Efficiency Low Energy

-

Factory Visit:

-

Round Trip Car Picking

-

Capacity:

-

100-3000TPD

-

Kiln Type:

-

Horizontal Cement Kiln

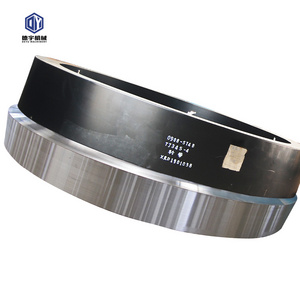

Description of

limestone

Rotary Kiln

Rotary Kiln refers to rotating calcination kiln, belongs to construction material equipment. According to different materials, rotary kiln can be divided into cement kiln, metallurgy chemical kiln and lime kiln. The cement kiln is used for makeing cement clinker and there are dry and wet methods to make cement. Metallurgy chemical kiln is applied in metallurgy industries and ironworks for lean iron ore, chromium ore and ferronickel ore calcination. Lime kiln is mainly used for calcine dolomite and active lime which is used in steel plant and ferroalloy factory.

Features of

limestone

Rotary Kiln

Rotary kiln has simply structure, easy operation in producing, less wearing parts, high efficiency,it's used in the cement plant to calcine high grade cement, at the same time can be used in metallurgy,chemical,constructure ect. rotary kiln features in strong structure, stable operation, high-quality products from the kiln, and we can offers advanced efficient shaft preheater, five-grade cyclone preheater.

Working Principle of

limestone

Rotary Kiln

1. With a certain slope to the level, the whole kiln body is supported by rollers and fitted with thrust rollers to control up and down movement of the kiln body.

2. Besides main driving unit for driving system, it is also fitted with the auxiliary driving unit so as to ensure the kiln body still can rotating when the main motor is powered off and prevent it from deforming.

3. The kiln head adopts housing type sealing and kiln rear uses axial contact sealing unit so that reliability of sealing could be ensured.

Technical Parameters

|

category

|

model

|

Cylinder diameter

(mm) |

cylinder length

(mm) |

inclination

(%) |

capacity

(t/h) |

rotate speed

(rpm) |

power

(kw) |

weight

(t) |

|

Straight

rotary

kiln

|

YZ1225

|

1200

|

2500

|

|

3

|

|

22

|

34

|

|

|

YZ1632

|

1600

|

3200

|

|

3.5

|

|

15

|

46.82

|

|

|

YZ1828

|

1800

|

2800

|

|

4

|

|

30

|

59.39

|

|

|

YZ1845

|

1800

|

4500

|

|

4.5

|

|

30

|

80

|

|

|

YZ1636

|

1600

|

36000

|

4

|

1.2~1.9

|

0.26~2.61

|

22

|

51.023

|

|

|

YZ1939

|

1900

|

39000

|

4

|

1.6~3.4

|

0.31~2.82

|

37

|

70.704

|

|

|

YZ2044

|

2000

|

44000

|

3.5

|

2.4~4

|

0.22~2.26

|

37

|

97.135

|

|

|

YZ2245

|

2200

|

4500

|

3.5

|

3.2~5.3

|

0.23~2.25

|

45

|

125.462

|

|

|

YZ2550

|

2500

|

50000

|

3.5

|

6.2~7.4

|

0.68~1.45

|

55

|

179.606

|

|

|

YZ2555

|

2500

|

55000

|

3

|

7.3~9.8

|

0.79~2.38

|

55

|

191.203

|

|

|

YZ2820

|

2800

|

20000

|

4

|

15~18

|

0.8~1.45

|

75

|

186.373

|

|

|

YZ3028

|

3000

|

28000

|

4

|

18~23

|

0.8~1.45

|

75

|

180.737

|

|

|

YZ3060

|

3000

|

60000

|

3.5

|

16~20

|

0.49~2.41

|

90

|

272.510

|

|

|

YZ3226

|

3200

|

26000

|

4

|

22~27

|

0.8~1.45

|

90

|

185.107

|

|

|

YZ3255

|

3200

|

55000

|

3.5

|

17~23

|

0.1~1.52

|

75

|

271.673

|

|

|

YZ3529

|

3500

|

29000

|

4

|

28~40

|

0.16~1.38

|

110

|

238.031

|

|

|

YZ3560

|

3500

|

60000

|

3.5

|

28~40

|

0.65~2.25

|

125

|

347.872

|

|

|

YZ4030

|

4000

|

30000

|

4

|

52~70

|

0.38~3.52

|

160

|

415.103

|

|

|

YZ4060

|

4000

|

60000

|

3.5

|

55`78

|

0.38~3.52

|

315

|

514.223

|

|

|

YZ4262

|

4200

|

62000

|

3.5

|

80~105

|

0.38~3.52

|

315

|

541.615

|

|

|

YZ4565

|

4500

|

65000

|

3.5

|

110~140

|

0.38~3.52

|

420

|

609.526

|

|

|

YZ4772

|

4700

|

72000

|

3.5

|

150~190

|

0.38~3.52

|

550

|

795.325

|

|

Diameter

changes rotary kiln |

YB1626

|

1600/1400

|

26000

|

4

|

0.7~1.1

|

0.41~3.85

|

18.5

|

38.621

|

|

|

YB1939

|

1900/1600

|

39000

|

4

|

2.2~2.7

|

0.27~2.58

|

22

|

60.841

|

|

|

YB2245

|

2200/2000

|

45000

|

3.5

|

2.5~3.5

|

0.25~2.28

|

30

|

88632

|

|

|

YB2545

|

2500/2200

|

45000

|

3.5

|

4.5~6.2

|

0.25~2.18

|

45

|

102.367

|

|

|

YB2845

|

2800/2500

|

45000

|

3.5

|

7.5~10

|

0.68~1.45

|

55

|

192.622

|

|

|

YB3560

|

3500/3000

|

60000

|

3.5

|

23`32

|

0.65~2.28

|

125

|

310.263

|

Technology Introduction

The rotary kiln produced by Zhongke has the calcining system equipment through technology innovation, which adopts the most advanced hydraulic catch wheel, high precision of measurement piston pump, flow speed control valve, and contact graphite piece of sealing device at home and abroad, In order to improve the degree of automation, kiln head adopts industrial TV watching fire, analog fluorescent screen for process flow, and calcination zone adopts the infrared scanner, directly reflecting the calcination situation in computer . All these new technology has a strong intuitive sense in use, easy to operate. Reliable and stable thermal condition improves the operation rate of the equipment. Compared with the same specification of equipment, the operation rate increases by 10%, the yield increases by 5%-10%, and the heat consumption decreases by 15%.

Dolomite Platinum Marble Calcite Calcium ore

Chromium ore Cobalt ore Granite talc Chemical Industry

Building material Gold mine Phosphate rock Bauxite Aluminum ore

Gangue Magnesium ore Manganese ore Nickel ore Bentonite

Product details

Our products have the following six major features,so that we can lead other manufacturers at home and abroad.

Installation Site

More Products

Packaging & Shipping

Packaging Details:

We will make different packaging according to different machine sizes .standard international export packing, container, wooden box.

Delivery Time:

We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 20 to 30 working days.

Our factory is capable of shipping large machine even more than 100 tons

Hot Searches