- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.8-1.2mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KYT

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Weight:

-

3500 kg

-

Feeding width:

-

According to client's requirement, According to client's requirement

-

Product name:

-

alvanized Shutter Door Sliding Guide Rails Making Machine

-

Roller material:

-

45#steel Chrome Plated

-

Raw material:

-

PPGI

-

Control system:

-

PLC(detla) System

-

Thickness:

-

0.8-1.2mm

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting type:

-

Hydraulic Cutting

-

Machine type:

-

Roll Forming Mahcine

-

Advantage:

-

High Efficent

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.8-1.2mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KYT

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Weight:

-

3500 kg

-

Feeding width:

-

According to client's requirement, According to client's requirement

-

Product name:

-

alvanized Shutter Door Sliding Guide Rails Making Machine

-

Roller material:

-

45#steel Chrome Plated

-

Raw material:

-

PPGI

-

Control system:

-

PLC(detla) System

-

Thickness:

-

0.8-1.2mm

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting type:

-

Hydraulic Cutting

-

Machine type:

-

Roll Forming Mahcine

-

Advantage:

-

High Efficent

Product Description

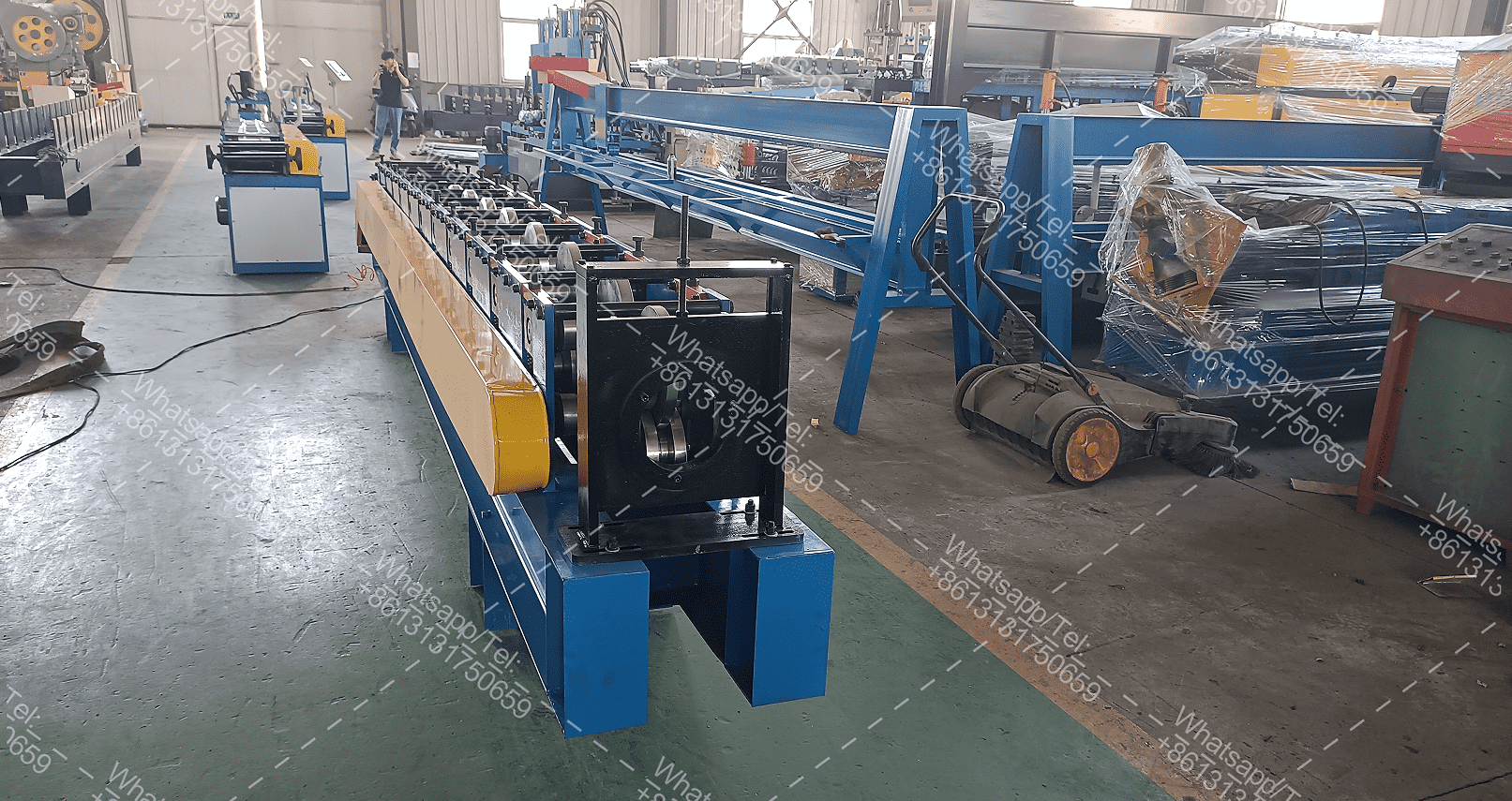

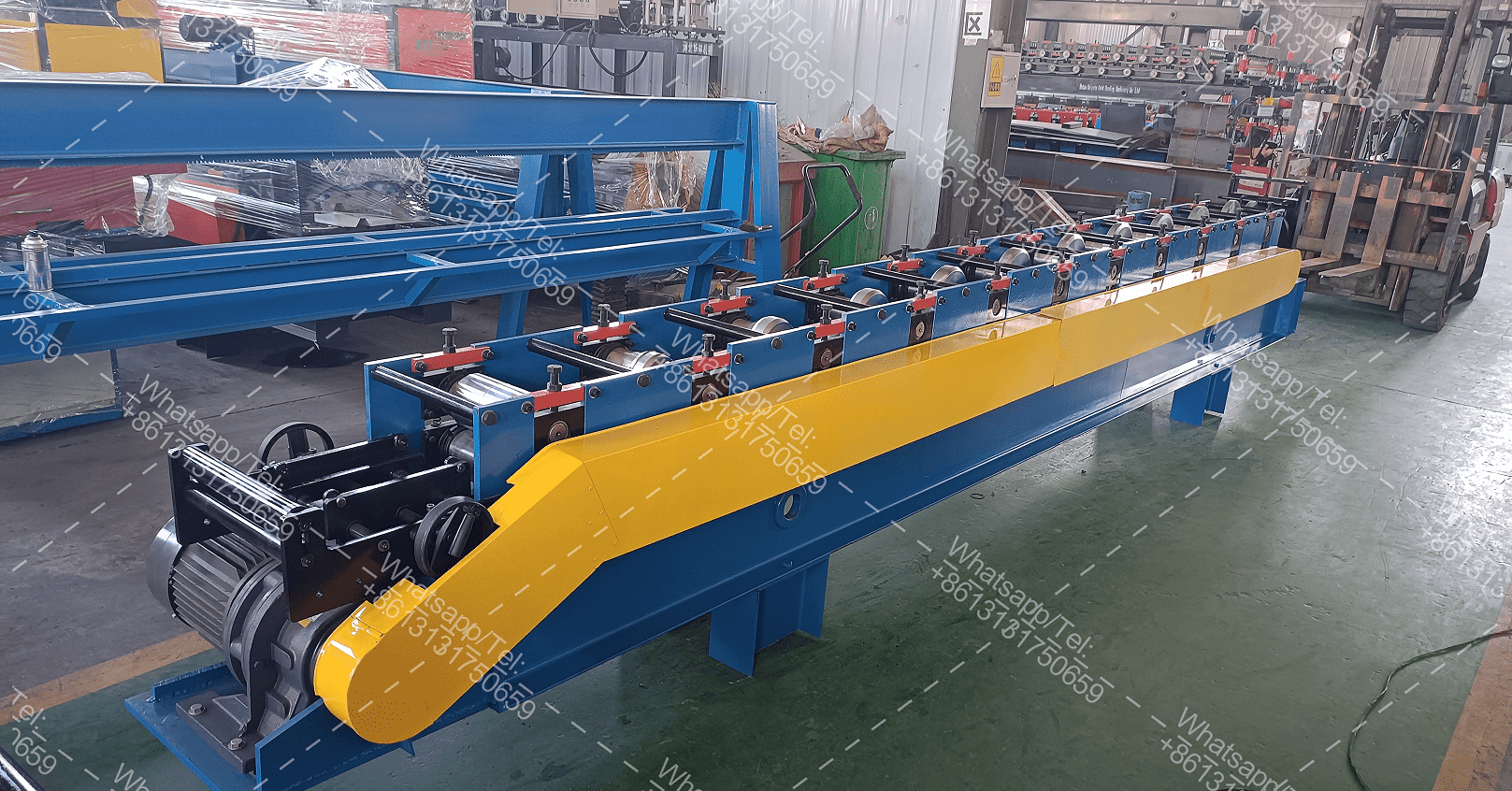

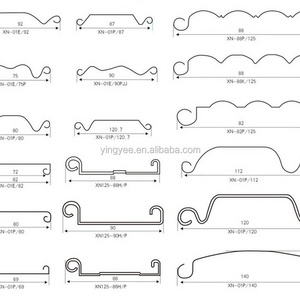

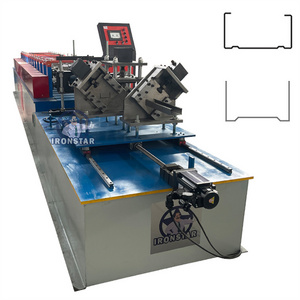

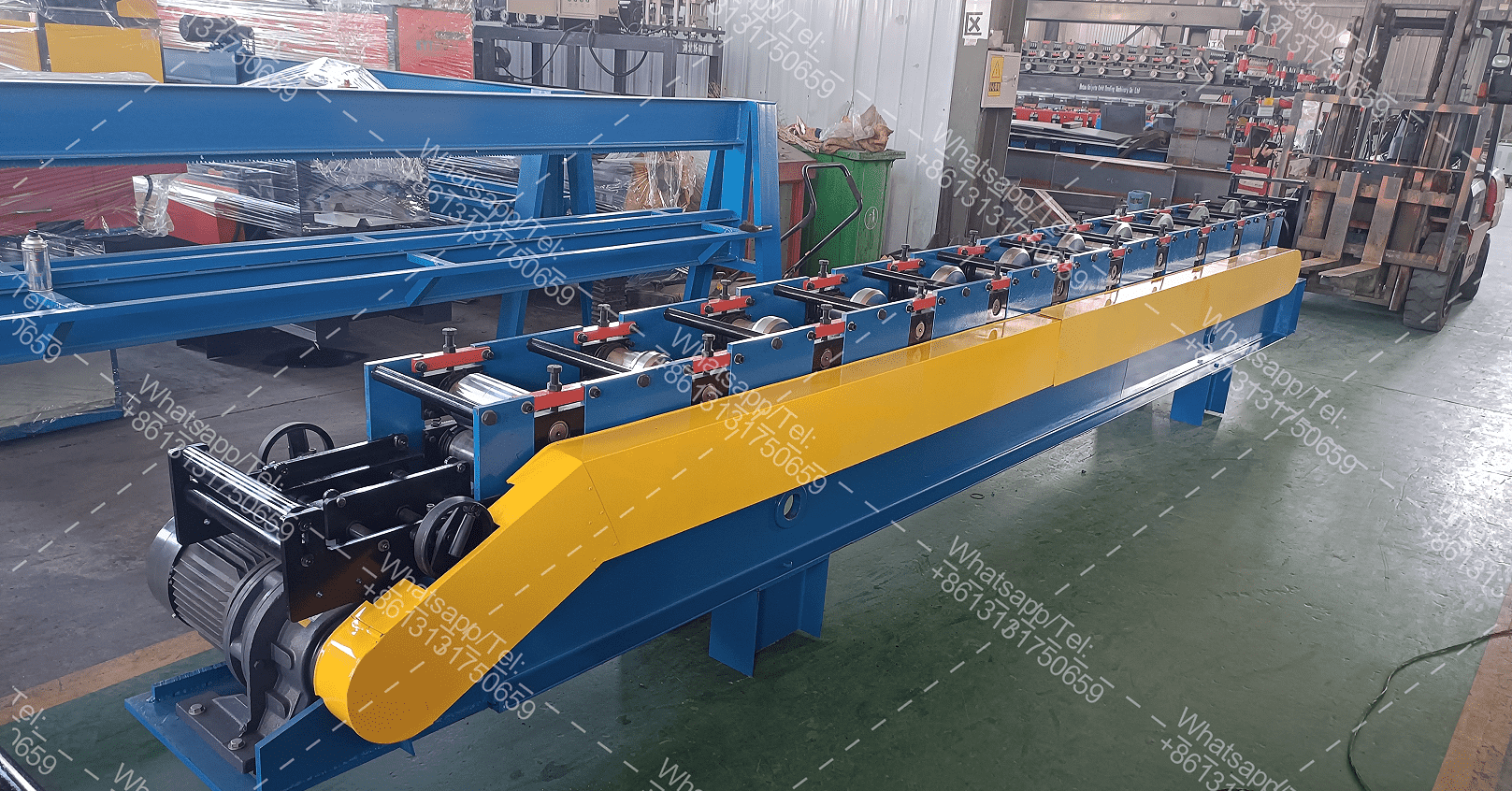

Metal shutter side guide roll forming machine

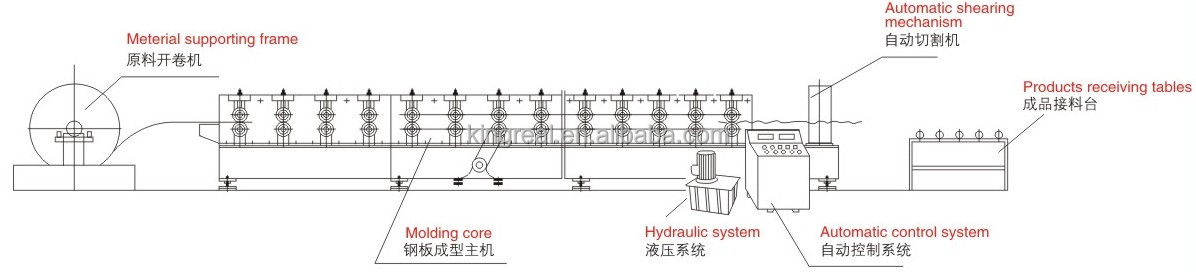

The machine consists of several components, including a decoiler, a feeding unit, a roll forming unit, a punching unit, a cutting unit, a control system, and a hydraulic system.

Specification

The price is only a reference, specific to the actual parameters, different speed, thickness, row number and other factors will lead to different prices.

|

NO.

|

TYPE

|

|

SPECIFICATION

|

|

||

|

1

|

Raw

Material

|

Type

|

Colored steel plate

|

|

||

|

|

|

Feeding width

|

According to client's request

|

|

||

|

|

|

Thickness

|

0.8-1.2mm

|

|

||

|

2

|

Main

Body

|

Shaft material

|

High grade 45#steel

|

|

||

|

|

|

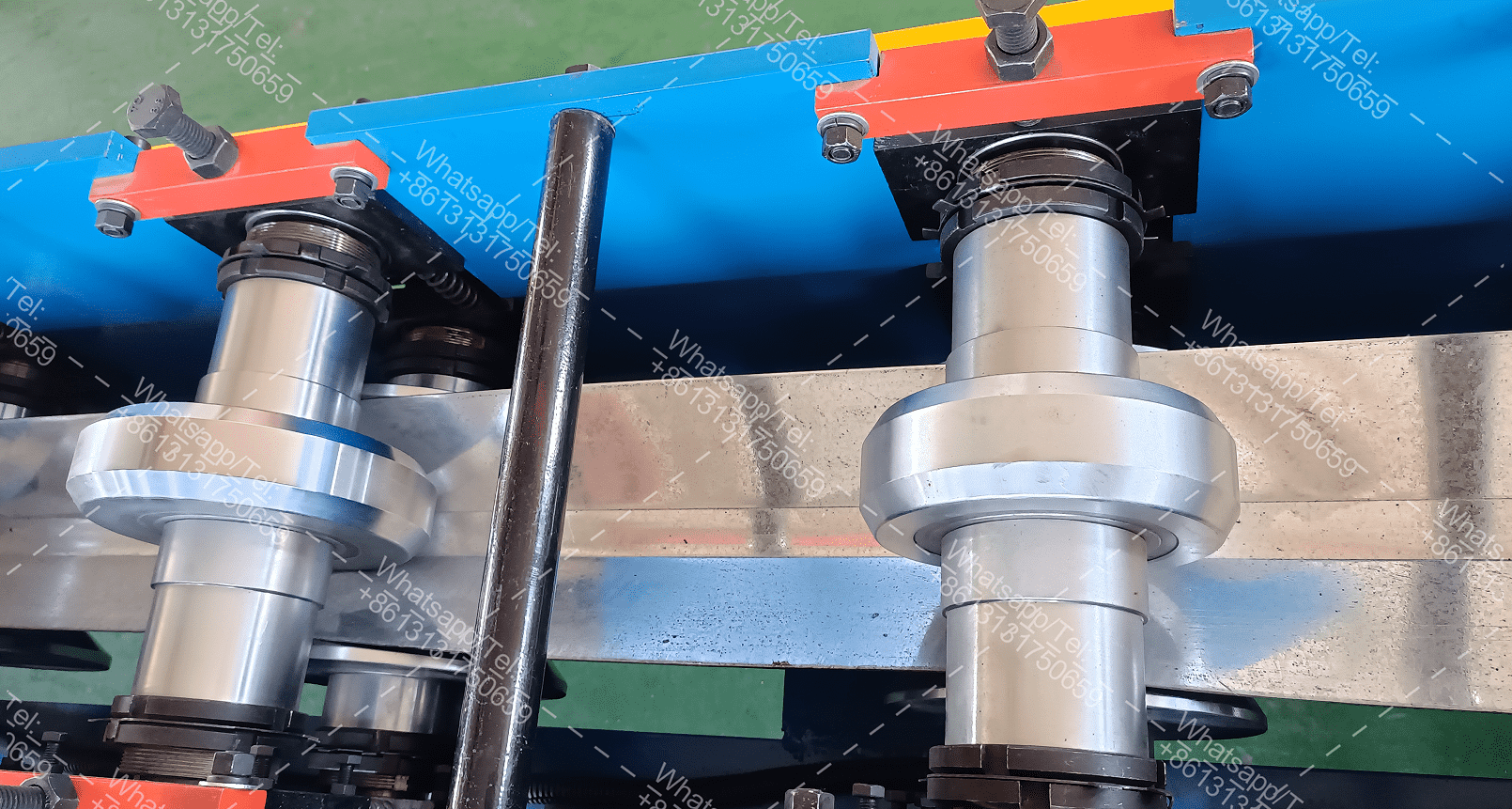

Roller material

|

High grade 45#steel,hard treatment and polishing (plated chrome on surface)

|

|

||

|

|

|

Working speed

|

8-12m/min

|

|

||

|

|

|

Size(L*M*H)

|

According to client's request

|

|

||

|

|

|

Weight

|

3500kg

|

|

||

|

3

|

Power

|

Power

|

3kw

|

|

||

|

|

|

Voltage

|

380v 50Hz or as customized

|

|

||

|

4

|

PLC

Control

System

|

Language

|

English and Chinese or as your requirement

|

|

||

|

|

|

Operation

|

Manual and Automatic

|

|

||

|

5

|

Cutting

Device

|

Cutting type

|

Hydraulic Cutting

|

|

||

Processing Flow

Uncoiling → Feeding And Leveling →Punching/Pre-Shearing→Roll Forming → Auto Cutting →Products Receiving Table

Component Of Machine

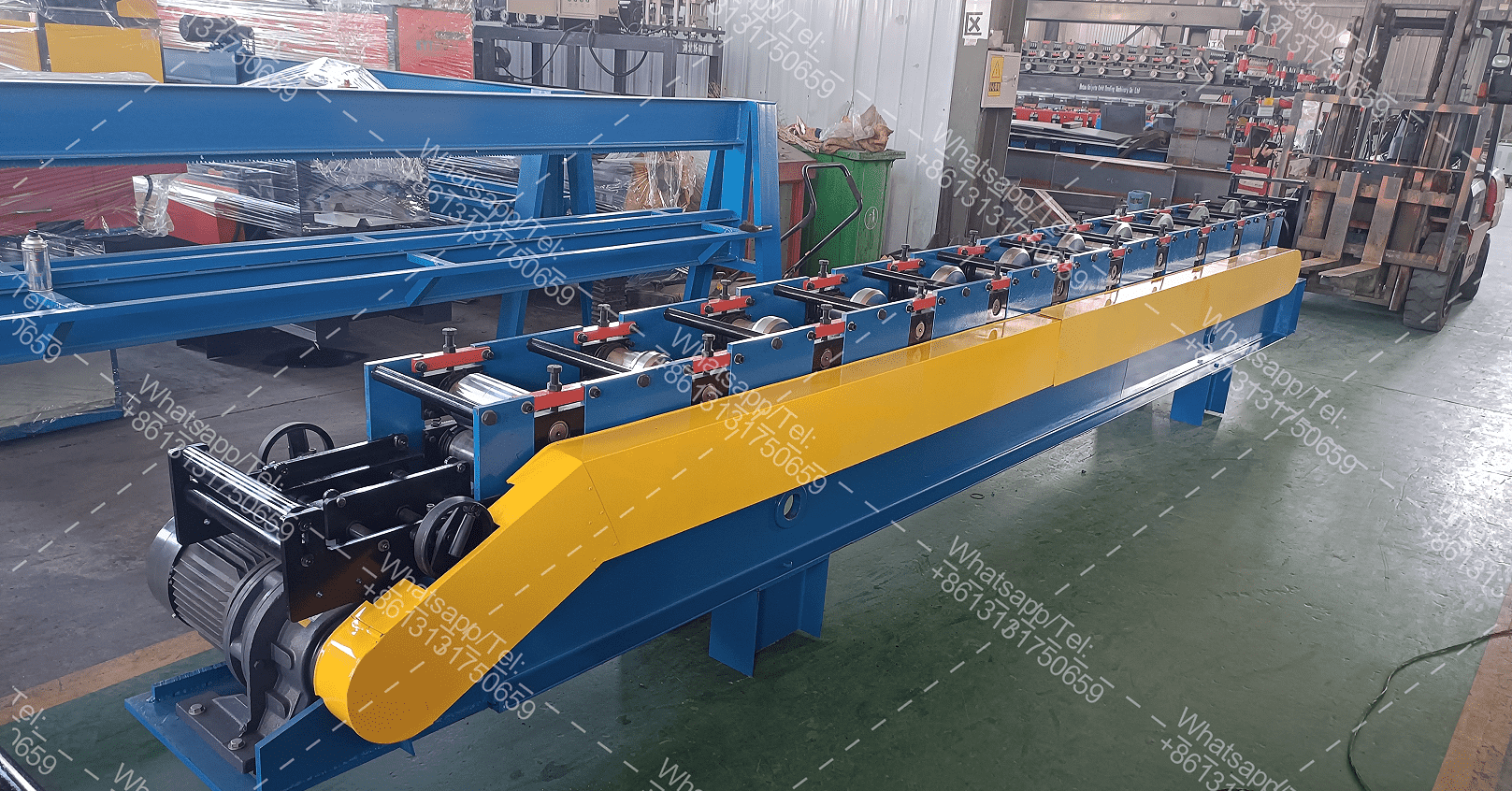

Main Forming Machine

After being forged, polished, heat-treated and finally chromeplated, they are very solid and not easy to wear. At the same time,the roof tiles are smooth without burrs

Hydraulic cutting

Once the metal strip has been formed into the desired profile, a cut-off system is used to separate the finished product from the remaining strip. stable cutting with high speed and low noise.

Decoiler

Mainly used to support steel coils, and manually uncoil and straighten the coil into the feeding table.

Oil Pump

Oil pumps are typically powered by an electric motor and connected to a tank that stores the oil. The pump draws oil from the tank and distributes it to various parts through fittings.

Receiving Table

Receiving table is to catch the pressed steel plate to prevent collision caused by the steel plate directly falling to the ground.

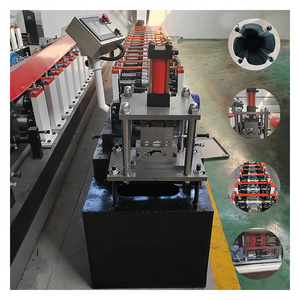

PLC Control System

It facilitates fully automatic production of machines and can set up different language systems according to customer needs

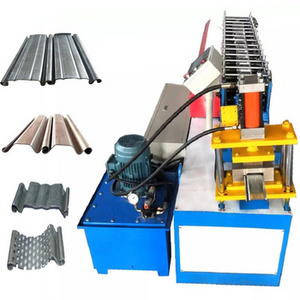

Related products

Shutter door roll forming machine with punching

This kind of machine used to produce shutter door with holes,g

eneral holes can be installed with molds on the machine. Small holes like the ones in the picture below require a punching machine to complete.

Shutter door roll forming machine with embossing

This kind of machine used to produce shutter door with embossing,t

he required patterns can be customized according to customer needs, and it can be completed by simply installing a set of wheels on the machine.

PU foam shutter door roll forming machine

This machine can produce composite doors. Materials can be added while producing the doors to provide fire protection and wind resistance.

Australia style shutter door roll forming machine

This machine usually used with a seaming machine,m

ake the two slats better connected together.

Guide rail roll forming machine

This machine produce guide rail,guide rail

are used on both sides of the rolling shutter door to help the rolling shutter door slide better.

Bottom strip of shtter door roll forming machine

The bottom rail is used at the bottom of the rolling shutter door to better fix the rolling shutter door.

PACKING & DELIVERY

1.We will wipe anti rust oil for the whole machine .

2.Plc controller will be covered by foam film

3.Spare parts are some small parts are packed in a wodden case.

4.All componenets are fixed well by steel wire with container.

Hot Searches