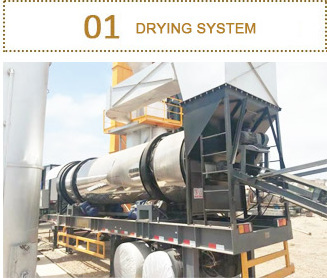

1. Adopts four sets of famous powerful direct-connected gear motors to drive the drying drum;

2. Optimized blades make the drying process more balance with higher heat utilization rate;

3. Drying drum is covered by thermal insulation material and stainless steel skin to avoid heat loss;

4. Well calculated and carefully heat-treated drying drum, world-class bearings have a long service life and stable performance.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

412kw

-

Weight:

-

205 kg

-

After-sales Service Provided:

-

No after-sales service

-

Product name:

-

Mobile Asphalt Mixing Plant

-

Type:

-

Mobile Batch Mix

-

Mixing Type:

-

Hot Asphalt Batching Plant

-

Capacity:

-

120t/h

-

Application:

-

Construction Industry

-

Burner:

-

Oil

-

Control system:

-

PLC+colorized Touching Screen

-

Color:

-

Client's Customized

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sinoroader

-

Voltage:

-

220V/380V-50Hz (adjustable)

-

Power:

-

412kw

-

Weight:

-

205 kg

-

After-sales Service Provided:

-

No after-sales service

-

Product name:

-

Mobile Asphalt Mixing Plant

-

Type:

-

Mobile Batch Mix

-

Mixing Type:

-

Hot Asphalt Batching Plant

-

Capacity:

-

120t/h

-

Application:

-

Construction Industry

-

Burner:

-

Oil

-

Control system:

-

PLC+colorized Touching Screen

-

Color:

-

Client's Customized

-

After Warranty Service:

-

Video technical support

|

Model

|

|

YLB1000

|

YLB1500

|

YLB2000

|

|||

|

Capacity

|

|

80t/h

|

120t/h

|

160t/h

|

|||

|

Mixer Capacity

|

|

1000kg/batch

|

1500kg/batch

|

2000kg/batch

|

|||

|

Fuel Consumption

|

|

Diesel consumption: 5.5-7 kg/ton

|

|

|

|||

|

Weighing Precision

|

|

Hot aggregate: ±0.5%; bitumen: ±0.3%; filler: ±0.2%

|

|

|

|||

|

Hot Asphalt Temperature

|

|

130℃-165℃ (adjustable)

|

|

|

|||

|

Air Emissions

|

|

≤ 20mg/Nm³

|

|

|

|||

|

Working Noise

|

|

≤ 70db(A)

|

|

|

|||

|

Operation

|

|

Full Auto/Manual Operation

|

|

|

|||

|

Installation Power

|

|

241kW

|

330kW

|

412kW

|

|||

|

Voltage

|

|

220V/380V-50Hz (adjustable)

|

|

|

|||

|

Plant Covering Area

|

Length

|

40m

|

40m

|

42m

|

|||

|

|

Width

|

28m

|

32m

|

32m

|

|||

|

|

Height

|

15m

|

16m

|

16m

|

|||

|

Documents

|

|

Lay-Out/ Electric Circuit Diagram; Chinese-English Operation Manual; Qualification Certificate.

|

|

|

|||

1. Double dust collecting system, European emission standards;

2. Pulsating dust removal method, energy saving and efficient;

3. Durable key components;

4. Safety protection, intelligent inspection.

2. Pulsating dust removal method, energy saving and efficient;

3. Durable key components;

4. Safety protection, intelligent inspection.

1. Sturdy and durable, high intensity and remarkable screening effect;

2. Screen mesh easy to maintain and replace, time-saving;

3. Frequency and amplitude perfectly matched, over 95% grading precision, competent to any severe working situation,

high-temperature resistance and excellent productivity;

4. Best design to guarantee the best screening result.

a. Adopts self-synchronizing driving technology, maintenance-free and environmental;

b. Patent enhanced drivable bridge structure design, tough and protective for screening components;

c. Famous vibrating motor.

2. Screen mesh easy to maintain and replace, time-saving;

3. Frequency and amplitude perfectly matched, over 95% grading precision, competent to any severe working situation,

high-temperature resistance and excellent productivity;

4. Best design to guarantee the best screening result.

a. Adopts self-synchronizing driving technology, maintenance-free and environmental;

b. Patent enhanced drivable bridge structure design, tough and protective for screening components;

c. Famous vibrating motor.

1. Simulating optimization of material mixing movement speed;

2. Ensures each batch is totally and equally mixed with 25% mixing efficiency enhancement and 20% energy consumption reduction;

3. High productivity double-shaft mixer;

2. Ensures each batch is totally and equally mixed with 25% mixing efficiency enhancement and 20% energy consumption reduction;

3. High productivity double-shaft mixer;

World famous brand (TOLEDO) weighment devices are adopted to make sure that the measurement error of aggregates is below 0.5%, and

the measurement error of bitumen and filler is below 0.25%.

the measurement error of bitumen and filler is below 0.25%.

1.The storage silo has heating device to keep the temperature and quality of final mixture;

2. The silo has anti-blocking device to keep asphalt quality.

2. The silo has anti-blocking device to keep asphalt quality.

Q1.Are you factory or a trading company?

A: We are factory and a professional manufacturer of asphalt mixing plant.

Q2: What is the delivery time?

A: 30-50days after receiving advance payment

Q3: What is the payment terms?

A: T/T. L/C are all accept.

Q4: Can I visit your factory?

A:Of course. We warmly welcome you to visit our factory. And we provide you great services like airport pick up, hotel booking,

etc.

Q5: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and

thoroughly solve your problems.

Q6: Which countries your equipment have been exported?

A:Thailand, Philippines, Indonesia, Myanmar, Russia, Bangladesh, Kazakhstan, Uzbekistan, Russia, Romania, Somalia, Kenya, Malawi,

Nigeria, Togo, Mozambique, Oman, South Africa, America, Peru, Chile, Colombia, Venezuela, Australia, etc.

Q7: Do you provide overseas erection and training service?

A:Yes, we can send experienced engineers to your country, guide erection and commissioning and train your workers how to operate

the plant.

Q8: How about the price?

A: We are manufactory, not dealer, so we can give you a lower price than those trade companies can.

A: We are factory and a professional manufacturer of asphalt mixing plant.

Q2: What is the delivery time?

A: 30-50days after receiving advance payment

Q3: What is the payment terms?

A: T/T. L/C are all accept.

Q4: Can I visit your factory?

A:Of course. We warmly welcome you to visit our factory. And we provide you great services like airport pick up, hotel booking,

etc.

Q5: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and

thoroughly solve your problems.

Q6: Which countries your equipment have been exported?

A:Thailand, Philippines, Indonesia, Myanmar, Russia, Bangladesh, Kazakhstan, Uzbekistan, Russia, Romania, Somalia, Kenya, Malawi,

Nigeria, Togo, Mozambique, Oman, South Africa, America, Peru, Chile, Colombia, Venezuela, Australia, etc.

Q7: Do you provide overseas erection and training service?

A:Yes, we can send experienced engineers to your country, guide erection and commissioning and train your workers how to operate

the plant.

Q8: How about the price?

A: We are manufactory, not dealer, so we can give you a lower price than those trade companies can.

Hot Searches