Black silicon carbide 54C 53C abrasive grit F30 F54 F70

-

Transport Package:

-

25kgs per bag,1000kgs per Jumbo bag

-

Specification:

-

F16-F220

-

Trademark:

-

HAIXU ABRASIVES

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

China

-

Natural Abrasive Type:

-

Other

-

Artificial Abrasive Type:

-

Silicon Carbide Abrasive Black silicon carbide grit

-

Application:

-

Machinery Metal Parts Auto Parts Other Marble grinding Stone blasting ceramic sandblasting

-

Function:

-

Surface Deburring Surface Finish Other Grinding and buffing Blasting polishing

-

Source:

-

Artificial Abrasives

-

Particle Size:

-

Abrasive Powder Ultrafine F16-F220

-

Hardness:

-

Conventional Abrasive Mohs 9.2

-

Purity:

-

98%,98.5%,99%

-

Bulk density:

-

1.2-1.6g/cm3

-

Specific gravity:

-

3.15-3.2g/cm3

-

Standard:

-

FEPA

-

Mohs hardness:

-

9.15-9.2

-

Quality grade:

-

A grade

-

refractorieness:

-

min 1900 degree

-

Vicker hardness::

-

2940-3200kg/mm2

-

Thermal Conductivity:

-

70-130 W/M.K

-

Payment:

-

L/C T/T Paypal

-

Export Port:

-

Tianjin

-

Output:

-

800 Tons per Month

-

Model NO:

-

F16-F220

Quick Details

-

Purity:

-

98%,98.5%,99%

-

Bulk density:

-

1.2-1.6g/cm3

-

Specific gravity:

-

3.15-3.2g/cm3

-

Standard:

-

FEPA

-

Mohs hardness:

-

9.15-9.2

-

Quality grade:

-

A grade

-

refractorieness:

-

min 1900 degree

-

Vicker hardness::

-

2940-3200kg/mm2

-

Thermal Conductivity:

-

70-130 W/M.K

Black silicon carbide 54C 53C abrasive grit F30 F54 F70

Products Descripition

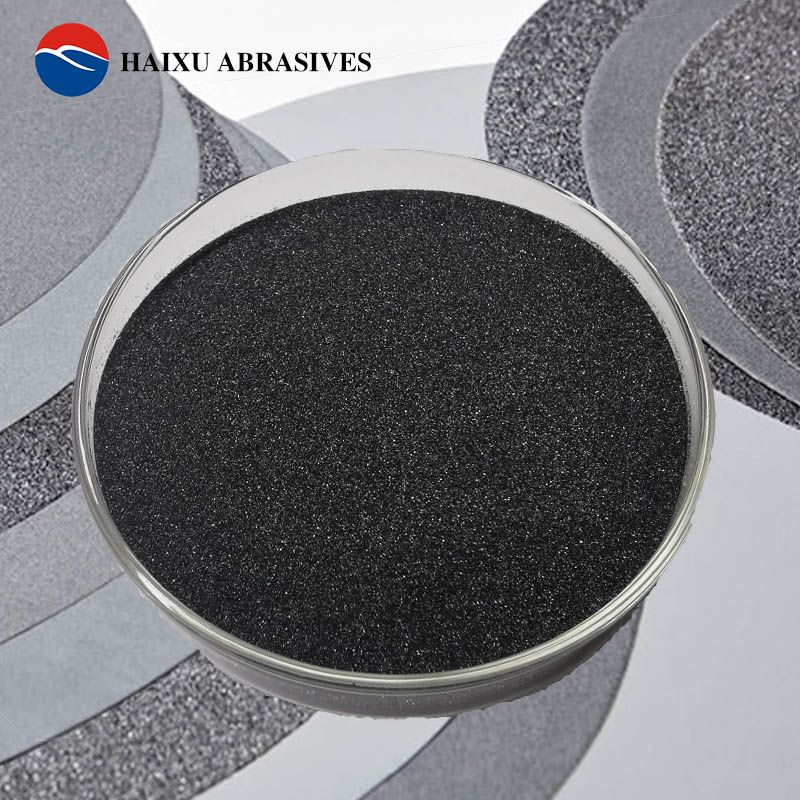

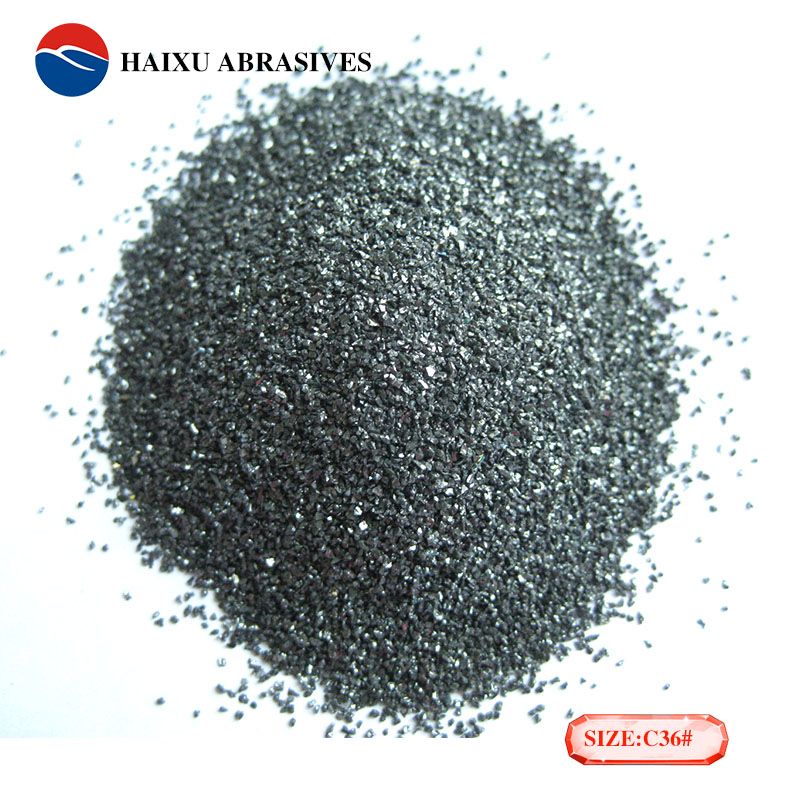

Black silicon carbide abrasive powder gets a superior finishing effect on glass, marble, jade, and ceramics. It is featured by the high hardness of Mohs scale 9.2 and Vicker hardness 3000-3100kg/mm2. Black SiC abrasive powder is made from suspension treatment. It gets a uniform crystal size. So it can achieve a fine and consistent lapping surface.

Advantage Introduction

Product Feature of 98% 98.5% Black SiC powder 60mesh 120mesh 150mesh from China

- High hardness with Mohs 9.2-9.3. Even at 2000℃, it still gets high strength.

- Good oxidation resistance and chemical stability at high temperatures.

- High thermal conductivity and low thermal expansion rate.

- High SiC purity and cleanness with low impurity and low magnetics.

- High bulk density.

- Particle size consistency.

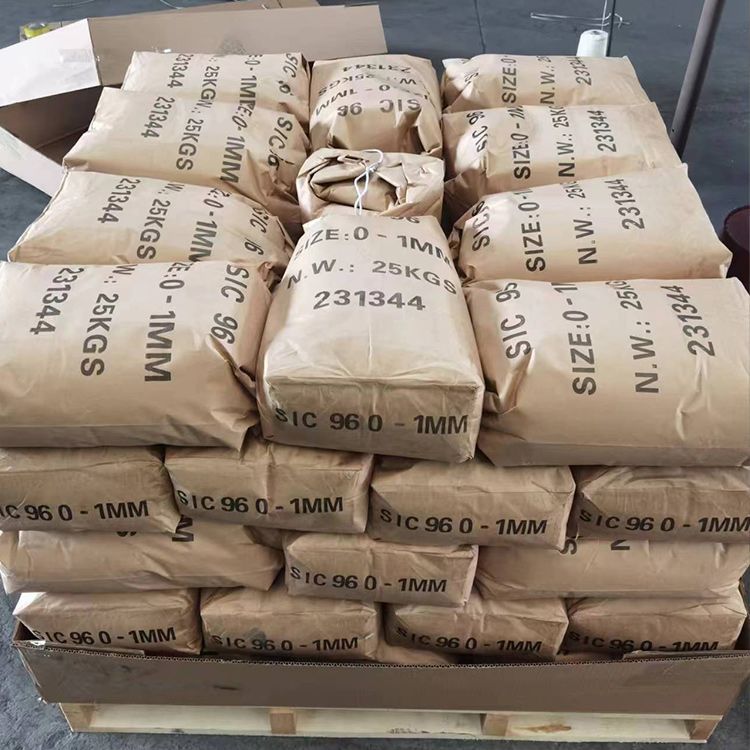

Product Image

Product Index

Typical physical properties of 98% 98.5% Black SiC powder 60mesh 120mesh 150mesh from China

| Chemical composition | SiC:98-99.2% |

| Mohs Hardness: | 9.2-9.3 |

| Vicker hardness: | 2940-3200kg/mm2 |

| Specific Gravity: | 3.15-3.20 g/cm3 |

| Bulk density(LPD depends on the size): | 0.8-1.5 g/cm3 |

| Melting Point: | dissociated at about 2300 °C |

| Maximum service temperature: | 1900℃ |

| Particle shape: | Hexagonal |

| Modulus of Elasticity | 58-65x106 psi |

| Coefficient of Thermal Expansion | 3.9-4.5 x10-6 /°C |

| Thermal Conductivity (at 25°C) | 70-130 W/M·K |

| Raw material | Petroleum coke,quartz sand |

Specification

Typical chemical composition of 98% 98.5% Black SiC powder 60mesh 120mesh 150mesh from China

Grade | ds50-value in μm | Typical Chemical Composition(%) | ||

| SiC | FC | Fe2O3 | ||

F 230 | 53.0 ± 3 | 99.4 | 0.1 | 0.06 |

F 240 | 44.5 ± 2 | 99.4 | 0.11 | 0.05 |

F 280 | 36.5 ± 1.5 | 99.4 | 0.12 | 0.06 |

F 320 | 29.2 ± 1.5 | 99.3 | 0.06 | 0.05 |

F 360 | 22.8 ± 1.5 | 99.2 | 0.15 | 0.05 |

F 400 | 17.3 ± 1 | 99.1 | 0.08 | 0.05 |

F 500 | 12.8 ± 1 | 98.67 | 0.06 | 0.06 |

F 600 | 9.3 ± 1 | 98.62 | 0.05 | 0.07 |

F 800 | 6.5 ± 1 | 98.66 | 0.11 | 0.05 |

F 1000 | 4.5 ± 0.8 | 98.63 | 0.13 | 0.07 |

F 1200 | 3.0 ± 0.5 | 98.59 | 0.17 | 0.08 |

Usage

Grinding and polishing gem, jade, and jewelry.

Polishing glass shape and surface.

Lapping electronic ceramic components.

The raw material of silicon carbide abrasive tools.

Production Process

Packaging&Shipping

- 25 kgs/PVC Bag with plastic inner bag.

- 1MT /Jumbo Bag

- 25 kgs/PVC Bag,40Bags/Jumbo Bag

- 1 Metric Ton/Jumbo Bag/Pallet

- 25 kgs/paper bag,1MT/Pallet

- Other customized packages are available

FAQ:

Q: Are you a manufacturer?

A: We are a manufacturer of both black silicon carbide and green silicon carbide materials. We began to produce silicon carbide powder since 1999.

Q: What grade of silicon carbide do you have?

A: We have several grades of silicon carbide powder including refractory grade, abrasive grade,etc.

Q: How will you check silicon carbide quality before delivery?

A: We will check the chemical composition, and cleanness of the carborundum grain and powder. And inspect the gradation, bulk density of SiC grain and powder.

Q: Do you support third-party quality inspection?

A: Yes, we are open to getting a third party quality test before delivery.

Q: Is the silicon carbide you supply reclaimed material?

A: No. We do the melting process by ourselves and don’t have reclaimed silicon carbide.

Q: What is the HS code of silicon carbide abrasive powder?

A: The HS code is 2849200000.

Q: Is there any restriction to export silicon carbide from China?

A: Yes, it needs to provide an export license to Chinese customs. We could provide it and make customs clearance in China.

Q: Are free samples available?

A: Yes, we provide free samples within 1 kg. Customers only need to bear the logistic cost.

Q: What is your annual capacity?

A: Our capacity is 1800-2000MT per month, annually appr. 22000 MT.

Contact:

Ms.Chen

Email: panchen(@)hxabrasive(dot)com

WhatsApp/Wechat: 0086 13526538098