Ultrasonic sealing for cup body, both okay for single or double PE coated paper.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Depai Machinery

-

Voltage:

-

380V/220V

-

Power:

-

4 KW

-

Dimension(L*W*H):

-

2115*1000*1700mm

-

Weight:

-

1800 kg

-

Marketing Type:

-

2024 Hot Sale Product

-

Product Name:

-

Paper Cup Making Machine

-

Model No:

-

DP-CF16

-

Key Selling Point:

-

High Speed, Low Price

-

Application:

-

Paper Industry

-

Advantage:

-

Easy Operation

-

Machine Type:

-

Paper Cup Forming Machine

-

After Warranty Service:

-

Online Video Technical Support

-

Color:

-

Cutomized Color

-

Productivity:

-

80-95 pcs/min

-

Raw material:

-

Single/Double PE Coated Paper

Quick Details

-

Production Capacity:

-

80-95 pcs/min

-

Product Type:

-

Paper Cup Making Machine

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Depai Machinery

-

Voltage:

-

380V/220V

-

Power:

-

4 KW

-

Dimension(L*W*H):

-

2115*1000*1700mm

-

Weight:

-

1800 kg

-

Marketing Type:

-

2024 Hot Sale Product

-

Product Name:

-

Paper Cup Making Machine

-

Model No:

-

DP-CF16

-

Key Selling Point:

-

High Speed, Low Price

-

Application:

-

Paper Industry

-

Advantage:

-

Easy Operation

-

Machine Type:

-

Paper Cup Forming Machine

-

After Warranty Service:

-

Online Video Technical Support

-

Color:

-

Cutomized Color

-

Productivity:

-

80-95 pcs/min

-

Raw material:

-

Single/Double PE Coated Paper

Product Description

High quality double wall paper cup drink cup forming

making machine in stock

DP-CF16 paper cup machine is an automatic machine with multi-working station, which runs a procedure of single PE coated or double PE coated, paper cup fan feeding, cup side welding(by heater or ultrasonic), silicone oil lubrication, bottom punching, bottom preheating, bottom folding, bottom knurling, top curling and cup discharging. It has the function of photocell detection, failure alarm, with the advantage of humanism design, safe operation, easy maintenance and durable running. It is an ideal equipment of making disposable paper cups for all types cups (hot and cold drink, coffee, tea, ice cream cup and so on.)

Specification

|

Type

|

DP-CF16 high speed double PE coated paper cup machine

|

|

|

|

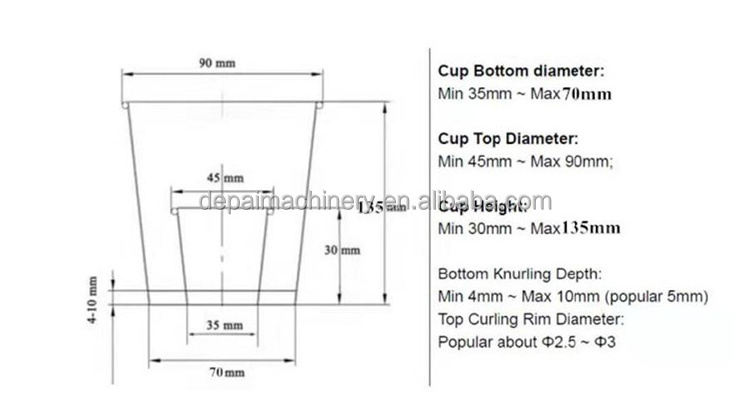

Paper Cup Size

|

2 oz-16 oz

mould exchangeable max cup height: 135 mm max bottom width: 70 mm |

|

|

|

Speed

|

80-95 pcs/min

speed affected by cup size, paper quality and thickness 9 oz, 280 gsm paper cup stable running speed 80 pcs/min |

|

|

|

Power Source

|

50/60HZ, 380V/220V ( better to use 380V, 3 phase )

|

|

|

|

Weight

|

1800kgs

|

|

|

|

Package Size(L*W*H)

|

2115×1000×1700mm

|

|

|

|

Power Source

|

50/60HZ, 380V/220V ( better to use 380V, 3 phase )

|

|

|

|

Raw Material

|

One-side PE coated paper

(popular for hot drink cups) |

one-side or double-side PE coated paper

popular for hot and cold drink cups |

|

|

Total Power

|

4kw

|

6kw

|

|

|

Air Source

|

no need

|

air pressure: 0.4 Mpa;

air out-put: 0.6 m³/minute |

|

|

Cup Side Welding

|

copper heater

|

ultrasonic heater

|

|

|

Cup Bottom Heating

|

heater knurling

|

1 side PE paper by heater knurling;

2 side PE paper by cool device (circle water) knurling |

|

|

Material

|

140-250 gsm

|

140-350 gsm

|

|

Features

1) Simple operation and easy in installation and maintenance.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3) Running in a high automation and intellectualization, no pollution.

4) Can add the cup collector, which can directly automatic collect the cup(extra pay for the collector).

2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3) Running in a high automation and intellectualization, no pollution.

4) Can add the cup collector, which can directly automatic collect the cup(extra pay for the collector).

Paper Cup Diagram

Machine Details

Feeding Unit

Ultrasonic Sealing

Preheating, Knurling, Curling

Cup Bottom Feeding

Cup Discharging

Control Panel

Electric Box

We use famous brand electronic equipment.

Photoelectricity Sensor

Photoelectricity sensor can track every step. Auto alarm when paper fan go short. Auto stop when multi paper fans delivery. Auto alarm when any fault on the machine.

Mechanism and Moving Parts

Main mechanism and moving parts are controlled by quality gears, which is more efficient and more stronger than chain and axis.

New Multi-function Cam Design

Adopt three cam which for control machine fours spare parts running( running stable for sealing paper fan, also difficult broken)

Finished Product

Hot Searches