- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HXJQ

-

Dimension(L*W*H):

-

3600*3600*6000mm

-

Weight:

-

21000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

Casting steel

-

Adaptability:

-

Strong

-

Structure:

-

Maintenance

-

Installation:

-

Under technical guidance

-

Market:

-

Africa, Europe, Asia,etc

-

Factory:

-

50,000 square meters closed workshops

-

Grinding machine:

-

raymond mill, ball mill, coal mill

-

Energy:

-

Saving

-

Certification:

-

ISO9001:2008,CE,GOST,CUTR

Quick Details

-

Marketing Type:

-

Hot Product

-

Capacity(t/h):

-

0.65-615

-

Place of Origin:

-

Henan, China

-

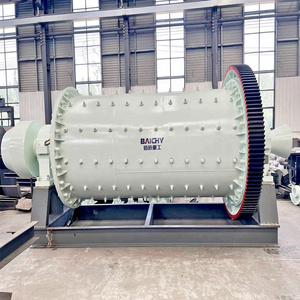

Brand Name:

-

HXJQ

-

Dimension(L*W*H):

-

3600*3600*6000mm

-

Weight:

-

21000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

Casting steel

-

Adaptability:

-

Strong

-

Structure:

-

Maintenance

-

Installation:

-

Under technical guidance

-

Market:

-

Africa, Europe, Asia,etc

-

Factory:

-

50,000 square meters closed workshops

-

Grinding machine:

-

raymond mill, ball mill, coal mill

-

Energy:

-

Saving

-

Certification:

-

ISO9001:2008,CE,GOST,CUTR

3.Advantages

♦ Steel plate chamfering processing

♦ Cylinder takes overall annealing process, eliminating welding stress and prevent deformation.

♦ Flanges on both ends of the cylinder adopt large CNC lathes and special processing technology which fully guarantee concentricity.

♦ The hollow axis adopts the cast steel.

♦ The lining can be replaced.

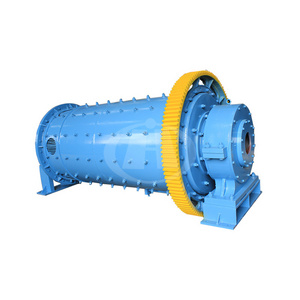

♦ Rotating adopts casting rolling gear.

♦ The barrel body is wearable.

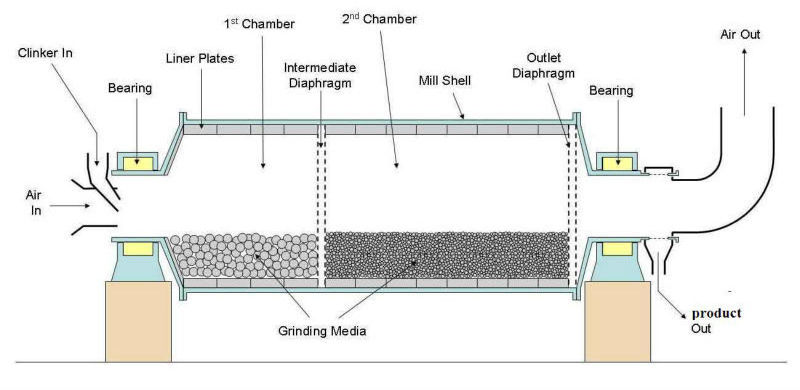

4.Working principle

• This machine is of horizontal cylindrical rotating device, gear transmission, the outer two positions, grate ball mill.

• Material composed of feeding device through the hollow shaft spiral evenly into the mill first warehouse, the warehouse has ladder plate or corrugated plate, built in different specifications of steel ball, cylinder rotate falling after the ball to a certain height, the centrifugal force is generated on the material and grinding effect.

• Material in the first warehouse after reaching coarse grinding, by monolayer partition storehouse board into the second warehouse, the warehouse with a flat plate, inside the steel ball, will further grinding material. Powder through the unloading Bi board, finish grinding homework

Spare parts:

5.Techinical data

Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc. and train shipping is also available. The perfect shipping way and best service with lowest price are always provided for customers.

Working Site

Why Choose Us

1. We are Factory ( NOT Dealer )

All machineries from Henan Hongxing Mining Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service.

So please buy machine from factory.

2. Training & Service

1)Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

2)Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

3)

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

4)In addition,

we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

3. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments.

4. We’d like to recommend a suitable type for you and send you a best quotation.