- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACC machine

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

55m*6m*4.5m

-

Power (kW):

-

400

-

Weight:

-

25000 KG

-

Extruder type:

-

single screw extruder

-

Raw material:

-

HDPE granules

-

Diameter range:

-

630-1200mm

-

Processing Type:

-

Extruding

-

Capacity:

-

Max 2000kg

-

Final product:

-

HDPE pipe

-

Motor type:

-

DC motor

-

Control:

-

PLC touch screen

-

Temperature controller:

-

Solid state

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

150

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACC machine

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

55m*6m*4.5m

-

Power (kW):

-

400

-

Weight:

-

25000 KG

-

Extruder type:

-

single screw extruder

-

Raw material:

-

HDPE granules

-

Diameter range:

-

630-1200mm

-

Processing Type:

-

Extruding

-

Capacity:

-

Max 2000kg

-

Final product:

-

HDPE pipe

-

Motor type:

-

DC motor

-

Control:

-

PLC touch screen

-

Temperature controller:

-

Solid state

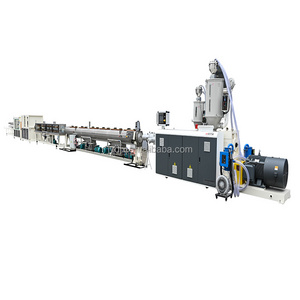

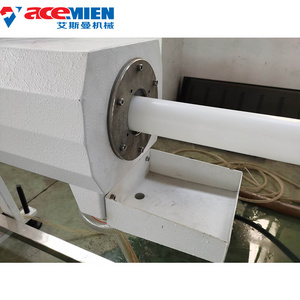

630mm - 1200mm PE plastic pipe extrusion production line

This HDPE/PE pipe production line can be used to produce 630mm-1200mm HDPE pipe.

2.The SJ150 extruder uses high efficiency screw, its L/D is 33:1 , it is equipped with a high-torque motor and has high production efficiency. Vacuum calibration tank and cooling tank are stainless steel, they use high quality vacuum pumps and pumps, with moving rails under the machine for easy operation. The 8-claw haul off machine is frequency controlled, with large clamping force and smooth traction. Cutting machine controlled by the PLC, and it is a circular cut, smooth incision. The machine's electrical uses ABB, Siemens, Omron and Schneider brand components, stable operation and long service life.

| NO. | Machine Name | Qty |

| 1 | Vacuum feeder and dryer hopper | 1 set |

| 2 |

SJ150/33 Single screw extruder

|

1 set |

| 3 | SJ35 Single screw color extruder | 1 set |

| 4 | Mould | 1 set |

| 5 | Vacuum forming tank | 1 set |

| 6 | Cooling water tank | 2 sets |

| 7 | Haul off machine | 1 set |

| 8 | Cutting machine | 1 set |

| 9 | Stacker | 1 set |

| 10 | Electric control cabinet | 1 set |