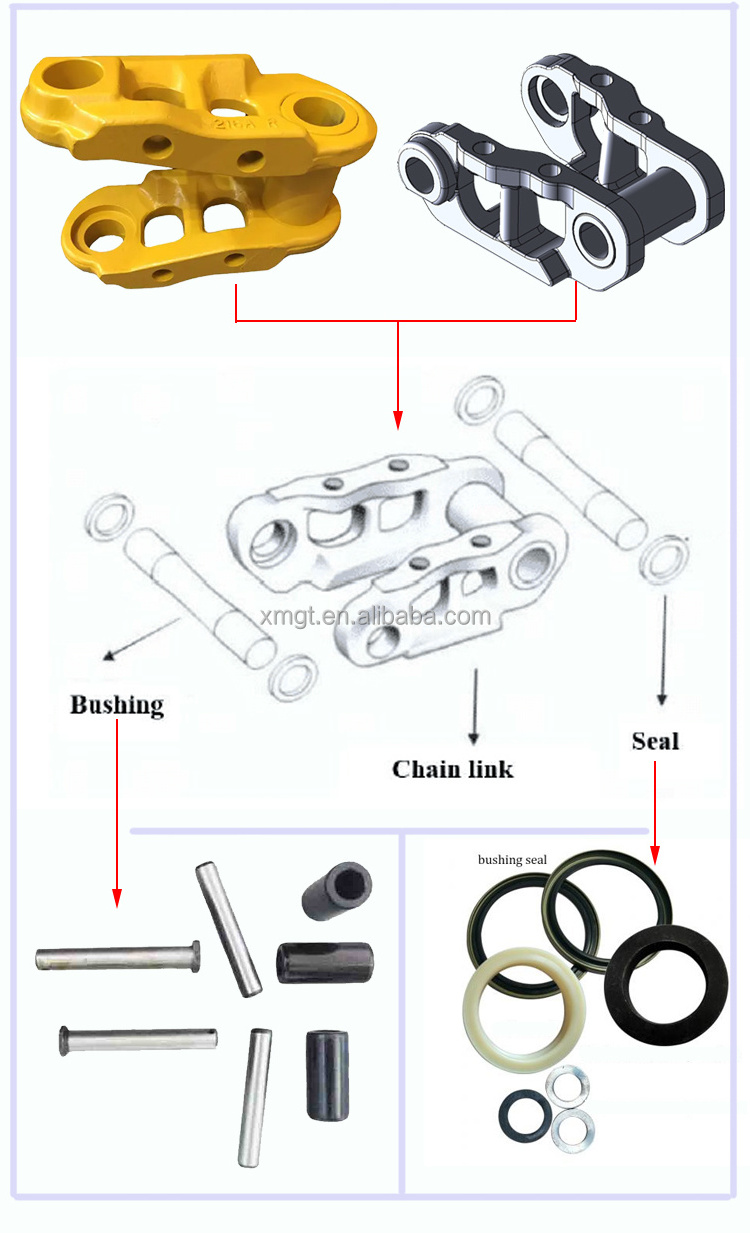

All components (pins, bushings and forged links) are produced with precise tolerance to ensure joint integrity, perfect fit and sealing. Meanwhile, they are fully quenched & tempered and induction hardened at the rail surface of links for higher wear resistance and longer service life.

Our lubricated dozer links are filled by oil to reduce internal friction and wear between pins and bushings for extended wear life under extreme working conditions. Every joint goes through stress test to reduce the risk of leakage while operating. The service life is improved by 30%-50% compared with that of greased type.

We can supply customized chains upon request such as heavy duty and extended wear life chains with bigger bushings with deeper carburized layer and higher links for maximum service life.

- Product Details

- {{item.text}}

Quick Details

-

Finishing:

-

Smooth

-

Name:

-

excavator track link

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

GT excavator track link

-

Certification:

-

ISO9001-9002

-

Finishing:

-

Smooth

-

Name:

-

excavator track link

Product Description

Lubricated Dozer Chains and Dry Chain

Specification

|

Description

|

|

Surface hardening method

|

Surface hardness(HRC)

|

Low Material hardening method

|

Material hardness(Hrc)

|

Hardening depth(mm)

|

Low Material (China)

|

|

Track pin

|

For bulldozer

|

Medium frequency hardening

|

55~59

|

Quenching and Tempering

|

31~37

|

P=171~190 3.0~5.0 P=190 4.0~6.0

|

40Cr

|

|

Track pin

|

For excavator

|

Medium frequency hardening

|

55~59

|

Quenching and Tempering

|

31~37

|

P=171~190 3.0~5.0 P=190 4.0~6.0

|

40Cr

|

|

Track bush

|

For bulldozer

|

Medium frequency hardening

|

54~58

|

Quenching and Tempering

|

28~38

|

P=171~216 3.6~5.0 & 2.7~4.0 P=228 4.7~6.2 & 3.0~4.7

|

40Cr

|

|

Track bush

|

For excavator

|

Medium frequency hardening

|

54~58

|

Quenching and Tempering

|

28~38

|

P=171~216 3.6~5.0 & 2.7~4.0 P=228 4.7~6.2 & 3.0~4.7

|

40Cr

|

|

Track link

|

For bulldozer

|

Medium frequency hardening

|

50~56

|

Quenching and Tempering

|

33~38

|

P=171~175 5.0~10.0 P=190~216 7.0~12.0 P=228 11.0~15.0

|

35MNBHS

|

|

Track link

|

For excavator

|

Medium frequency hardening

|

50~56

|

Quenching and Tempering

|

33~38

|

P=171~175 5.0~10.0 P=190~228 7.0~12.0

|

35MNBHS

|

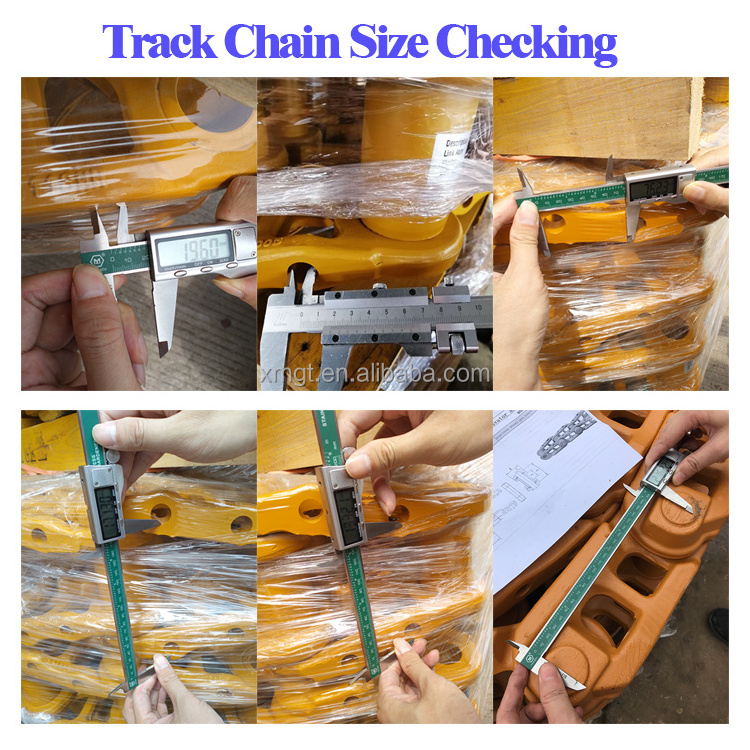

Testing

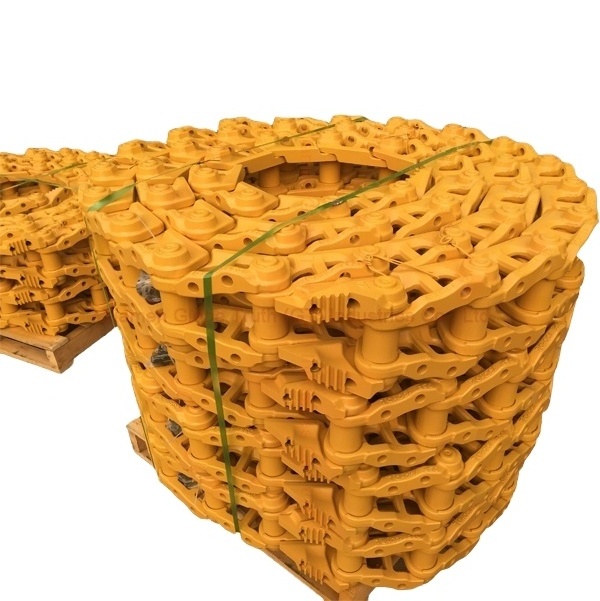

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches