- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

thermal conductive adhesive

-

Other Names:

-

electrically conductive adhesive

-

Appearance:

-

white elastomer

-

Thermal Conductivity:

-

1.6

-

Application:

-

LED ceiling light, LED tubes

-

Packing:

-

80g/tube

-

MOQ:

-

100pcs

-

Payment Terms:

-

T/T or Paypal

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand:

-

Kafuter

-

ITEM:

-

K-5204K

-

Product Name:

-

thermal conductive adhesive

-

Other Names:

-

electrically conductive adhesive

-

Appearance:

-

white elastomer

-

Thermal Conductivity:

-

1.6

-

Application:

-

LED ceiling light, LED tubes

-

Packing:

-

80g/tube

-

MOQ:

-

100pcs

-

Payment Terms:

-

T/T or Paypal

White Grey Dielectric Conductive Silicone Thermal Grease Paste for Heat Sink Component

FEATURES

K-5204K is a reinforced thermally conductive silicone elastomer with great adhesion, insulation and dissipation.

(1) one part, room cure, packing in soft metal tube.

(2) Excellent in cold and high alternating resistance (-60°c~ 280°c).

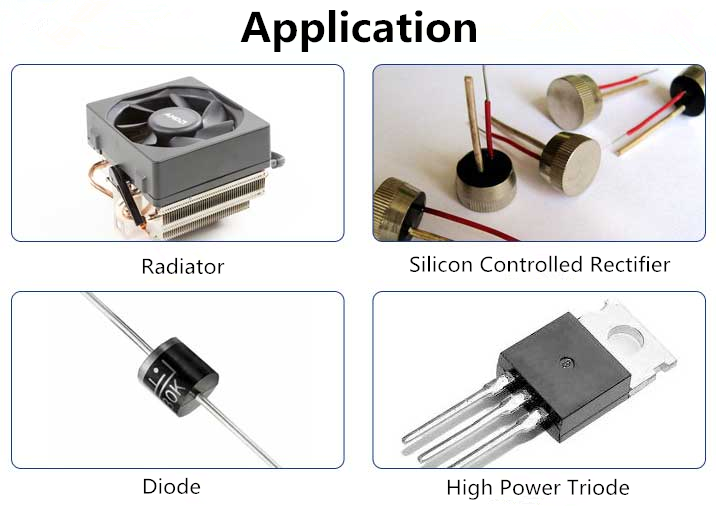

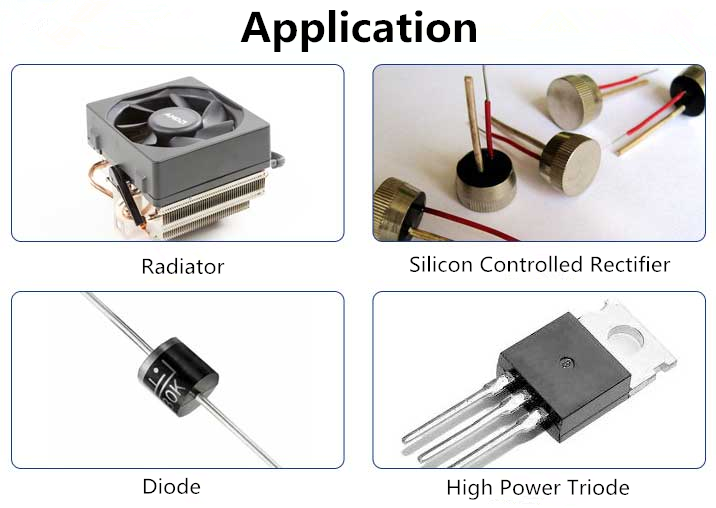

APPLICATION

Filling, bonding, and sealing in LED BULBS, LED lights

1. the gap between CPU and raditors, heat sink

2. the gap between thyristor control modules and radiator

3. filling of high-power electronics modules and radiators,etc.

TYPICAL PROPERTIES

|

Cured |

Property Name |

K-5204K |

|

|

Appearance |

white |

||

|

Viscosity ( cp ) |

thixotropic elastomer |

||

|

Density(g/c m 3 ) |

2.0~2.5 |

||

|

Initial Curing Time(25°c , min) |

≤30 |

||

|

Uncured |

Mechanical Properties |

Tensile Strength (Mpa) |

≥2.5 |

|

Elongation At Break (%) |

≥100 |

||

|

Shear Strength (Mpa) |

≥1.5 |

||

|

Hardness(shore A) |

50~65 |

||

|

Working Temp (°c ) |

-60~280 |

||

|

Electrical Properties |

Dielectric Strength(kv/mm) |

≥18 |

|

|

Permittivity (@60Hz) |

2.8 |

||

|

Volume Resistivity (Ω.cm) |

1×10 15 |

||

|

Coefficient of Thermal Conductivity(w/m.k) |

1.6 |

||

HOW TO USE

Preparation

Clean the un-bonded or uncoated surfaces by removing the rust, ash, and oil, etc.

Application

Pierce the opening with the tip of the cap. Fix the nozzle, and coat the clean surface evenly with the adhesives, then bond the two surfaces.

Curing Condition

a.The curing progress is from outer surface into inner surface.

b. The elastomer get cure with the depth of 2~4mm in 24 hours (at room temperature, 55% moisture). if the bonded parts is too deep (especially the parts not easy to contact with air) or the temperature is too low, the full curing time will be extend.

Advise user preparing enough time to let elastomer get full cure in order to keep the properties stably.

ATTENTION

1. After the application, screw its nozzle tightly and store in dry and cool place for next time using.

2. There may be some cured gel around the opening when you use it again, just remove the cured, and use the uncured.

PACKAGING 80g/ tube

STORAGE

Store in cool and dry place, the shelf life is 12 months (≤25°c )

Q: What information is needed for quotation quickly?

A: Please let us know your destination port, normal quantity, and payment term you like, then we can mail the quotation to you in 24 hours since receiving your i nquiry.

Q:How about the sample testing?

A:After confirming the adhesive code with customers, we can provide free sample ,only need to charge the shipping cost.

Q: How long can I expect to get the sample?

A: 3-5 days under normal conditions.

Q:What about the payment term?

A:Normally we accept the western union and paypal, the cargo can be ready for delivery in 7 days after we receive the payment.

Q:Are you a factory or trading company?

A: We are a factory.We are expert in adhesive and sealant since 1992, more than 25 years experience in production and sale.