- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

3.2*1.42*1.1m

-

Weight:

-

700 KG

-

Max enter width:

-

840mm

-

Max printing width:

-

650mm

-

Max printing length:

-

1200mm

-

Rubber letterpress thickness:

-

4-6mm

-

Printing roller diameter:

-

420mm

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SY

-

Voltage:

-

220v 380v

-

Dimensions(L*W*H):

-

3.2*1.42*1.1m

-

Weight:

-

700 KG

-

Max enter width:

-

840mm

-

Max printing width:

-

650mm

-

Max printing length:

-

1200mm

-

Rubber letterpress thickness:

-

4-6mm

-

Printing roller diameter:

-

420mm

Introduction of Flexo printing machine:

It is wide used for printing packing bag of chemicals, chemicals fertilizer, grain, feedstuff, cement, etc.

The control part of this machine adapts photoelectricity control, electromagnetic regulating, automatic imprinting on-off device, electronic automatic numerating. The power adapts stepless speed control in order to reach stable operation and wide speed control range. The machine is compact, easy to adjust and operate and maintain.

Features:

1.Advanced (plc)controller, Optomagnetic position locate & Pneumatic presser automatic clutch

2.Automatic Counting Linkage Work,1000-3500pcs/H

3.Adopt frequency controller ,more steady&power saving.

4.Advanced anilox roller ,automatic ink pump printing ink circulating system. Make Ink More Uniform &Plump

5.Plate print 360°designing,make printer more accurate.

It is wide used for printing packing bag of chemicals, chemicals fertilizer, grain, feedstuff, cement, etc.

The control part of this machine adapts photoelectricity control, electromagnetic regulating, automatic imprinting on-off device, electronic automatic numerating. The power adapts stepless speed control in order to reach stable operation and wide speed control range. The machine is compact, easy to adjust and operate and maintain.

Features:

1.Advanced (plc)controller, Optomagnetic position locate & Pneumatic presser automatic clutch

2.Automatic Counting Linkage Work,1000-3500pcs/H

3.Adopt frequency controller ,more steady&power saving.

4.Advanced anilox roller ,automatic ink pump printing ink circulating system. Make Ink More Uniform &Plump

5.Plate print 360°designing,make printer more accurate.

|

Model

|

SY-8902

|

SY-8903

|

SY-8904

|

SY-8905

|

|

Material width

|

150-780mm

|

150-780mm

|

150-780mm

|

150-780mm

|

|

printing width

|

1-650mm

|

1-650mm

|

1-650mm

|

1-650mm

|

|

printing length

|

300-1250mm

|

300-1250mm

|

300-1250mm

|

300-1250mm

|

|

Plate roller perimeter

|

1325mm

|

1325mm

|

1325mm

|

1325mm

|

|

Printing speed

|

1000-4200m/h

|

1000-4200m/h

|

1000-4200m/h

|

1000-4200m/h

|

|

Printing color

|

2 color

|

3 color

|

4 color

|

5 color

|

|

Machine power

|

1.5kw

|

2.2kw

|

3kw

|

4kw

|

|

Machine size

|

3.2*1.42*1.1m

|

3.86*1.42*1.1m

|

4.52*1.42*1.1m

|

5.18*1.42*1.1m

|

Feed Part

The roller setting of the bags printing machine is convenient for feeding. Smooth and high efficiency.

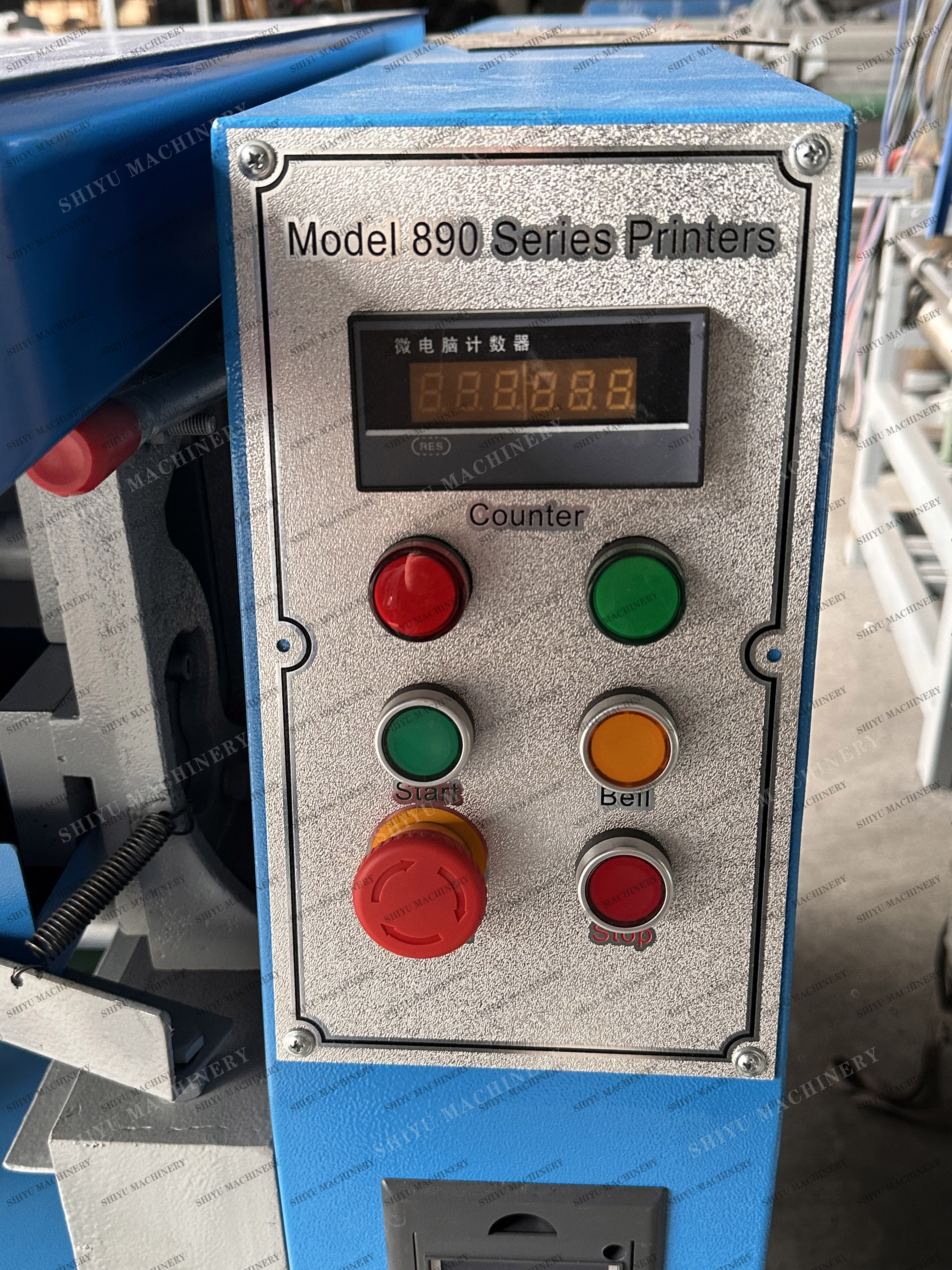

Control Part

The printer machine is easy to operate, and the printing quantity can be set according to the requirements.

Printing Part

Anilox roller is used to transfer ink, which makes the ink color uniform and enhances the printing smoothness

Electric system

Small size, high safety protection level, and the use is not limited by the site.

Hot Searches