- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

15000L

-

Weight (KG):

-

3000 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JCT

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

800*700*750mm to 2800*2000*2100mm

-

Power (kW):

-

75 kW

-

Applicable Industries:

-

Chemical industry

-

Machine material:

-

SS304 or SS316L

-

Paddle style:

-

Long ribbon blades

-

Mixing speed:

-

0 - 85rpm

-

Speed control:

-

Inverter for frequency control

-

Machine color:

-

Any color

-

Motor type:

-

Anti-explosion

-

Suitable materials:

-

Powder

-

Power(W):

-

2.2KW to 75KW

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Barrel Volume (L):

-

5000

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 120

-

Max. Loading Capacity:

-

15000L

-

Weight (KG):

-

3000 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JCT

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

800*700*750mm to 2800*2000*2100mm

-

Power (kW):

-

75 kW

-

Applicable Industries:

-

Chemical industry

-

Machine material:

-

SS304 or SS316L

-

Paddle style:

-

Long ribbon blades

-

Mixing speed:

-

0 - 85rpm

-

Speed control:

-

Inverter for frequency control

-

Machine color:

-

Any color

-

Motor type:

-

Anti-explosion

-

Suitable materials:

-

Powder

-

Power(W):

-

2.2KW to 75KW

-

After-sales Service Provided:

-

Video technical support

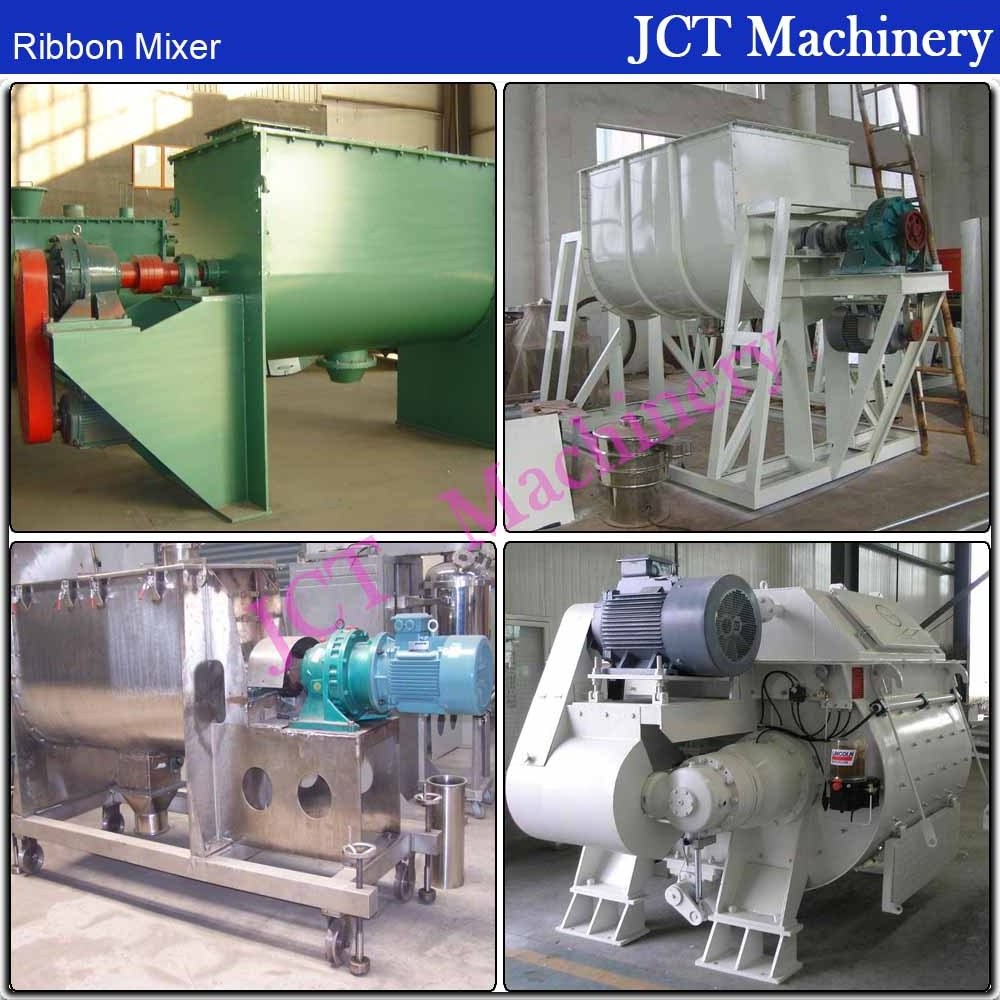

Foshan JCT acrylic powder for nails mixing machine

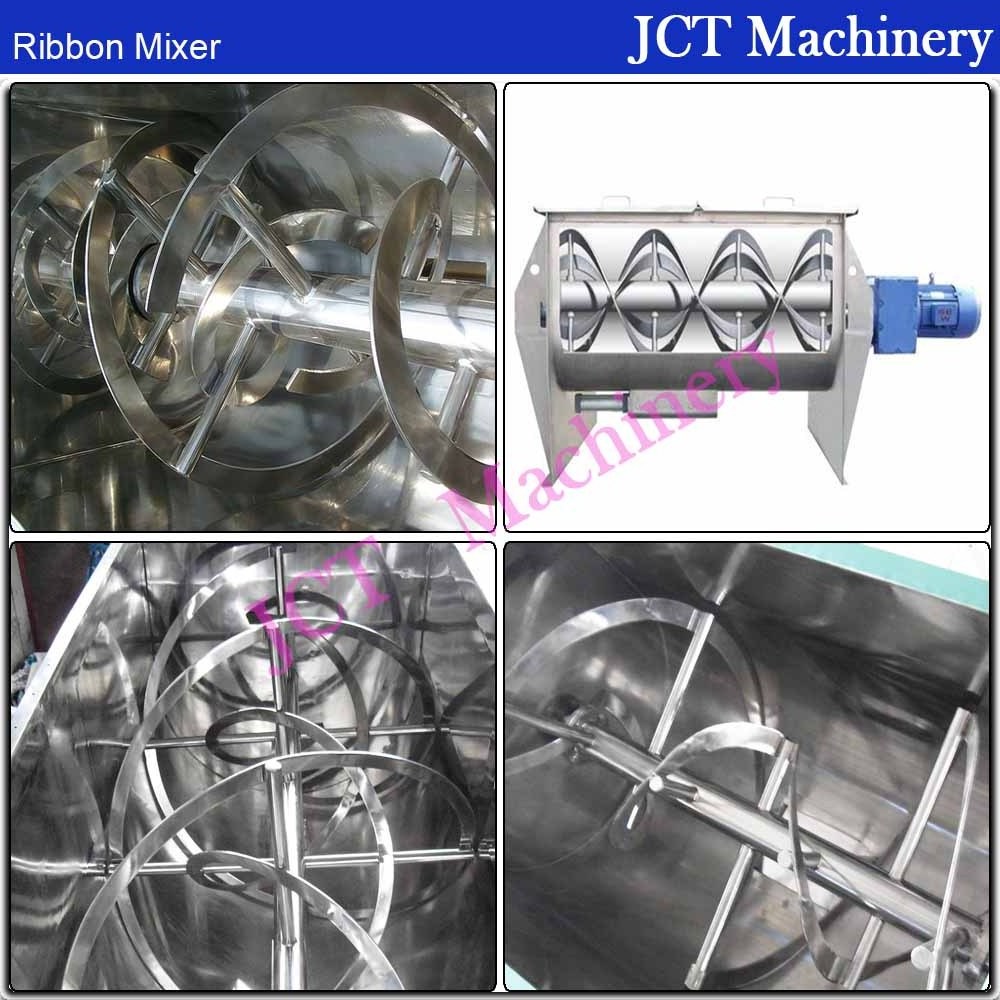

1. Working principle:

With the actuation of the directly link decelerator, the rotormoves in a fixed direction and, during its movement, the horizontal ribbon mixer pushed the material to move along with the axis and, on the other hand, throw the material to the front upper of the helicalribbon. The helical ribbon on the outside layer makes the material always moving towards the center of the barrel while the one on the inside layer makes the material moving towards two ends from the center, thus two cycled ways offlowing are formed with the material, making it fullmixed in the repeatedflowing circulation.

JCT horizontal ribbon mixer, powder mixer

2. Standard Features :

·Volume: 100-20000L

plastic auxiliary machine

·Ribbon agitator for center discharge plastic auxiliary machine

·Designed for normal temperature and normal atmospheric pressure tator for center discharge

·Feed Nozzle plastic auxiliary machine

·Manually operated or Pneumatic operated flap valve plastic auxiliary machine

·Packing SealSafety limit switch on cleanout door plastic auxiliary machine

·Carbon Steel, Stainless Steel 304, Stainless Steel 316L

·Continuous ribbon agitator, interrupted ribbon for higher density materialsInternal pressure

·Sanitary type construction

·Flap valve, butterfly valve, slide gate valve, ball valve

·Horsepower to suit higher density materials

·Explosion-proof motors

·Controls such as variable frequency drives, motor starters and operator stations are available

·Spray nozzles for liquid introductionJacket for heating or cooling

Standard form coning helix mixer machine have two churn helix, Practical applies to in according to equipment specification size can adopt single ( A long helix), Double ( Length each 1 incorrect states helix), Three ( Two short a long symmetrically disposal) Roots helix; Theoretically churns helix more many, Mixes effect more good.

Standard form equipment ordinary adopts plum blossom Chuang" Makes malposition valve ", Paste equal to tightness bottom this valve and long helix, Effective decreases mix dead angle, Drive form have manual gentle move can select; According to consumer need, Also can plus install reed valve, Ball valve, Starlike unloads glassware, Side comes out materical.

The finished powder mixer

The different blades of the ribbon mixer