Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v50hz

-

Dimension(L*W*H):

-

N/A

-

Weight:

-

5

-

Raw material:

-

PE PP Flake

-

Final product:

-

Dry Plastic Flakes

-

Output:

-

100--700kg/hr

-

Color:

-

Customer Choice

-

Pelletizing type:

-

Water Ring Pelletizing

-

Inverter:

-

ABB Brand

-

Control:

-

Electric Control

-

Capacity:

-

100kg/h-700kg/h

-

Power:

-

90kw

-

Certification:

-

CE ISO9001

Quick Details

-

Output (kg/h):

-

100 - 800 kg/h

-

Place of Origin:

-

China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380v50hz

-

Dimension(L*W*H):

-

N/A

-

Weight:

-

5

-

Raw material:

-

PE PP Flake

-

Final product:

-

Dry Plastic Flakes

-

Output:

-

100--700kg/hr

-

Color:

-

Customer Choice

-

Pelletizing type:

-

Water Ring Pelletizing

-

Inverter:

-

ABB Brand

-

Control:

-

Electric Control

-

Capacity:

-

100kg/h-700kg/h

-

Power:

-

90kw

-

Certification:

-

CE ISO9001

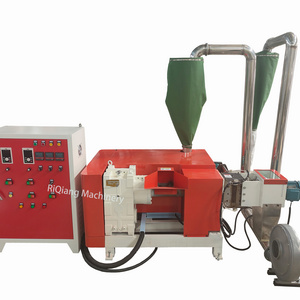

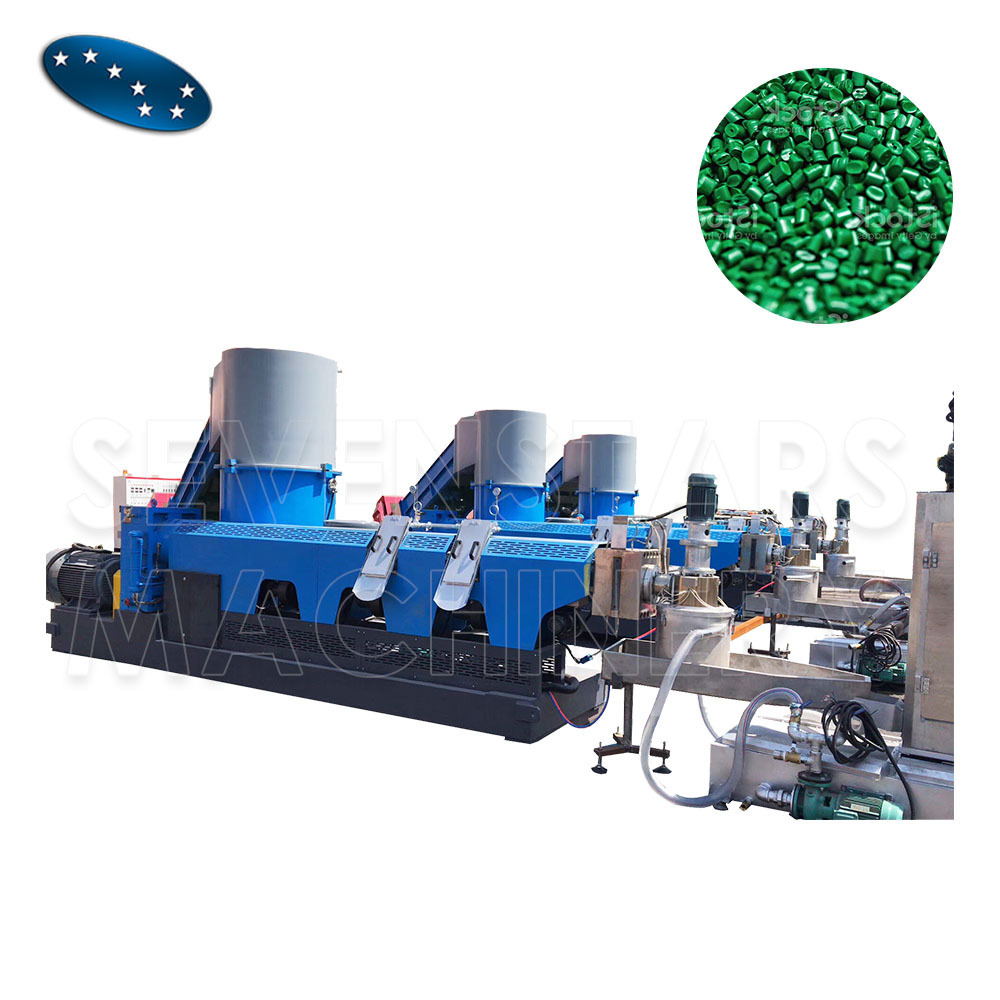

Advantages of this plastic pelletizing machine :

PE/PP recycling granulating machine is special equipment for the PE PP film recycling granulating, it equipped with compacting machine which could pre- compact the film into smaller granules, then easily feed into screw barrel of extruder, its efficiency is high and can improve production capacity and save labor cost.

It has two vacuum exhuasting mouth on extruder barrel which can fully vent the moisture in the material and hence the final granule quality will be very perfect.

At the end of screw barrel, it equipped with double post fast speed hydraulic non -stop screen changer which can effetively filt out the dirty in the plastic melt.

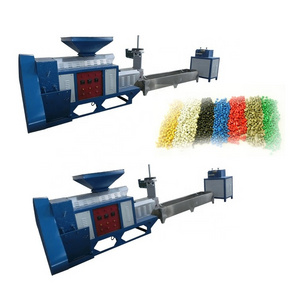

The pelletizing adopts water flush pelletizing which is easier to operate, and the shape and appearance of granule is good.

Specifications:

1.Client reference

2.Capacity:100-1000kgh

3.Pellet size: Diameter: 2.5 to 3mm

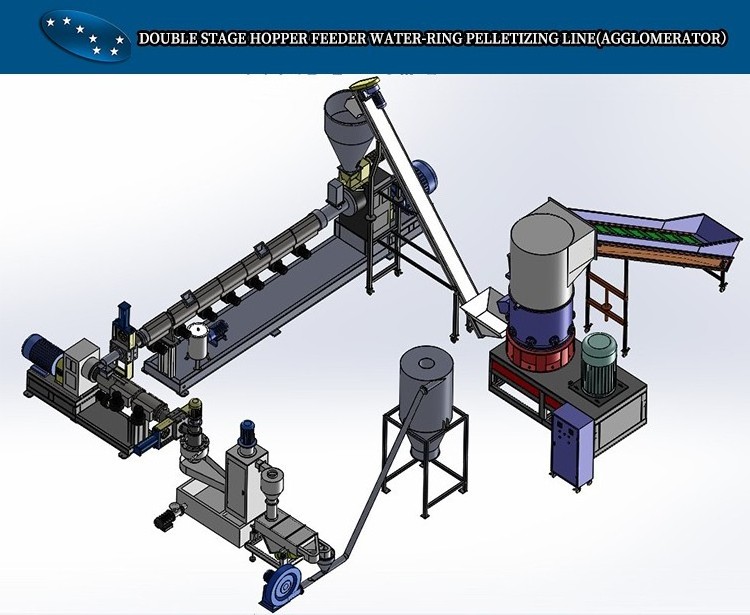

The process flow of PE PP pelletizing line as following:

Screw feeder →Side force feeder→ Extruding system1→High speed screen exchanging→Extruding system2 →High speed screen exchanger →water cooling bath→ air dryer→ pelletizer machine→ Silo

|

No

|

Parts of production line

|

Quantity

|

|

1

|

Belt conveyor

|

1set

|

|

|

metal detector

|

1set

|

|

2

|

PE film Compactor

|

1set

|

|

3

|

SJ Single screw Extruder

|

1set

|

|

4

|

High speed screen filter exchanger and extrusion die head

|

1set

|

|

5

|

SJ Single screw Extruder

|

1set

|

|

6

|

High speed screen filter exchanger and extrusion die head

|

1set

|

|

7

|

Water ring pelletizing machine

|

1set

|

|

8

|

Vertical dewater machine

|

1set

|

|

9

|

Vibrator sieve

|

1set

|

|

10

|

Air blower

|

1set

|

|

11

|

Silo

|

1set

|

|

12

|

Control cabinet

|

1set

|

The first stage extruder adopts exhaust type barrel screw, which can effectively de-gassing and eliminate the moisture and contamination;

And the second extruder usually adopts small L/D extruder, further plasticizing the material and filter contamination which can achieve stable extrusion.

|

Compactor feeding Pelletizing

|

|

|

|

|

||||

|

First stage

|

Main Motor

|

Second stage

|

Main Motor

|

Capacity

|

||||

|

85/36

|

55/37kw

|

100/10

|

22/30 kw

|

200kg/h

|

||||

|

100/36

|

90/55 kw

|

120/10

|

30/37 kw

|

300kg/h

|

||||

|

120/36

|

110/75 kw

|

130/10

|

37 kw

|

400kg/h

|

||||

|

130/34

|

132/90 kw

|

140/10

|

45 kw

|

500 kg/h

|

||||

|

140/34

|

132/110 kw

|

150/10

|

45 kw

|

600 kg/h

|

||||

|

160/34

|

160/110 kw

|

160/10

|

55 kw

|

600-700 kg/h

|

||||

This machine is used to extrude plastic cleaned by high temperature.The extrusion line can be consisted by such accessory machine:

main motor, the gear box, the distribution box, the barrel and screw, the dies,

water tank. Main Motor is mainly to supply the power. The Gear box transfers the motor to power.The distribution box enlarges the

strength of the power and realizes uniformity.

We use plug board type to change nets and keep machine working.The mould is made by 40Cr nitridation .The pressure sensor prompts to change the nets.There also can install a hydraulic equipment to change the nets more quickly.

We have 17000 square meters land and new modern workshop, we mainly development, design, manufacture and marketing plastic pelletizing machine, plastic recycling machine, pet bottle recycling machine, PVC pipe making machine, PE pipe making machine, PVC foam board production line, plastic granulator, plastic shredder, plastic pulverizer, Plastic agglomerator, plastic crusher and so on. After fifteen years of development, we grown up to a middle scale company in China plastic industry.

As one of the reliable supplier in China, We have keeping improved our management and technology level. Up to now, we have earned good reputation in domestic and abroad market. And our products have been exported to many countries, like Mexico, America, Argentina, Chile, Brazil, Russia and so on.

Quality and honest is our foundation, customer satisfactory is our job, to get “Win-Win” is our main target. We always focus on improving our quality. And we have built up a professional after-sale services team with rich-experienced in machine commissioning and installation. We believe our quality and service will bring success to each customer.

Welcome final users and distributors from all over the world contact with us and create success.

With your support and our effort, we deeply believe that the tomorrow of Sevenstars will be much better.