- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Chengjinlai

-

Voltage:

-

380V-415V-440V-460V

-

Weight:

-

2200 KG

-

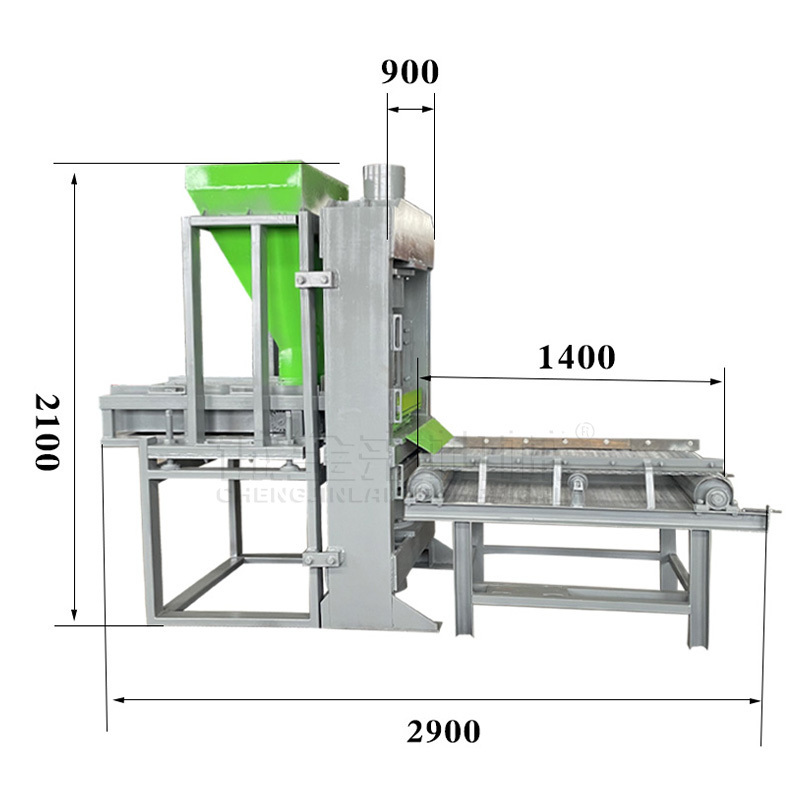

Dimension(L*W*H):

-

2.9 x1.8 x2.2m

-

Raw material:

-

Charcoal Powder

-

Name:

-

Charcoal Briquette Making Machine

-

Usage:

-

Making Charcoal Coal Briquette

-

Color:

-

Customers' Requirement

-

Briquette Shape:

-

Hexagonal Hollow Cylindrical Cubic

-

Package:

-

Wooden Case

-

Pressure type:

-

Hydraulic Pressure

-

Final Briquette Size:

-

30-70mm

-

Mold:

-

Custom Designed

-

Phase:

-

Three

Quick Details

-

Warranty:

-

5 years

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

Automatic charcoal briquette making machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Chengjinlai

-

Voltage:

-

380V-415V-440V-460V

-

Weight:

-

2200 KG

-

Dimension(L*W*H):

-

2.9 x1.8 x2.2m

-

Raw material:

-

Charcoal Powder

-

Name:

-

Charcoal Briquette Making Machine

-

Usage:

-

Making Charcoal Coal Briquette

-

Color:

-

Customers' Requirement

-

Briquette Shape:

-

Hexagonal Hollow Cylindrical Cubic

-

Package:

-

Wooden Case

-

Pressure type:

-

Hydraulic Pressure

-

Final Briquette Size:

-

30-70mm

-

Mold:

-

Custom Designed

-

Phase:

-

Three

Charcoal Briquette Making Machine For Both Bbq And Shisha

1-Product Desription for Charcoal Briquette Making Machine

Charcoal Briquette Making Machine can be used to compress the charcoal powder material into shisha briquettes , it is now the urgently needed equipment in the world.

Our company with 30 years of hookah making machine research and design experience, adopts low cost high efficiency manufacturing rules, greatly benefited the Arab shisha charcoal equipment.

2-Mold And Prodcts for

Charcoal Briquette Making Machine

Mould shape: cubic, round briquettes, cylinder, hexagonal, etc.

Mould size: 22*22m, 23*23mm, 25*25mm, 30mm, 33mm, 35mm, etc.

Mould material: professional mould steel material, stainless steel material, etc.

Shisha charcoal sample shape and size both can be customized according to customer requirements, for example special shape,special logo, etc.

3 - Machine Display For Charcoal Briquette Making Machine

Hydraulic pump station

Owing to shisha charcoal briquette making machine use hydraulic type, so it have hydraulic pressure station. Pressure can reach 100-200 tons. And have pressure gage on the hydraulic station. Also there have pump outside, can ensure the safety, with cooling system.

PLC system

The PLC system enable hookah making machine work automatically or manually, the pressure and pressing times can also be adjusted.

Mould

Mould shape can be cubic, round, hexagonal, finger shape or customized. Also you can use this machine with different mould for different shape of briquette.

Hydraulic cyli nder

This part is used to offer pressure, so that final briquette will have high density and very hardness.

4-Main Parameter For Charcoal Briquette Making Machine

| Model | LT-22-BBQ mold | LT-36-Shisha mold |

| Capacity | 1000-1200kg/h | 300-400kg/h |

| Motor | 15+2.2+0.75kw | 15+2.2+0.75kw |

| Raw material | charcoal powder, coal powder or other model charcoal powder | |

|

Shisha mold /BBQ mold |

Diameter for shisha :22mm,23mm,24mm,25mm,26mm. Diameter for bbq : 45mm,50mm,55mm |

|

| Pressure | 100 ton | 40 ton |

5-Packaging and Shipping for Charcoal Briquette Making Machine

Packing

* Machine will be wrapped up with plastic film first (including the motor).

* The plastic film bag wrapped machine, according to the size and weight to make wooden or iron box, put machine in and fixed the box after loading. (The box material can be made as your requirements)

* The Charcoal Briquette Making Machine parts need to be put in a fixed container, should be fixed well, lest collision and wear, or lost.

6-Product Line for Charcoal Briquette Making Machine

We often design different project for customer, it is according to customer requirement, like various material, capacity, invest, we all can according to these conditions to design, now you can see this roughly production line, exact production line is according to your requirement.

1). Make your coconut shell become charcoal by carbonizing.

2). Then crush the coconut shell charcoal into powder less than 2mm.

3). Owing to charcoal powder have no stickness, so you need to add some binder into it and mix.

4). Use electric charcoal briquette making machine to press mixed charcoal into different shape and sizes.

5). The last but not least is drying, put final product dry by dryer, then finished.