- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

8*2*2.5M

-

Power (kW):

-

90 110 132

-

Weight:

-

10

-

Screw Speed (rpm):

-

1 - 130 rpm

-

Material:

-

PP/PE

-

Plastic Type:

-

plastic film granulating machine

-

Material Processed:

-

plastic film pellet machine

-

pelletizer line machine:

-

granulating granulator recycled ps scrap pelletizer price

-

pp pe film recycling production machine:

-

PE, PP film recycling, pelletizing line

-

pp pe film granulator:

-

pp pe pelletizer pellet making machine

-

This granulating machine is for:

-

process waste material such as PE

-

plastic recycling machine:

-

plastic film recycling machine

-

plastic bags recycling machine:

-

pe recycling machine

-

Marketing Type:

-

New Product 2020

Quick Details

-

Output (kg/h):

-

100 - 1000 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HorseRider

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

8*2*2.5M

-

Power (kW):

-

90 110 132

-

Weight:

-

10

-

Screw Speed (rpm):

-

1 - 130 rpm

-

Material:

-

PP/PE

-

Plastic Type:

-

plastic film granulating machine

-

Material Processed:

-

plastic film pellet machine

-

pelletizer line machine:

-

granulating granulator recycled ps scrap pelletizer price

-

pp pe film recycling production machine:

-

PE, PP film recycling, pelletizing line

-

pp pe film granulator:

-

pp pe pelletizer pellet making machine

-

This granulating machine is for:

-

process waste material such as PE

-

plastic recycling machine:

-

plastic film recycling machine

-

plastic bags recycling machine:

-

pe recycling machine

-

Marketing Type:

-

New Product 2020

Product Description

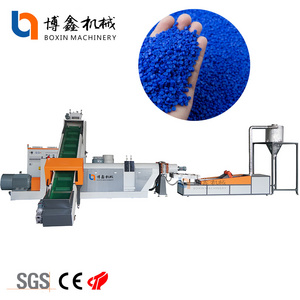

Plastic Recycling Pelletizing

HorseRider Machinery

Side feeding water ring granulation

Material side feeding water ring granulation technology can realize precise control of plastic particle size, dispersion and heat load, improve product quality and performance, and is suitable for a wide range of plastic processing and application fields

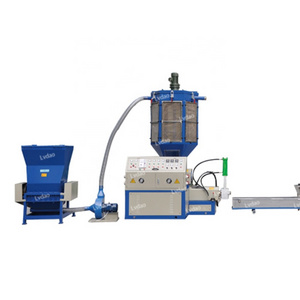

two-stage granulation

Plastic two-stage granulation technology has the advantages of adjustable particle size, high-quality particles, good particle uniformity, wide applicability, high efficiency and recyclability, making it a commonly used preparation technology in the field of plastic processing and recycling.

Compactor granulation

Plastic compactor granulation has important applications in plastic recycling, granule preparation, additive preparation, composite material preparation, coating and pigment preparation, etc., which helps to improve the utilization efficiency and product quality of plastics

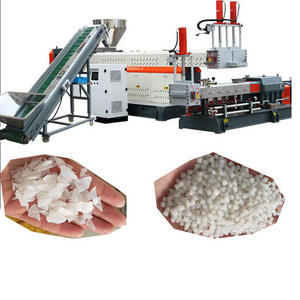

Plastic water ring granulation technology has the advantages of uniform dispersion, control of particle size and shape, high-quality particles, suitable for heat-sensitive plastics, and improved solubility and processability. It plays an important role in the preparation and processing of plastics, and is widely used in the fields of preparation and modification of plastic particles

Plastic strand granulation technology has the advantages of uniform particle distribution, adjustable particle size, optimized plastic properties, suitable for heat-sensitive plastics, reduced particle pollution and high production efficiency.

PP (polypropylene) and PE (polyethylene) plastic granulator is a kind of equipment used to recycle and process waste plastic into new plastic granules. They have the following applications and features:

application:

Recycling waste plastics: PP PE plastic granulator can process various types of waste plastics such as polyethylene, polypropylene, polyvinyl chloride, etc. into pellets, which is helpful for the recycling of waste plastics.

Production of new materials: PP PE plastic granulator can use the processed granules to produce new plastic products, such as plastic film, plastic bags, plastic bottles, etc.

Reduce production costs: PP PE plastic granulator can recycle waste plastics, thereby reducing production costs and improving production efficiency.

Features:

High efficiency and energy saving: PP PE plastic granulator adopts energy-saving design and has high-efficiency processing capacity, which can greatly reduce energy consumption and reduce production costs.

Good adjustability: The processing parameters of the PP PE plastic granulator can be adjusted according to different types of plastic granules to obtain the best processing effect.

Easy to operate: PP PE plastic granulator is easy to operate and easy to use without professional skills.

Uniform particle size: The plastic particles processed by the PP PE plastic granulator have uniform particle size and stable quality, which can meet different production needs.

Specification

|

Model

|

Screw Diameter

|

Screw L/D

|

Second Screw L/D

|

Main Motor Power

|

Capacity

|

|

SJ85

|

85mm

|

28-33:1

|

10-12:1

|

55KW

|

150-200kg/hr

|

|

SJ100

|

100mm

|

28-33:1

|

10-12:1

|

75KW

|

200-300kg/hr

|

|

SJ130

|

130mm

|

28-33:1

|

10-12:1

|

90KW

|

300-400kg/hr

|

|

SJ150

|

150mm

|

28-33:1

|

10-12:1

|

110KW

|

400-500kg/hr

|

|

SJ160

|

160mm

|

28-33:1

|

10-12:1

|

132KW

|

500-600kg/hr

|

|

SJ180

|

180mm

|

28-33:1

|

10-12:1

|

160KW

|

600-800kg/hr

|

|

SJ200

|

200mm

|

28-33:1

|

10-12:1

|

200KW

|

800-1000kg/hr

|

Details Images

Hot Searches