ustomize the packaging according to your requirements

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

induction heating machine

-

Type:

-

digital circuit

-

Power:

-

50kw

-

Frequency:

-

50hz

-

Certification:

-

CE ISO

-

After-sales Service Provided:

-

Free spare parts

-

After Warranty Service:

-

Spare parts

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KECHUANG

-

Weight (KG):

-

150

-

Application:

-

induction heating machine

-

Type:

-

digital circuit

-

Power:

-

50kw

-

Frequency:

-

50hz

-

Certification:

-

CE ISO

-

After-sales Service Provided:

-

Free spare parts

-

After Warranty Service:

-

Spare parts

Products Description

|

Model

|

XZC-60SCZ

|

|

Input voltage

|

380V ±10%

|

|

incoming current

|

≤130A

|

|

frequency

|

50-60Hz

|

|

Inverter frequency

|

50-300kHz

|

|

output power

|

≤60kw

|

|

control precision

|

1‰

|

|

Power output range

|

5%-100%

|

|

Inverter power factor

|

≥0.96

|

|

control mode

|

Constant current, constant power, constant temperature

|

|

Cooling water pressure

|

0.1-0.3MPa

|

|

environment temperature

|

5℃-45℃

|

Main characteristic

The induction heating technique applied to crystal growth has a series of characteristics and advantages over the resistance wire or graphite bulk heating method: Direct heating crucible, high power density, easier to obtain High temperature;Induction heating without electric connection point, good insulation conditions, uniform temperature field;Fast starting, small thermal inertia, high system response speed;High efficiency and energy saving;No wearing parts, lower operating cost.Induction heating for crystal

growth can be applied to: silicon carbide, sapphire, laser crystal and other crystals.Crucible types can be: graphite crucible, gold crucible, tungsten and molybdenum crucible, platinum crucible and so on.Crystal growth has very strict requirements on the temperature field environment: stable temperature and uniform temperature field, so the output power precision of the power supply is very high requirements, many power supplies can not meet the accuracy requirements, often with the help of external controllers

such as continental meters for high precision closed-loop control, which not only increases the cost, but also due to the accuracy and stability of the power supply, the actual effect is not ideal.Kechuang pioneered a whole new control method of induction heating for crystal growth, high-precision induction heating power supply is specially designed and developed for crystal growth applications. After

growth can be applied to: silicon carbide, sapphire, laser crystal and other crystals.Crucible types can be: graphite crucible, gold crucible, tungsten and molybdenum crucible, platinum crucible and so on.Crystal growth has very strict requirements on the temperature field environment: stable temperature and uniform temperature field, so the output power precision of the power supply is very high requirements, many power supplies can not meet the accuracy requirements, often with the help of external controllers

such as continental meters for high precision closed-loop control, which not only increases the cost, but also due to the accuracy and stability of the power supply, the actual effect is not ideal.Kechuang pioneered a whole new control method of induction heating for crystal growth, high-precision induction heating power supply is specially designed and developed for crystal growth applications. After

development and continuous improvement, the high-precision induction heating power supply has made a

qualitative improvement and become a very cost-effective crystal growth power supply in the global

qualitative improvement and become a very cost-effective crystal growth power supply in the global

industry

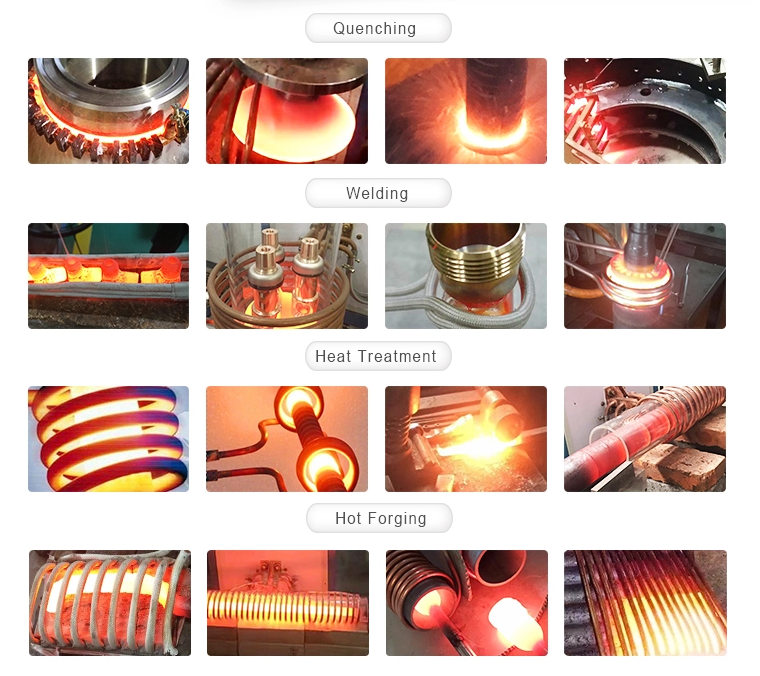

Product Application

1.

Heat treatment for various hardware and tools, such as plier, wrench, hammer, ax,screwing tools.

2.·Heat treatment for various automobile and motorcycle fittings, such as crankshaft,connecting rod, piston pin, chain wheel, aluminum wheel, valve,rock arm shaft,semi drive shaft, small shaft and fork.

3.Heat treatment for various electric tools, such as gear and axes.

4.Heat treatment for machine tools,such as lathe deck and guide rail. 5. Hardening for various hardware metal parts and machined parts, such as shaft,gear chain wheel, cam,chuck and clamp.

6. Heating for hardware molds, such as small-size mold, mold accessory and inner hole of mold.

7. Annealing of various stainless steel products, such as stainless steel basin,annealed and extruded can, annealed folded edge, annealed sink, stainless steel tube, tableware and cup.

·8. Forging of various other metal work pieces, such as round steel, sheet/plate, pipe and others.

Why choose us

Our company

Company profile

Zhengzhou kechuang Electronics Co.,Ltd was established in 31th,August 2001.Kechuang has been developed hundreds of products which has been widely spread and enjoyed by both national and international market since 2001. In 2016,in order to meet the high-end users' demand both in domestic and overseas.We produced much higher performance,higher percision and higher cost-effective intelligent IGBT power supply. Kechuang always has always regard "more energy-saving","more reliable" as the product development direction.Completing the products automatic,intelligent and robotic functions , which leads in the first of national induction heating technology.All of our products and technologies can provide

.

Exhibition

Certifications

Packing & Delivery

delicately packed

Hot forging machine welding equipment annealing furnace induction heater packed in wooden.

We can also

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Engineers available to service machinery overseas.

Hot Searches