- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CM-902

-

Brand Name:

-

OEM

-

Max Machining Capability:

-

46000 X 8000 X 7000 mm

-

Multi Hole Drilling Capability:

-

13000 X 6000 mm

-

Material:

-

Steel, Customers' Requirement

-

Equipment:

-

Turning & Milling Machine

-

Turning Capabilities:

-

Dia:5000 mm

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, Other

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

CM-902

-

Brand Name:

-

OEM

-

Max Machining Capability:

-

46000 X 8000 X 7000 mm

-

Multi Hole Drilling Capability:

-

13000 X 6000 mm

-

Material:

-

Steel, Customers' Requirement

-

Equipment:

-

Turning & Milling Machine

-

Turning Capabilities:

-

Dia:5000 mm

Products Description

Hi There,

Welcome to our company! We provide custom metalworking services with METAL CASTING , CNC MACHINING and METAL FABRICATION , all products are customized. We are very pleased to provide a quotation!

To get a quickly quote, please provide the following information.

* Detailed drawings

Material, Dimensions, Tolerances, Surface Finishing, etc. should be enclosed together.

* Quantity per order

It’s essential.

* 3D file

It’s not essential, but it can speed up our quotation as well as the accuracy.

Welcome to our company! We provide custom metalworking services with METAL CASTING , CNC MACHINING and METAL FABRICATION , all products are customized. We are very pleased to provide a quotation!

To get a quickly quote, please provide the following information.

* Detailed drawings

Material, Dimensions, Tolerances, Surface Finishing, etc. should be enclosed together.

* Quantity per order

It’s essential.

* 3D file

It’s not essential, but it can speed up our quotation as well as the accuracy.

Contact Us For A Quote!

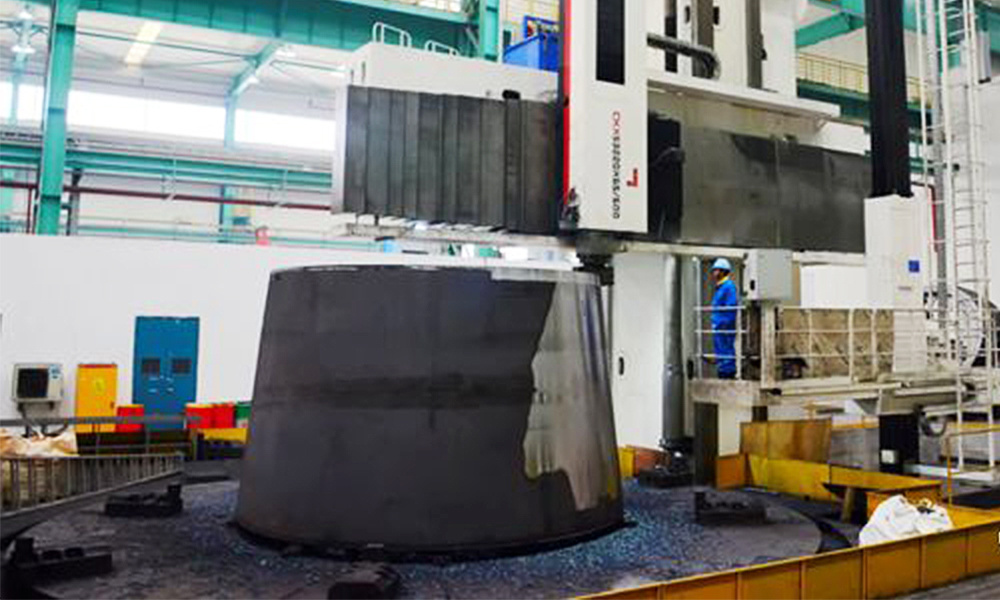

Precision Machining of Secondary Planetary Carrier of 110 Ton Mining Car.

The processing technology is rough machining, semi-finishing, and then finishing.

Customers put forward strict requirements on the geometric tolerance, positioning accuracy, dimensional accuracy and surface roughness of the whole set of products.

More Cases

marine detection equipment parts

bridge rotary locking device

vacuum dewar vessel parts

part of a split mill

About Us

Openex Mechanical Technology Ltd.

Openex Mechanical Technology Ltd., based in Xiamen, China, has been in the business since 2003. We are a unique companys that have the capabilities to provide a full range of metalworking products and services to customers worldwide. We produce metal parts and assemblies involving single or combinative processes such as machining, metal fabrication, casting, forging, etc.

Our Partener

We are able to provide a wide range of custom etalworking, especially high precision fabrication and CNC machining from the medium parts to large complex assemblies.

More than 30 industrial giants listed in Fortune global 500 are our clients. Some of the customers have cooperated with us formore than 10 years.

More than 30 industrial giants listed in Fortune global 500 are our clients. Some of the customers have cooperated with us formore than 10 years.

Our Certifications

We understand the importance of meticulous quality management and we have already passed certificates as follow.

>Lloyds register

of shipping (LR) certification

>ISO9001/14001/OHSAS18001 certification

>API certification

>DET NORSKE VERITAS (DNV) certification

>ASME U/U2/PRT certification

of shipping (LR) certification

>ISO9001/14001/OHSAS18001 certification

>API certification

>DET NORSKE VERITAS (DNV) certification

>ASME U/U2/PRT certification

Our Experience

Our products are applied to a variety of industries serving a wide range of purposes, such as Machinery, Rail Transit, Power/Energy, Boat/Bridge, Infrastructure, Oil/gas, Aerospace, Mining, Engineering Machinery, Chemical Equipment etc.

Our Capabilities

|

8 Process Platforms

|

|

|

|

|||

|

Painting

|

Heat Treatment

|

Assembly

|

||||

Custom Metalworking Capability

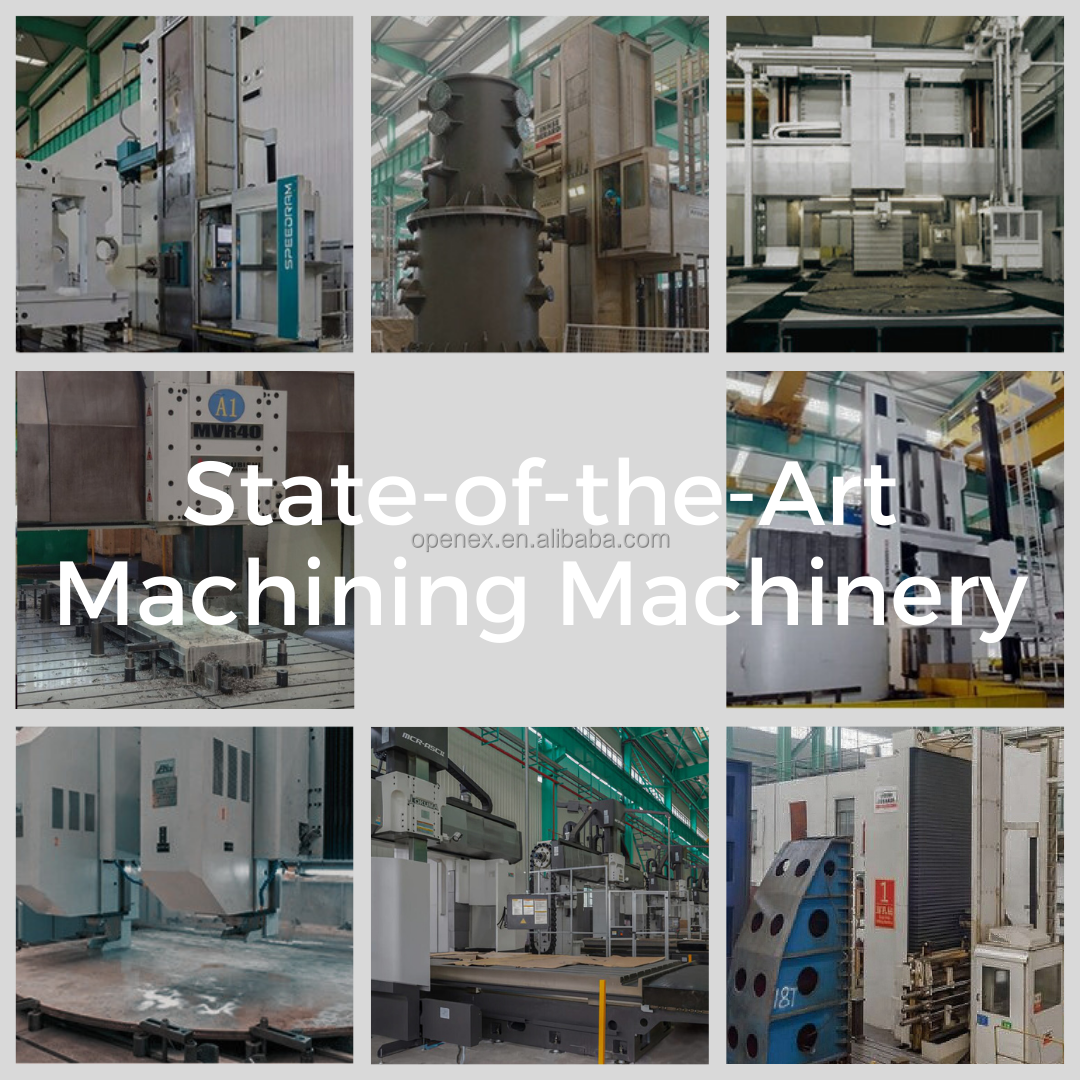

We have world-class metalworking equipment to provide world-class machining services. Eg. Our Schiess VMG6 gantry milling CNC can machine large parts up to 40m X 8m X 7m under 450t, also equipped with high precision CMM and laser tracking measuring machine together with robotic tool changers to speed all machining process.

Contact us

to see the details of our equipment list.

Quality Assurance

Inspection Equipment

We have equipped our factory with the best inspection tools, like ultrasonic tester (UT) for welding, Leica AT901-LR laser tracker, and different types of CMM test machines, which make our quality guaranteed.

Quality Management System (QMS)

In addition to advanced testing equipment and means, we also implement a strict quality management system (ISO9001:2005) in the production process. Implementing a QMS can provide significant benefits to our customers, including improved product and service quality, increased customer satisfaction, and competitive pricing.

Packing & Shipping

Packing & Shipping

There are many ways of packaging and transportation for customers to choose, and we can also recommend the most economical and reasonable way.

Moreover, we have rich experience in maximizing container loading by applying computer simulation technology, which enables us to reduce freight up to 20% and improving packing to minimize potential damage in transportation.

Recommend Services

Should any of the items be of interest to you, please contact me via eva@openex.com.cn.

Hot Searches