- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.27 or customized

-

Cooling Mode:

-

Water Cooling

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Anytester

-

Voltage:

-

1200

-

Dimension(L*W*H):

-

1000*430*1150

-

Year:

-

2021

-

Power (kW):

-

12

-

Weight (KG):

-

650 KG

-

Capacity:

-

0.1~1.8kg

-

Roll size:

-

110*350mm or customized

-

Roll material:

-

High hardness SKD chromium molybdenum alloy

-

Temperature range:

-

RT-300℃

-

Temperature deviation:

-

±3℃

-

Heating time:

-

R.T to 200℃ in 25min

-

Heating mode:

-

Oil

-

Nip gap:

-

0.1~6mm adjustable

-

Speed of front roll:

-

24rpm or 0~35RPM adjustable or customized

-

Friction ratio:

-

1:1.35 or customized

Quick Details

-

Diameter of Roll(mm):

-

150 mm

-

Rotation Speed of Front Roll(rpm):

-

1 - 35 rpm

-

Length of Roll(mm):

-

320 mm

-

Roll Ratio(Front/Back):

-

1:1.27 or customized

-

Cooling Mode:

-

Water Cooling

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Anytester

-

Voltage:

-

1200

-

Dimension(L*W*H):

-

1000*430*1150

-

Year:

-

2021

-

Power (kW):

-

12

-

Weight (KG):

-

650 KG

-

Capacity:

-

0.1~1.8kg

-

Roll size:

-

110*350mm or customized

-

Roll material:

-

High hardness SKD chromium molybdenum alloy

-

Temperature range:

-

RT-300℃

-

Temperature deviation:

-

±3℃

-

Heating time:

-

R.T to 200℃ in 25min

-

Heating mode:

-

Oil

-

Nip gap:

-

0.1~6mm adjustable

-

Speed of front roll:

-

24rpm or 0~35RPM adjustable or customized

-

Friction ratio:

-

1:1.35 or customized

Product Description

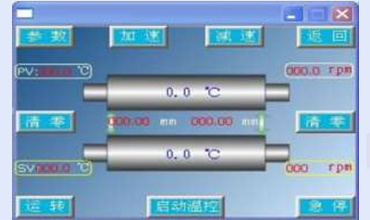

AT380 Series Two Roll Mill

is used to mix, scatter and plasticize materials for color matching, quality control and research. It is suitable for masterbatch, PVC, plastic, pigment dispersion on plastics.

Specification

|

Model

|

AT380-4-A

|

AT380-4-B

|

AT380-4-C

|

AT380-4-D

|

|||

|

Capacity

|

0.1~1.8kg

|

|

|

|

|||

|

Roll size

|

Ø110×350mm or customized

|

|

|

|

|||

|

Roll material

|

High hardness SKD chromium molybdenum alloy

Roll surface: HRC 60 mirror chrome plated

|

|

|

|

|||

|

Temperature range

|

RT-300℃

|

|

R.T

|

RT-300℃

|

|||

|

Temperature deviation

|

±3℃

|

|

/

|

±3℃

|

|||

|

Heating time

|

R.T to 200℃ in 25min

|

|

/

|

R.T~ 200℃ in 25min

|

|||

|

Heating mode

|

Electric

|

Oil

|

/

|

Electric

|

|||

|

Cooling mode

|

/

|

/

|

Water

|

|

|||

|

Nip gap

|

0.1~6mm adjustable

|

|

|

|

|||

|

Speed of front roll

|

24rpm or 0~35RPM adjustable or customized

|

|

|

|

|||

|

Friction ratio

|

1:1.35 or customized

|

|

|

|

|||

|

Roll temperature control

|

independent adjustment of two rolls

|

|

|

|

|||

|

Motor Power

|

1.5KW

|

|

|

|

|||

|

Power supply

|

3phase AC380V 50Hz, 22A

|

|

|

|

|||

|

Dimensions (mm)

|

1100×550×1380

|

|

|

|

|||

|

Weight (kg)

|

360

|

|

|

|

|||

Details & Features

★ Two heating modes optional: electric heating or oil heating, with or without water cooling

★ Hard chrome plated rolls with mirror polished surface, anti-corrosive, high temperature resistant, fast thermal conduction.

★ The roll size can be customized according to requirement.

★ Digital display roll gap , 0.05~8mm adjustable.

★ With multiple emergency stop device, more safe.

1.Emergency stop pull rod on the top of machine. Pull the rod, the two rolls will stop immediately.

2.Reversal stop switch on the front door. Kick the switch with knee, the two rolls will rotate reversely and stop after a few seconds. This time can be set by the user.

3.With emergency stop button on the controller.

4.Available with safety hood to prevent the operator hands stretch into the two rolls (optional).

5.Pneumatic emergency stop function to separate rolls to avoid secondary damage (optional)

★ The speed of two rolls can be fixed with a constant friction ratio, or be adjustable with a constant friction ratio, or be

adjustable with variable friction ratio.

adjustable with variable friction ratio.

Our Company

Onsite service

Installation and training service is available

Testing service

Free sample testing before order is available

Lead time

15 working days lead time for most product

Packing & Delivery

|

Packaging

AT380 Lab with Heating and Cooling Plastic Rubber product Two Roll Mixing Mill Machine

|

|

|

|

Packaging Details

|

1. The equipment is covered with film is protect it from water vapour during the trip.

2. The box is filled with foam to protect the equipment from impact.

3. Exported wooden box made from plywood, don't need fumigated.

|

|

Payment

|

Payment Term

AT380 Lab with Heating and Cooling Plastic Rubber product Two Roll Mixing Mill Machine

|

T/T

|

EXW

|

30% T/T in advance, paid the balance before shipment

|

||

|

|

|

FOB

|

|

||

|

|

|

CFR(C&F)

|

|

||

|

|

|

CIF

|

|

||

|

|

L/C

|

L/C amount above 50,000 usd, we can accept L/C at sight

|

|

||

|

|

West Union

|

Amount lower than 5000usd

|

|

||

|

|

West Union

|

|

|

||

|

Delivery Time

|

7~10days after receiving payment for one container

|

|

|

||

Contacting Us

Hot Searches