- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3 phase 380V 50HZ /220v60Hz

-

Dimension(L*W*H):

-

30x6x3m

-

Power (kW):

-

80

-

Weight (KG):

-

15000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

sheet thickness:

-

0.8--5mm

-

forming machine efficiency:

-

3-5s/Die

-

Raw material:

-

GPPS/PS/ hips / talc powder

-

Usage:

-

to make PS foam take away food container

-

Color:

-

Customized

-

forming machine:

-

fully automatic with robot arms

-

the complete line include three machine:

-

sheet extruder+forming machine +recycling machine

-

Ellie's WhatsApp:

-

008613780912769

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Haiyuan

-

Machine Type:

-

foaming machine

-

Voltage:

-

3 phase 380V 50HZ /220v60Hz

-

Dimension(L*W*H):

-

30x6x3m

-

Power (kW):

-

80

-

Weight (KG):

-

15000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

sheet thickness:

-

0.8--5mm

-

forming machine efficiency:

-

3-5s/Die

-

Raw material:

-

GPPS/PS/ hips / talc powder

-

Usage:

-

to make PS foam take away food container

-

Color:

-

Customized

-

forming machine:

-

fully automatic with robot arms

-

the complete line include three machine:

-

sheet extruder+forming machine +recycling machine

-

Ellie's WhatsApp:

-

008613780912769

-

Marketing Type:

-

Hot Product 2021

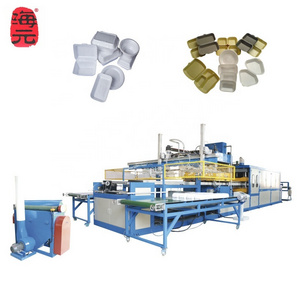

competitive price PS foam extruder machine for making take away food box container plate

♦The whole production line includes the following 4 parts♦

PS foam sheet extrusion machine

fully automatic forming machine

crusher

recycling machine

1.PS foam sheet extrusion machine

PS foam sheet extrusion machine adopts Gentian type double-stage series high foam technology.The raw material is general polystyrene granule.This equipment adopts high speed non-stop hydraulic filter changer and PLC controller, advantage as advanced structure, stable performance,easy operation and high quality. It adopts Gentian type double-stage series high foam technology. The raw material is general polystyrene granule (GPPS). In the extruding process, foam agent (such as butane gas or LPG) is injected at high pressure. After extruding , foaming, cooling, shaping and hauling off, it is winding to finished ps foam sheet rolls. It is easy to operate and of high efficiency.

It features reliable stability ,large forming area ,fast speed highly automation and economic on manpower .

polystyrene foam food container box making machine use PS(polystyrene) granule as main material.

Finished sheet rolls :

PS foam sheet extrusion machine PARAMETER :

2.Fully automatic vacuum forming machine

This machine integrate forming,cutting at the same time, also the foam products could come out automatically. It adopts PLC controller and touch screen to control the working programmer. It is easy to operate and features high degree of automation.

fully automatic forming machine PARAMETER :

Finished products :

3.Crusher

This machine mainly used to rus h the waste materials

into little pieces.

4 .Recycling Machine

This machine is mainly used to recycle the crushing pieces into ps granules.

It is the ideal equipment to recycle the waste mateials.

This equipment features compact structure and easy operation.The scrap pieces can be directly used

to make granulation without comminuting.At present ,

it is the energy-saving equipment to let the material circulation and reduce the waste.

Haiyuan Machinery with CE and ISO certifications

Packaging and Shipping

Shipping: FOB Qingdao.

Packaging: standard package for export.

the complete production line need 3X40HQ.

please send hi to Ellie's WhatsApp :

008613780912769