- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v, 220v/380v

-

Power:

-

3kw

-

Dimension(L*W*H):

-

can choose

-

Weight (KG):

-

4000

-

Capacity:

-

all size customize

-

Model:

-

BCO

-

Brand:

-

Yutsai

-

Certification:

-

ISO9001:2008

-

Weight:

-

500kg

-

Feature:

-

OEM

Quick Details

-

Type:

-

Drying Oven

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yutsai

-

Voltage:

-

220v/380v, 220v/380v

-

Power:

-

3kw

-

Dimension(L*W*H):

-

can choose

-

Weight (KG):

-

4000

-

Capacity:

-

all size customize

-

Model:

-

BCO

-

Brand:

-

Yutsai

-

Certification:

-

ISO9001:2008

-

Weight:

-

500kg

-

Feature:

-

OEM

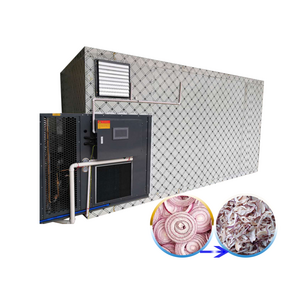

Hot air circulation drying equipment

Structure of industrial ovens

Industrial oven inside and outside the two-tier structure, the housing of sheet steel angle between the inner and outer double shell filled with fibrous material. Fibrous material industrial oven used mostly aluminum, it can play the role of insulation, forming a reliable insulation. Industrial oven is equipped with hot air circulation system and temperature measurement and control system.

Principle of industrial ovens

Industrial ovens at work, the operator to obtain industrial oven interior temperature value through the instrument and temperature sensor, operated by the control system. Industrial oven hot air circulation heating method, compared with conventional cooling heating, has a better gas flow, can speed up industrial oven drying speed of the material.

Hot air circulation system consists of industrial oven air motors, wind turbines and electric composed, motor driven blower wheel sends cold wind, cold air through an electric heating device to carry heat through the duct into the industrial oven oven studio.

Industrial hot air circulating oven system helps improve the uniformity of air temperature in the process of industrial ovens switch box door transportation of materials, the temperature value will be affected are changed, the uniformity of the hot air circulation system is conducive to the rapid recovery in the largest degree temperature operating conditions.

|

Feature: |

|

|

1. |

The machine with automatic cooling return system to facilitate the collection of product. |

|

2. |

The heating section is divided into three independent control, cooperate with the SCR action. |

|

3. |

Teating system: each section of the upper and lower heating body can be adjusted, equal temperature. |

|

4. |

Temperature range: normal temperature+10℃-30℃(MAX). |

|

5 . |

Insulation structure: high temperature rock cotton, thermal insulation 100mmAir heat insulation. |

|

6. |

Transmission system: the use of Japanese Panasonics transmission components, with the use of glass fiber mesh. |

|

Note: import and export section and heating length, width, etc. can be designed and manufactured according to customers requirements.

|

|

We also supply automation machine:

Service we can supply:

We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

After-sales service support

After we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the product you purchased properly to your hands.

Technological support

Yutsai has been largely adopting new technologies, new techniques and high-tech equipments. And Yutsai also has strict and effective quality control system.

Package and shipping & work shop: