- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2100x1000x1650mm

-

Year:

-

2020

-

Power (kW):

-

3

-

Weight (KG):

-

1080

-

Mode Number:

-

GB4235 Horizontal Band Saw Machine

-

Type:

-

Band Saw Machines

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

Horizontal

-

Application:

-

Metal Cutting For Automatic Machine

-

Precision:

-

High Precision

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

weiren, weiren

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

2100x1000x1650mm

-

Year:

-

2020

-

Power (kW):

-

3

-

Weight (KG):

-

1080

-

Mode Number:

-

GB4235 Horizontal Band Saw Machine

-

Type:

-

Band Saw Machines

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

Horizontal

-

Application:

-

Metal Cutting For Automatic Machine

-

Precision:

-

High Precision

Product Parameter of GB4235

|

Model |

GB4 2 35 |

|

|

Max. Cutting Diameter |

Round: 350 |

mm |

|

Square: 3 50 * 4 50 |

mm |

|

|

Blade Speed |

27.45.69 |

m/min |

|

Blade Size |

1.1*34* 4115 |

mm |

|

Main Motor |

3 |

kw |

|

Hydraulic motor |

0.37 |

kw |

|

Cooling motor |

0.09 |

kw |

|

Machine Size(L*W*H) |

2100x1000x1650 |

mm |

|

Machine weight |

1.08 |

ton |

|

Vice clamping |

Hydraulic |

|

|

Blade tension form |

Manual |

|

|

Feeding cut adjust way |

Hydraulic |

|

|

Feeding way |

Manual |

|

|

Chip conveyor way |

Manual |

|

|

Cooling way |

Water cooling |

|

|

Voltage |

380V 50HZ 3Phase |

|

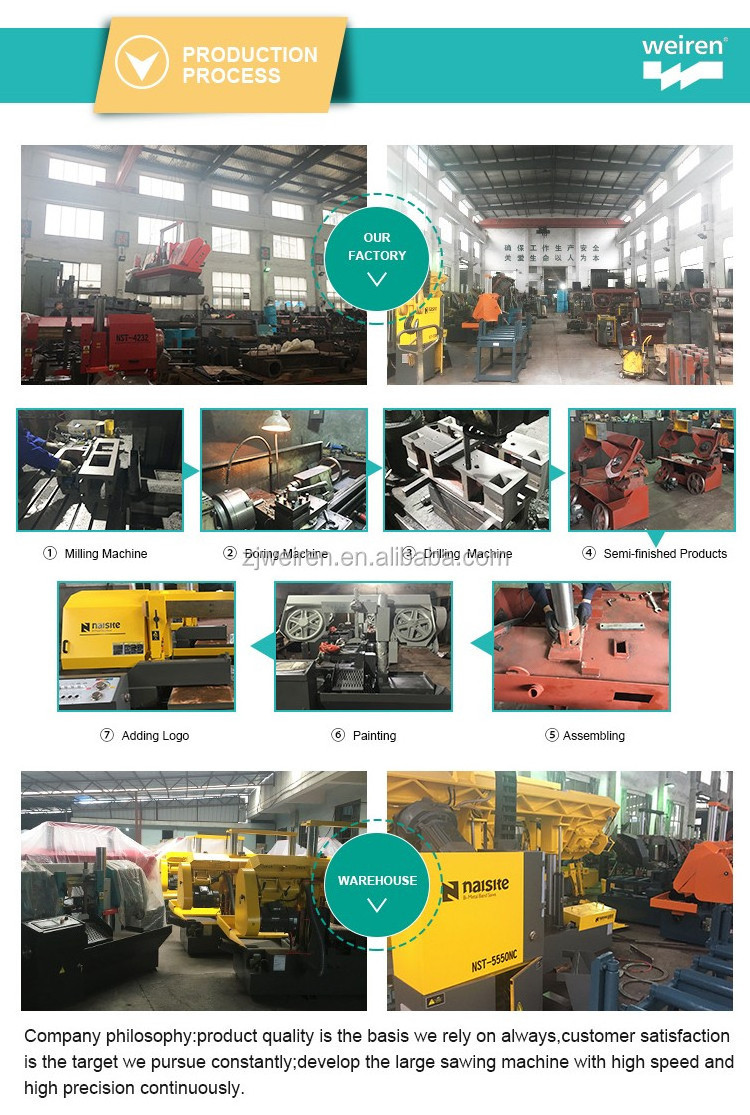

Main character:

Single pillar horizontal belt saw machine is our company's own design and manufacture of metal belt saw machine, home and abroad product essence. The structure is scientific and reasonable, the appearance is generous, the cutting efficiency is high, and the service life of the saw

blade

is long. It is an ideal discharge equipment for large and medium materials.

Main features:

1. Adopt a manual hydraulic clamp structure, the workpiece enters the sawing position from behind the sawing machine, and uses the clamp to fix the workpiece and perform sawing.

2. Design its own unique sawing belt guide clamping device to improve the working conditions, prolong the service life, and reduce noise to reduce environmental pollution.

3

. Single column double cylinder structure, plus one auxiliary column greatly lengthens the service life of the machine tool and

prolong the

service life of the saw blade.

4. Centralized button switch control panel

5

. Cutting speed hydraulic control, stepless speed adjustment.

6

. Saw wire speed adopts triangular belt three-level speed adjustment.

7

. Saw-cutting is stable and has high accuracy.

8

. Hydraulic clamping is adopted for easy operation.

The company adopts high quality materials, precision machine tools, and processes according to the process specifications.

1. Transmission Parts

The worm

-

wheel is made of tin bronze materials and is processed on a precision

gear-

hob using a precision worm

-

hob. After

quenching

, the worm is

processing

in a precision worm grinder

,then the worm-wheel

high surface finish and high precision. The box body adopts HT250 cast iron, which guarantees the processing accuracy with the special boring mode, and the worm wheel has a long service life.

2. Column

Hard Chrome surface grinding is very wear-resistant, its guide sleeve is made of self-wear wear resistant materials, no crawling phenomenon will occur during the work, the two of the small gap, good rigidity, good vertical sawing section.

3. Hydraulic components

The inner wall of the cylinder and the piston are both hard Chrome Plated and sealed with the world famous brand. Therefore, there is no crawling leakage and high durability.

4. Electrical section

The wiring is neat, the structure is reasonable, the heat dissipation is strong. The main electrical component adopts the Zhengtai product.

Details display

Details display