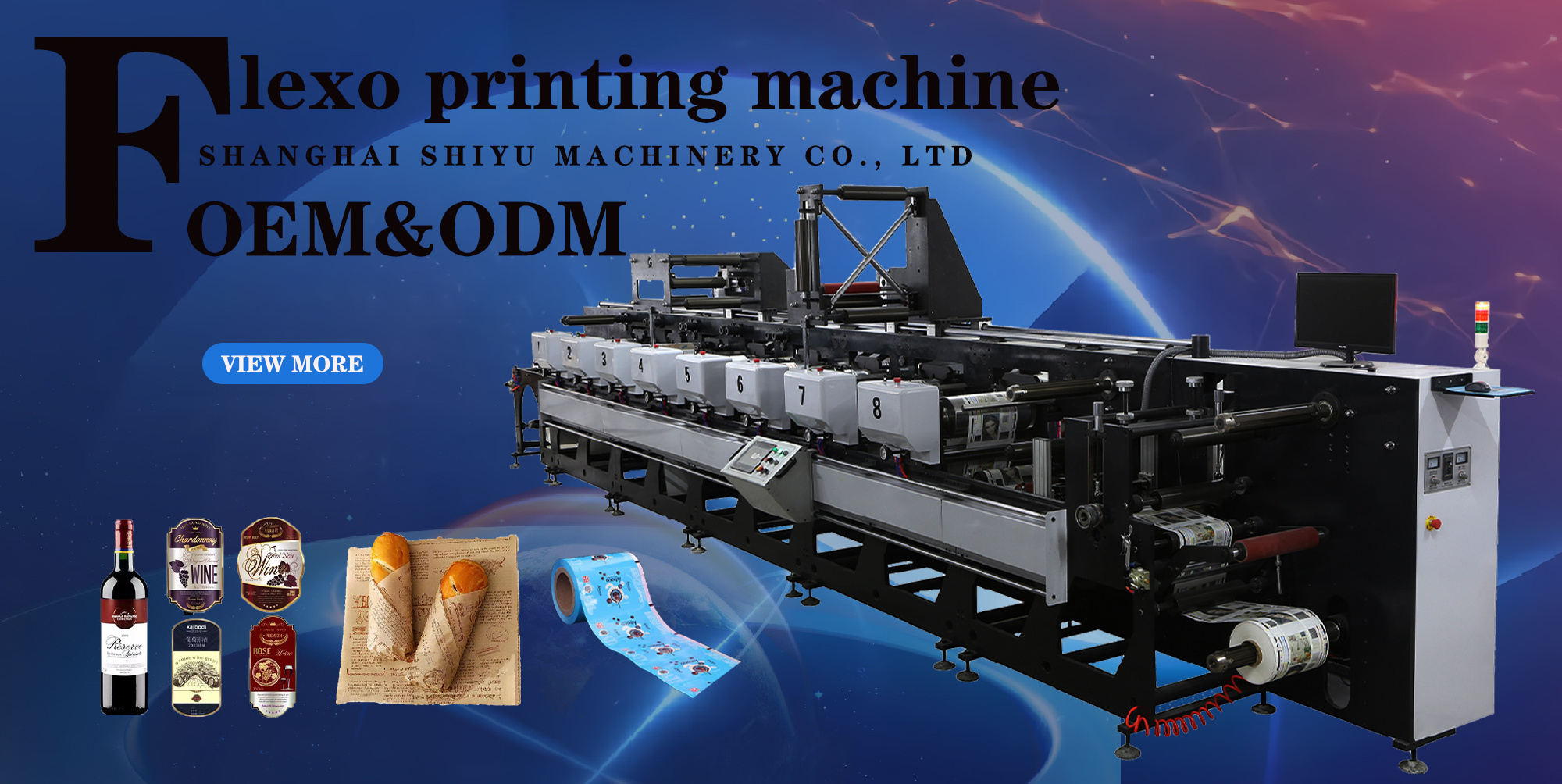

- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

6200mm*1850mm*1850mm

-

Weight:

-

6000 KG

-

Rewinding diameter:

-

600mm

-

Unwinding Diamete:

-

600mm

-

Printing Width:

-

320mm

-

Web width:

-

320mm

-

Options:

-

Laminationi

-

Printing Page:

-

Single Faced

-

Anilox Roller:

-

Ceramic Anilox Roller

-

Dryer:

-

UV& IR

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SY

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

6200mm*1850mm*1850mm

-

Weight:

-

6000 KG

-

Rewinding diameter:

-

600mm

-

Unwinding Diamete:

-

600mm

-

Printing Width:

-

320mm

-

Web width:

-

320mm

-

Options:

-

Laminationi

-

Printing Page:

-

Single Faced

-

Anilox Roller:

-

Ceramic Anilox Roller

-

Dryer:

-

UV& IR

Features:

1, Adopts the anilox roller to spread ink.

2, Unwinding and rewinding are controlled by magnetic power brake, clutch, (or by automatic tension controller of Mitsubishi).

3, Each printing unit adopts 360 degree for color registration.

4. Each printing unit has one IR drier.

5. The rubber roller can break away automatically while stopping and running at a low speed in order to avoid ink dried.

6. The main motor is equipped with import stepless regulation of frequency conversion.

7. Unwinding, web guiding, corona treatment, printing, IR drying and rewinding can be finished in one process.

8, An ideal machine to print many kinds of paper rolls before cup making steps.

1, Adopts the anilox roller to spread ink.

2, Unwinding and rewinding are controlled by magnetic power brake, clutch, (or by automatic tension controller of Mitsubishi).

3, Each printing unit adopts 360 degree for color registration.

4. Each printing unit has one IR drier.

5. The rubber roller can break away automatically while stopping and running at a low speed in order to avoid ink dried.

6. The main motor is equipped with import stepless regulation of frequency conversion.

7. Unwinding, web guiding, corona treatment, printing, IR drying and rewinding can be finished in one process.

8, An ideal machine to print many kinds of paper rolls before cup making steps.

|

model

|

SY-320

|

|

Printing speed

|

50m/min

|

|

Printing color

|

6colors

|

|

Web width

|

320mm

|

|

Printing width

|

310mm

|

|

Unwinding diameter

|

600mm

|

|

Rewinding diameter

|

600mm

|

|

Printing length

|

175-355mm

|

|

Precision of registration

|

±0.10mm

|

|

Dimensions

|

6200mm*1850mm*1850mm

|

|

Machine weight

|

6000kg

|

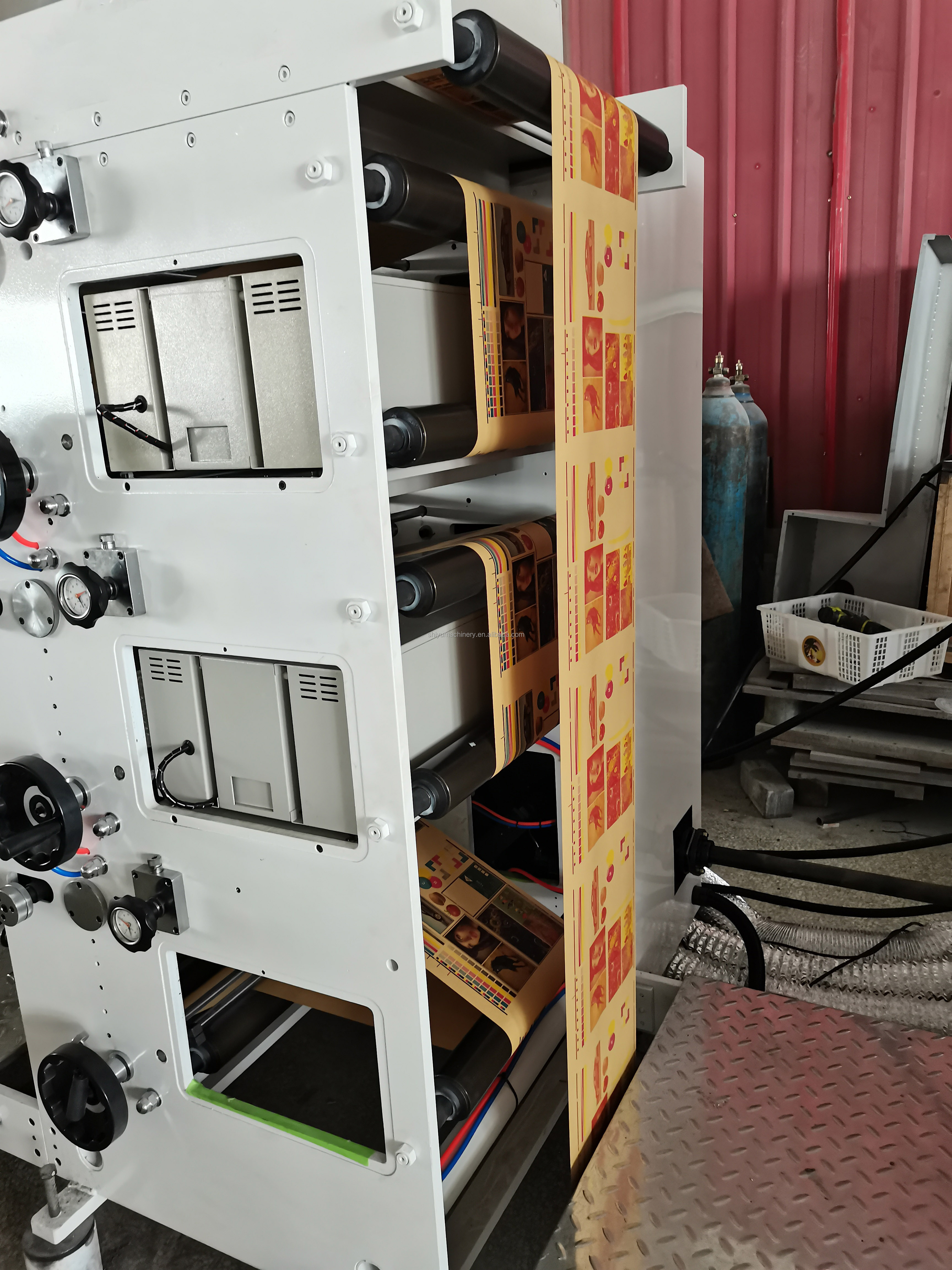

Details Images

control panel

1).Power Supply, Stop Button, Start Button and Emergency Stop. 2).Temperature Controller for each Heating Oven. 3).Anilox RollerRotation Button for each Printing Station. Length Counter and Speed Controller

4)bottom roller tension control

hydraulic lifting system for unwinding and rewinding

Standard Cantilever unwinding station,maximum unwind diameter: 600mm . 76mm (3″) air shaft roller. Electromagnetic power brake. Auto tension control–No roll-followers or external sensors to be adjusted or maintained. Support a stable unwinding tension.

Printing Unit

Printing station comes with ink rubber roller, ceramic anilox cylinder, printing plate cylinder, scrapper blade and ink

container.helical gear .

container.helical gear .

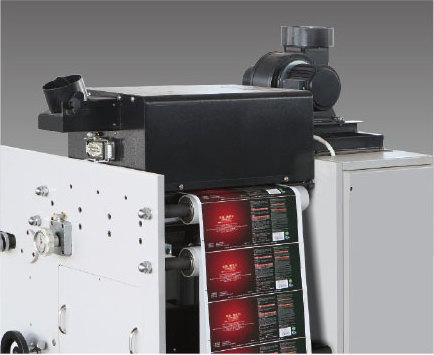

UV dryer system

1).Each Printing Unit comes with 1 Unit Infrared Heating Drying Oven. 2).Infrared Heating Drying Oven is placed on material andafter each printing station.

Web Guide System

Detection mode: Edge checking

Control paper move straightly.

Control paper move straightly.

Winding unit

Max unwind material diameter: 600

With Magnetic brake

Die Cutting Unit

Rotary die cutting. Magnetic cylinder need to be customized according to your label size Flexible dies can be customized according to your demand

Automatic constant tension control

tension is control pulling material tight or loose.machine come with two Set Auto Constant Tension Controller For Unwind and Rewinding.

Printed samples

Hot Searches