- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DINGLI

-

Voltage:

-

220V-10KV

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

300

-

Weight (KG):

-

73000 KG

-

Product Name:

-

Wood Pellet Production Line

-

Material:

-

Steel

-

Color:

-

Blue or Customized

-

Capacity(t/h):

-

4.5-5.0

-

Early moisture(%):

-

35-50%

-

Final moisture(%):

-

12-25%(adjustable)

-

Type:

-

Biomass Pellet Mill

-

Process:

-

Crushing, drying and dewatering, removal ash, molding

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Online support

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

4500 - 5000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DINGLI

-

Voltage:

-

220V-10KV

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

300

-

Weight (KG):

-

73000 KG

-

Product Name:

-

Wood Pellet Production Line

-

Material:

-

Steel

-

Color:

-

Blue or Customized

-

Capacity(t/h):

-

4.5-5.0

-

Early moisture(%):

-

35-50%

-

Final moisture(%):

-

12-25%(adjustable)

-

Type:

-

Biomass Pellet Mill

-

Process:

-

Crushing, drying and dewatering, removal ash, molding

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Online support

Biomass energy is second only to coal, oil and natural gas one of the world's total energy consumption 4th.According to experts predict that biomass energy is likely to become an important part of the future sustainable energy system, at the middle of this century, using new technology to produce all kinds of biomass alternative fuels will account for more than 40% of total global fuel consumption.

Because the biomass as fuels has no contamination, and other significant characteristics of renewable, thus it increasingly brought to the attention of the countries.

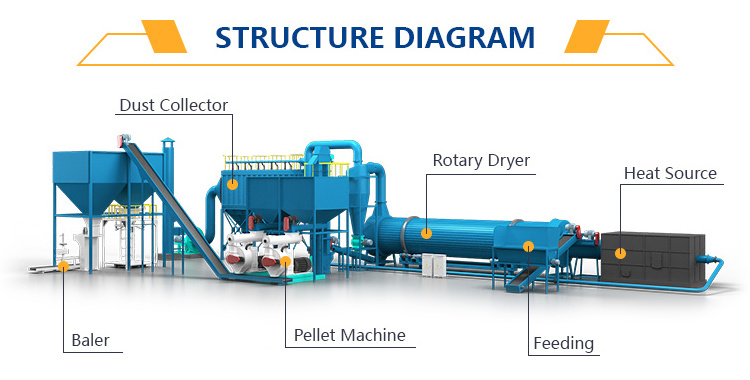

Complete Biomss Pellet Production Line consists of heater, feeding machine, rotary drum, discharging machine, induced draft fan, unloading feeder, cyclone, odor removal equipment and power distribution cabinet.

Biomass Pellet Production Line is is used for various of material, such as wood powder, straw, wood chips, sawdust, corn straw, wheat straw, rice straw, cotton straw, peanut shell, branch, saw powder, bagasse, sunflower seed shell, bamboo shavings, wood shavings, barley straw, oat straw, rye, straw, sorghum straw, corn stalks, stem drying potato vines, beans, peanut vine,etc.

Main Features

1.Patent technology (patent no. : ZL200920089749.2), single equipment the kinds are variety, application to a variety of materials, modular structures, optimize configurations, ensure production lines broad applicability.

2.According to customer's requirements to realize intelligent control, a key "fool" type operation.

3.More than 300 users in the world, our factory has the rich practical experience.

4.The cover area reduce 50% than the traditional drying granulating production line , civil investment reduce about 50%.

5.waste gas discharge temperature is lower than 50 ℃, low energy consumption.

6.Particle shaping fuel rate of 98%, bulk density and high density.

7.Special design ash control technology, ash content lower than 1%.

8.Modular dust collecting and purifying heat recycling configuration, safe and protect environmental.

9.This type mixing drum dryer is supporting many new type energy-saving hot air stove,energy consumption drop about 30%,power consumption reduce 20%,lower operation costs.

10.Internet sharing system, it can ensure that the personalized production lines , accessories and unit efficient distributions in place.

2.According to customer's requirements to realize intelligent control, a key "fool" type operation.

3.More than 300 users in the world, our factory has the rich practical experience.

4.The cover area reduce 50% than the traditional drying granulating production line , civil investment reduce about 50%.

5.waste gas discharge temperature is lower than 50 ℃, low energy consumption.

6.Particle shaping fuel rate of 98%, bulk density and high density.

7.Special design ash control technology, ash content lower than 1%.

8.Modular dust collecting and purifying heat recycling configuration, safe and protect environmental.

9.This type mixing drum dryer is supporting many new type energy-saving hot air stove,energy consumption drop about 30%,power consumption reduce 20%,lower operation costs.

10.Internet sharing system, it can ensure that the personalized production lines , accessories and unit efficient distributions in place.

|

Model

|

DLKL1000

|

DLKL1500

|

DLKL2000

|

DLKL3000

|

DLKL5000

|

|||||

|

Capacity(t/h)

|

0.8-1.0

|

1.2-1.5

|

1.5-2.0

|

2.5-3.0

|

4.5-5.0

|

|||||

|

Motor Power(KW)

|

135

|

175

|

210

|

255

|

300

|

|||||

|

Weight(T)

|

45

|

47

|

55

|

68

|

73

|

|||||

|

Plant Area(m)

|

10m*24m

|

10m*24m

|

10m*24m

|

12m*26m

|

12m*26m

|

|||||

|

Note: the marked price is only part of the stand-alone machine price, the complete production line machine price can be got by leaving a message or consult us online, the engineer will give you a quotation after accounting.

|

|

|

|

|

|

|||||

Hot Searches