- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0~80KW

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3500 KG

-

Marketing Type:

-

Hot Product

-

Product Name:

-

fementer / fermentation tank / fermenting vessel

-

Application:

-

Brewing Beer

-

Function:

-

Liquild Fermentation

-

Keywords:

-

Fermentation Tank Beer

-

Material:

-

SUS304/SUS316/red Copper

-

Capacity:

-

100L-20000L

-

Usage:

-

Brewery Pub Hotel

-

Cooling way:

-

Dimple Jacket Plate

-

Control system:

-

PLC

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Shandong

-

Brand Name:

-

TIANTAI

-

Voltage:

-

3phase/380(customizable)

-

Power:

-

0~80KW

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3500 KG

-

Marketing Type:

-

Hot Product

-

Product Name:

-

fementer / fermentation tank / fermenting vessel

-

Application:

-

Brewing Beer

-

Function:

-

Liquild Fermentation

-

Keywords:

-

Fermentation Tank Beer

-

Material:

-

SUS304/SUS316/red Copper

-

Capacity:

-

100L-20000L

-

Usage:

-

Brewery Pub Hotel

-

Cooling way:

-

Dimple Jacket Plate

-

Control system:

-

PLC

-

Certification:

-

ISO

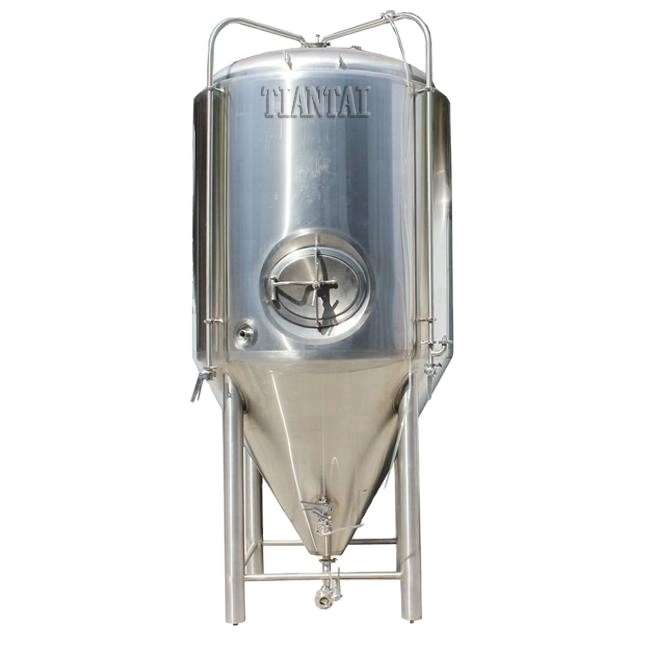

3500L Conical Beer Fermentation Tank

Our Fermentation Tank/Unitank is made of high-quality stainless steel material of international standard. Polyurethane foam is used for high voltage insulation. The shell can be polished, matte, carbon steel, sprayed and other forms according to customer requirements.

| Volume | ID/OD | Material |

| 50L | 400mm/500mm | 304/316L/Copper |

| 100L | 500mm/600mm | 304/316L/Copper |

| 200L | 650mm/810mm | 304/316L/Copper |

| 500L | 800mm/960mm | 304/316L/Copper |

| 800L | 900mm/1060mm | 304/316L/Copper |

| 1000L | 1050mm/1210mm | 304/316L/Copper |

| 1200L | 1200mm/1360mm | 304/316L/Copper |

| 1500L | 1400mm/1560mm | 304/316L/Copper |

| 3000L | 1600mm/1760mm | 304/316L/Copper |

| 5000L | 1600mm/1760mm | 304/316L/Copper |

Note: The size of the tank can be customized according to the brewing process or site. The above parameters are for reference only. Plesse refer to the actual design plan.

Description

Using international beer standard fermentation production technology, real-time detection of online data, remote monitoring technology can be realized, and the mirror polishing inside the tank can reach the polishing quality standard of 0.2~0.4μm, which fully meets the automatic cleaning of the programmable controller Automatic control requirements for disinfection systems.

The cooling jacket of the fermentation tank also conforms to the technical standards of various countries in the world. It provides a variety of jacket heat exchange methods, such as Maitreya plate, arch channel, tile channel and so on. Meet the technical requirements of heat exchange for different cooling media and pressures.

Standard Configuration

| Function | Wort Fermentation or maturation |

| Interior Shell | SUS304 full welded; TH=3mm |

| Exterior Shell | SUS304 full welded; TH=2mm |

| Welding | 100% TIG welding with pure argon gas shield |

| Insulation | Polyurethane; TH=80mm |

| Glycol Jacket | Dimpled plate on cone and side |

| Leakage Test | By water and pressured gas |

| Clean | CIP arm with 360° coverage CIP spraying ball |

Features

1.Made by 304/316L SS, TIG automatically welded

2.Design comply with requirements of GB/PED/ASME

3.Polished to 0.4 microns,360 degree cleaning without deadcorner

4.55-90 degrees cone design, suitable for yeast discharge

5.Rotary beer racking arm with horizontal design for less lose

6.Cooling jacket on side wall and cone,auto temp control

7.Pressure adjustable for pressured and non-pressured fermentation

8.Allow dry hopping for IPA and other beer

Details Show

Fully committed to research, development and experience accumulation on brewing craftdiversification, design customi-zation, operation automation, management process, we introduced a series of advanced production processing and test-ing equipment which greatly improved the stability and controllability of fabrication quality, and lays a good foundation forproduct customization and production standardization.

More Brewing Equipment

Our product variety,complete in specifications.At the same time,wo have a deep foundation of cooperation with many of domestic and foreign companies and research institutions. We are specialized in professional design,manufacture,installation and commissioning of various beer equipments and supporting facilities.Which includes saccharification equipment,fermentation equipment,yeast spresd cultivation equipment,refrigeration equipment for small and medium-sized brewery,hotel,bar and etc.

Customized Service

We adopt strictly the production process of German beer equipment. Our designed and manufactured products meet both domestic and foreign customers’ demands. Our equipment with its fine workmanship, excellent performance, and convenient operation will be your best choice for brewing beer. In both the appearance and the quality, our products are comparable to the top level of similar products domestically or internationally. Furthermore, we offer to cater to the need of customers. Our engineers are happy to design and manufacture various beer equipments according to customers’ demand.

ABOUT US

TIANTAl Beer EquipmentCo. Ltd,a well-recognized manufacturer in beerbeverage equipment industry,turnkey solutions.provider in beer beverage projects, is ounded in 2012 and based in Jinan, China. Tiantai mainly pro-vides a full set of equipment and services involved in beer production for various medium and large craft beer breweries, medi-um-sized industrial breweries and research institute. Tiantai also supplies winery equipment, distillery equipment and biologi-cal fermentation equipment.

TIANTAl has established multiple overseas service centers around the world, provided high-qualityproducts and fast services to more than 1,800 users globally, covering 94 countries and regionsaround the world, and has won the trust and praise of users globally.

LEAVE US A MESSAGE BELOW NOW↓↓↓↓↓