- Product Details

- {{item.text}}

Quick Details

-

Surface Finish:

-

TSHS

-

Application:

-

Decoration

-

Hardness:

-

<=26

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DY

-

Model Number:

-

DY-HANDRAIL SPHERE

-

Certification:

-

ISO

-

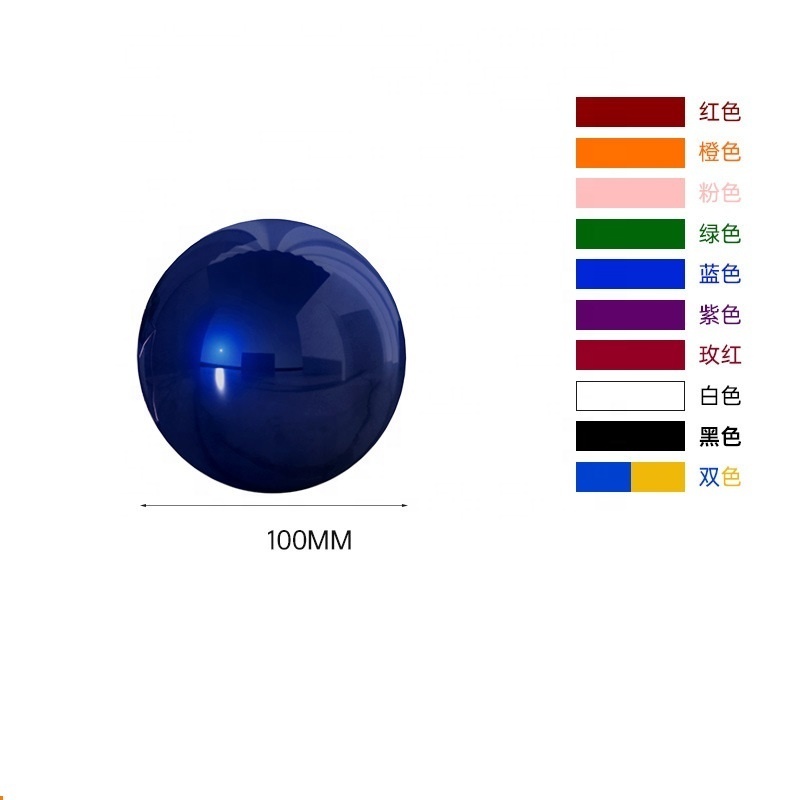

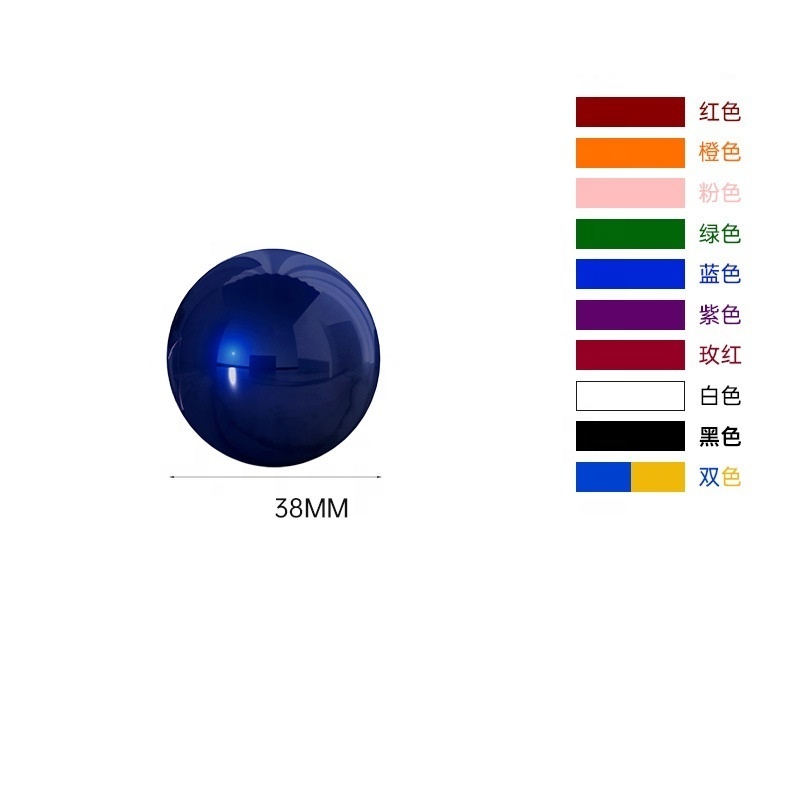

Color:

-

Optional

-

Magnetisim:

-

None

-

Applied technique:

-

Welding, molding and polishing

Quick Details

-

Grade:

-

300 Series

-

Tolerance:

-

±3%

-

Steel Grade:

-

316L, 304

-

Surface Finish:

-

TSHS

-

Application:

-

Decoration

-

Hardness:

-

<=26

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DY

-

Model Number:

-

DY-HANDRAIL SPHERE

-

Certification:

-

ISO

-

Color:

-

Optional

-

Magnetisim:

-

None

-

Applied technique:

-

Welding, molding and polishing

Q:What are your finish options?

A:Yes, we offer a wide range of options to meet different requirements from our clients regarding size/diameter, thickness, color and material and so on. Options include: stainless 304 and 316 or 201, powder coat, paint, galvanized plate, or natural rust finish. Our powder coated finish has an undercoated zinc plate for outdoor use, which also eliminates the need for maintenance and rusting.

Q:What is your lead time?

A:Our general lead time is 10-15 days but may extend during peak periods.

Q: Is there any maintenance required?

A:304 steel is enduring indoors and should be kept from water. 316 is the best steel on the market with overwhelming capability against water-erosion. Long term exposure to the elements and environment will cause changes and a continuation of the rusting process. If this is not desired, we recommend a small degree of maintenance.

Technique Applied

Two discs were cut on a circle shear. Then they were taken to a spinning lathe where the disks were shaped against a hemispherical steel mold.

Obviously some of the design constraints and parameters were set by the parts I was re-using from the drill press. This did introduce some less than optimal limitations -- such as the use of 19mm bearings, meaning that the mains-shaft of the lathe was also limited to 19mm in diameter. If this turns out to be too weak I'll just go buy some bigger bearings and make a new shaft.

Other than the legacy components, there was the issue of exactly what I had sitting in my metal rack and scrap bin -- which wasn't much.

Apart from the main-shaft, just about everything on this lathe was made from 25mm square or 25x50mm CRS 1020 steel bar stock.

There are no castings -- it's just cut to size and bolted together.

The main spindle and the backplate were turned from 304 steel which is much nicer to work with than plain old 1020. The chips from 304 are small and blunt and -- unlike the razor sharp shards that come off 304 when it's milled or turned. If you're planning to turn anything out of steel, do yourself a favor and get some free-machining stock such as 201 or 304.

DETAILS:

|

P hysical capability of stainless steel balls |

||||

|

CAPABILTY MODEL |

201 |

302 |

304 |

316 |

|

Tensile strength |

100,000 - 180,000 psi |

100,000-180,000 psi |

100,000 - 180,000 psi |

90,000 psi |

|

Yield strength |

50,000 - 150,000 psi |

50,000-150,000 psi |

50,000 - 150,000 psi |

45,000 psi |

|

Tensibility |

55-60% |

55-60% |

55 - 60% |

35% |

|

Modulus of Elasticity |

29,000,000 psi |

29,000,000 psi |

29,000,000 psi |

28,000,000 psi |

|

Density |

280lbs/cubic inch |

286lbs/cubic inch |

286 lbs/cubic inch |

290lbs/cubic inch |

| AISI Number | C % | Si % | Mn % | Cr % | Ni % | Mo % | P % | S % | Character |

| AISI 302 | 0.15 Max | 1.00 Max | 2.00 Max | 17.0~ 19.0 | 8.0~ 10.5 | 0.045 Max | 0.03 Max | Slightly magnetic Austinitic | |

| AISI 304 | 0.07 Max | 1.00 Max | 2.00 Max | 17.0~ 19.0 | 8.50~ 10.5 | 0.045 Max | 0.03 Max | Slightly magnetic Austinitic | |

| AISI 316 | 0.07 Max | 1.00 Max | 2.00 Max | 16.5~ 18.5 | 10.5~ 13.5 | 2000~ 2.50 | 0.045 Max | 0.03 Max | Non magnetic Austinitic Excellent corrosion resistance |

| AISI 420J | 0.17~ 0.25 | 1.00 Max | 1.00 Max | 12.0~ 14.0 | 0.045 Max | 0.03 Max | magnetic Hardenable HRC 48 Min fair corrosion resistance | ||

| AISI 430 | 0.08 max | 1.00 Max | 1.00 Max | 15.5~ 17.5 | 0.045 Max | 0.03 Max | fair- good corrosion resistance | ||

| AISI 440C | 0.95~ 1.20 | 1.00 Max | 1.00 Max | 16.0~ 18.0 | 0.40~ 0.80 | 0.04 Max | 0.02 Max | fair corrosion resistance Hardenable HRC 58 Min |

Corrugated carton, opp bag and foam

Production Procedures