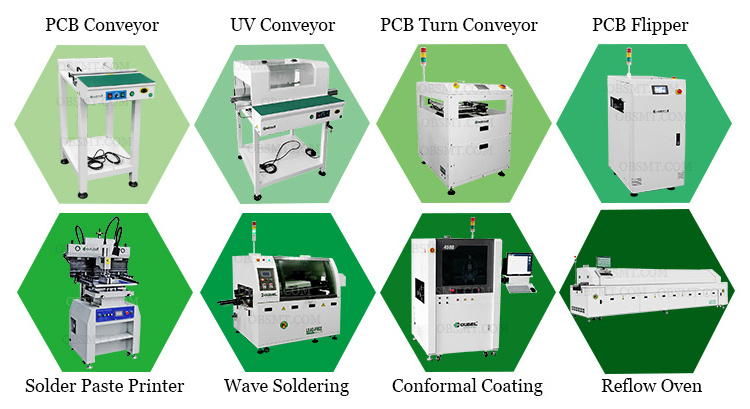

Oubel is highly regarded for its world-class quality products, produced with the flexibility and nimbleness demanded by its customers all over the world.

Under your witness, we will continue to work hard, strive for innovative research and development of more advanced equipment.