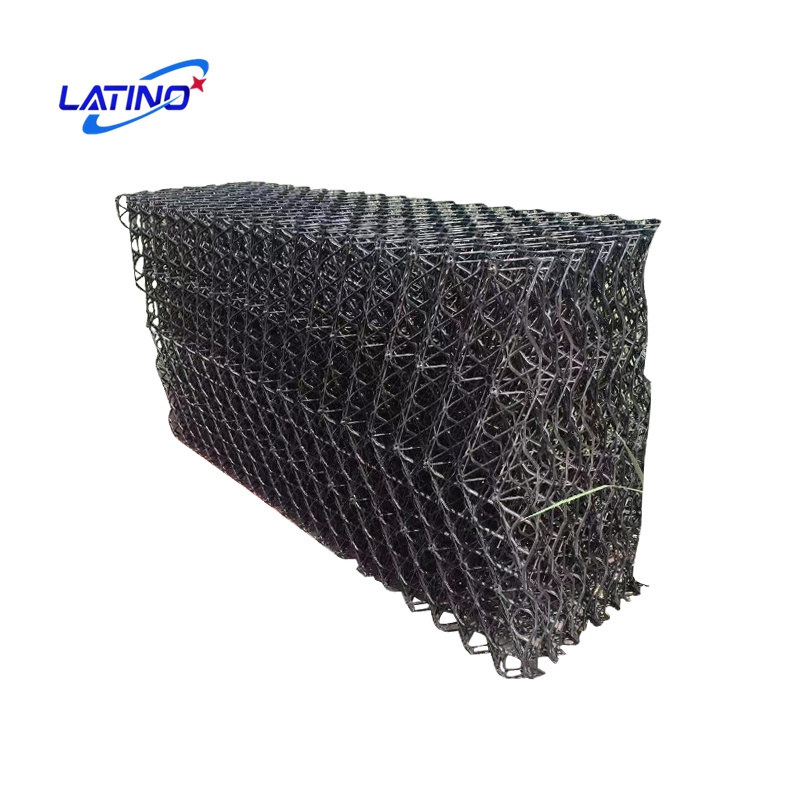

High stability

Environmentally friendly

Economical installation

Long service life

Impact resistant