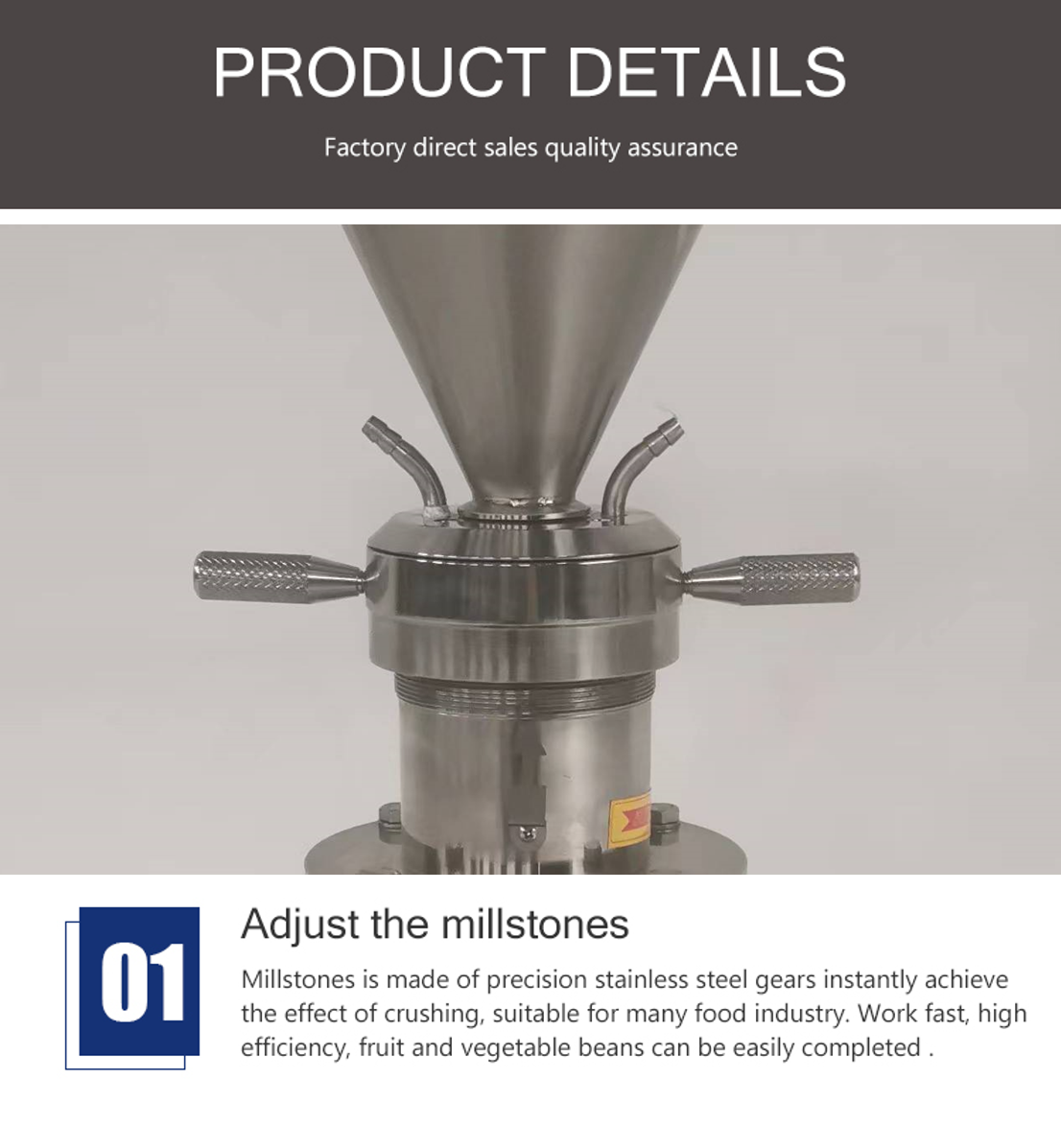

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1500W

-

Dimension(L*W*H):

-

400X500X700

-

Weight:

-

50 KG

-

Output product name:

-

Colloid mill

-

Type:

-

Nuts Processing Equipment

-

Application:

-

Food Industry

-

Emulsified size:

-

2-40um

-

Product name:

-

Seed Beans Roasting Machine

-

Speed:

-

2800r/min

-

Heating:

-

Electricity Steam Gas Heating

-

Material:

-

Stainless Steel 304/316L

Quick Details

-

Brand Name:

-

FUNLE

-

Place of Origin:

-

ZHEJIANG

-

Voltage:

-

220-450V

-

Power:

-

1500W

-

Dimension(L*W*H):

-

400X500X700

-

Weight:

-

50 KG

-

Output product name:

-

Colloid mill

-

Type:

-

Nuts Processing Equipment

-

Application:

-

Food Industry

-

Emulsified size:

-

2-40um

-

Product name:

-

Seed Beans Roasting Machine

-

Speed:

-

2800r/min

-

Heating:

-

Electricity Steam Gas Heating

-

Material:

-

Stainless Steel 304/316L

Product Description

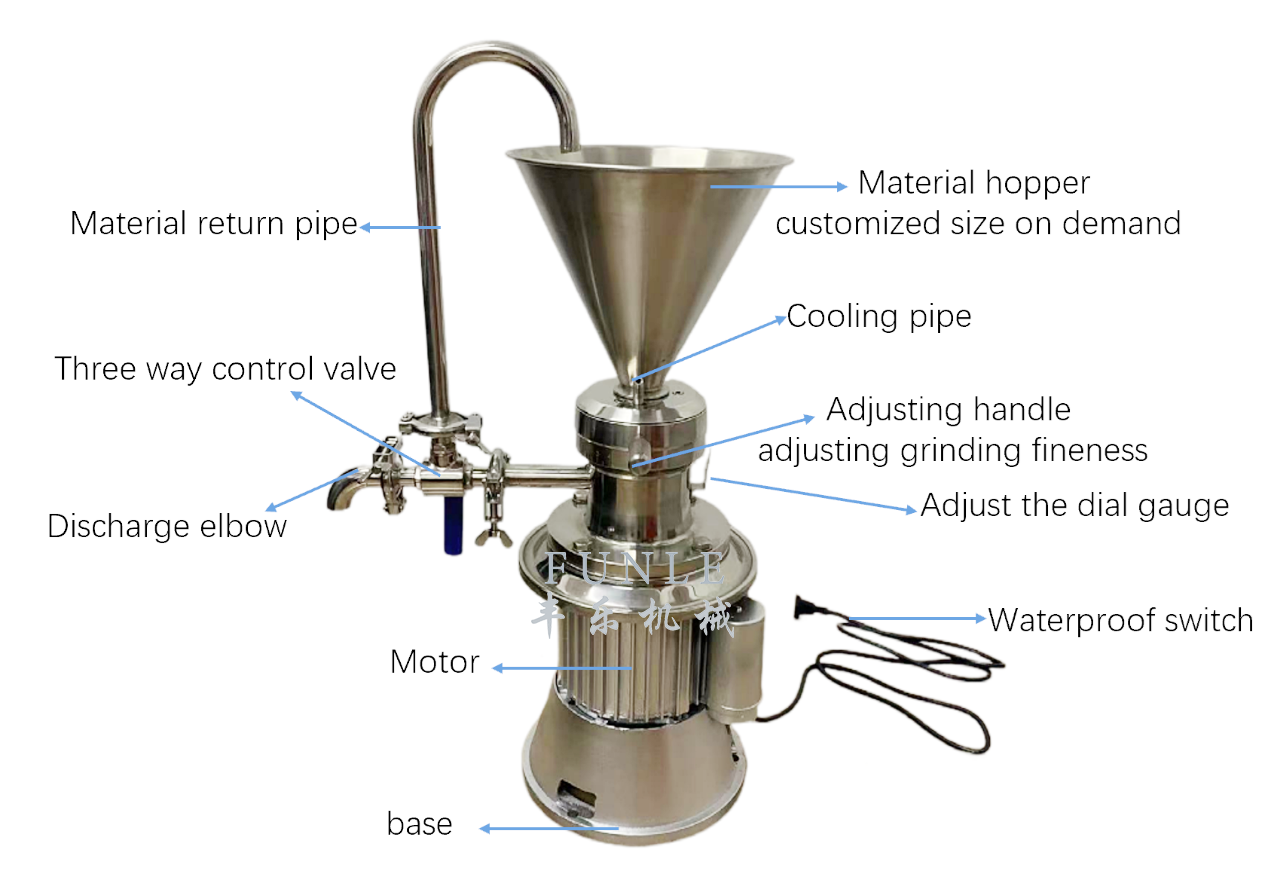

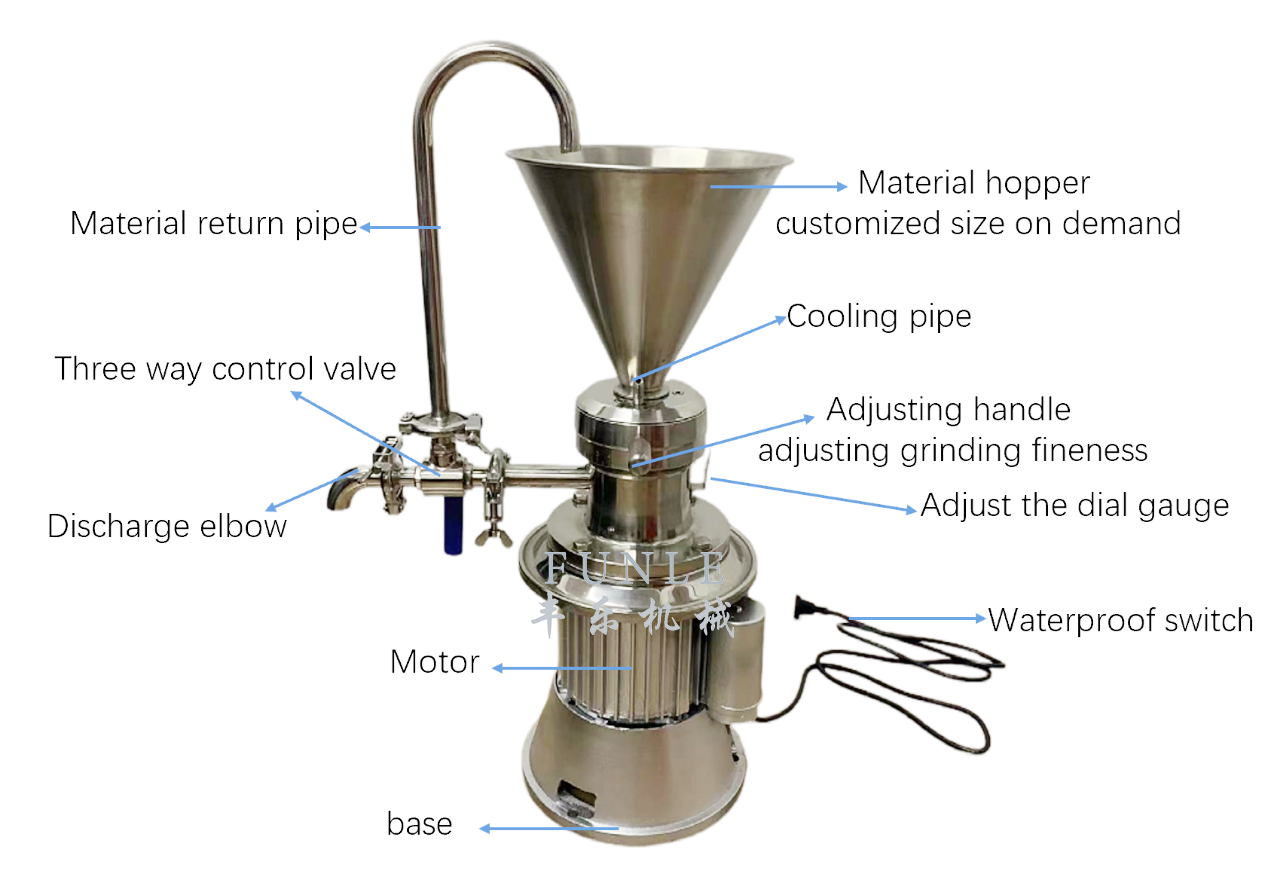

Product name: High productivity peanut butter making colloid mill sesame paste machine

Product Principle

Wet ultrafine particle crushing

Homogenizing, emulsifying, mixing, crushing

Can replace the stone, sand mill, ball mill

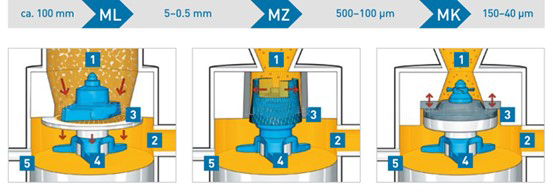

Working Principle

Colloid mill is shearing, grinding as well as high-speed stirring applied force, grinding is finished depending on the relative movement of tooth-form slope, one of them rotates at high speed, while the other stays still to make materials that passing between tooth-form slopes receive great shear force and friction, and to grind, emulsify, smash, homogenize and mix them under

complex forces such as high-frequency shake, high-speed, vortex and others at the same time, so as to achieve the effect of fine and super micro.

Main technical parameter

|

Model

|

Fineness(μm)

|

Output (T/H)

|

Mill diameter (MM)

|

Speed (RPM)

|

Power (KW)

|

|

JML-50

|

2-40

|

0.01-0.1

|

50

|

2980

|

1.1(220/380V)

|

|

JMF-50

|

|

|

|

|

1.5(220/380V)

|

|

JML-65

|

|

0.02-0.5

|

65

|

|

1.5(220/380V)

|

|

JMF-65

|

|

|

|

|

2.2(220/380V)

|

|

JML-80

|

|

0.5-1

|

80

|

|

3

|

|

JMF-80

|

|

|

|

|

4

|

|

JML-100

|

|

0.5-2

|

100

|

|

5.5

|

|

JMF-100

|

|

|

|

|

7.5

|

|

JML-120

|

|

1-3

|

120

|

|

7.5

|

|

JMF-120

|

|

|

|

|

7.5

|

|

JML-140

|

|

1-4

|

140

|

|

7.5

|

|

JMF-140

|

|

|

|

|

11

|

|

JMF-180

|

|

2-8

|

180

|

|

15/18.5

|

|

JMF-200

|

|

2-10

|

200

|

|

22

|

|

JMF-220

|

|

3-15

|

220

|

|

30

|

|

JMF-260

|

|

5-18

|

260

|

|

45

|

Note:

(L) stands for vertical type,(F) represents split type.The output of the colloid mill will vary based on the properties of the material, the concentration of the material, and the fineness of the grinding.In the table The maximum yield is calculated using water as the medium.

Application

Mainly used in Food industry,Chemistry in dustry,Daily Chemical Industry,Medical industry, Construction industry,Paper making industry,Pesticide industry,ects.

APPLICABLE INDUSTRY

1. About Delivery term

Q: What's the delivery term for doing business with you?

A: EXW/FOB/CIF/DDU… it depends on preference of clients.

2. About Lead time

Q: What's the leading time after placing order?

A: After getting your confirmation, mixing tank about 25 days, pump 15 days, colloid mill 10 days. However, it depends on

production schedule is in slack or peak season, and the complication of machines.

3. About Payment time

Q: What's the payment term?

A: T/T 40% as down payment, 60% balance payment before delivery.

4. About Quality

Q: How do you control your quality?

A: All machines before delivery will be tested and send video for customer, if no problem then arrange balance payment.

Meanwhile,CE is available for customers' needs.

5. About Packing

Q: How do you pack the machines?

A: Standard export wooden case, to avoid damage during delivery.

6. About Customized

Q: Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings.

Q: What's the delivery term for doing business with you?

A: EXW/FOB/CIF/DDU… it depends on preference of clients.

2. About Lead time

Q: What's the leading time after placing order?

A: After getting your confirmation, mixing tank about 25 days, pump 15 days, colloid mill 10 days. However, it depends on

production schedule is in slack or peak season, and the complication of machines.

3. About Payment time

Q: What's the payment term?

A: T/T 40% as down payment, 60% balance payment before delivery.

4. About Quality

Q: How do you control your quality?

A: All machines before delivery will be tested and send video for customer, if no problem then arrange balance payment.

Meanwhile,CE is available for customers' needs.

5. About Packing

Q: How do you pack the machines?

A: Standard export wooden case, to avoid damage during delivery.

6. About Customized

Q: Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings.

Hot Searches