- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YunTian

-

Dimension(L*W*H):

-

65*10*25m DQL2500/3000.40

-

Weight (KG):

-

7560 kg

-

Item:

-

Stacker reclaimer

-

Classified by different funcations:

-

Stacker,wheel bucket reclaimer,wheel bucket stacker&reclaimer

-

Application:

-

Widely used to stack and reclaim bulk cargoes, coal, ore in port.

-

Rated loading capacity:

-

Wheel bucket type

-

Transmission:

-

Mechanical

-

Control method:

-

Variable frequency

-

Wheel bucket type:

-

No lattice

-

Support form:

-

Cart / Trolley

-

Type & Density:

-

Coal 0.85~1

-

Product name:

-

Widely Used Coal Stacker Reclaimer Price for Sale

Quick Details

-

Warranty:

-

1 Year

-

Marketing Type:

-

Hot Product 2021

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YunTian

-

Dimension(L*W*H):

-

65*10*25m DQL2500/3000.40

-

Weight (KG):

-

7560 kg

-

Item:

-

Stacker reclaimer

-

Classified by different funcations:

-

Stacker,wheel bucket reclaimer,wheel bucket stacker&reclaimer

-

Application:

-

Widely used to stack and reclaim bulk cargoes, coal, ore in port.

-

Rated loading capacity:

-

Wheel bucket type

-

Transmission:

-

Mechanical

-

Control method:

-

Variable frequency

-

Wheel bucket type:

-

No lattice

-

Support form:

-

Cart / Trolley

-

Type & Density:

-

Coal 0.85~1

-

Product name:

-

Widely Used Coal Stacker Reclaimer Price for Sale

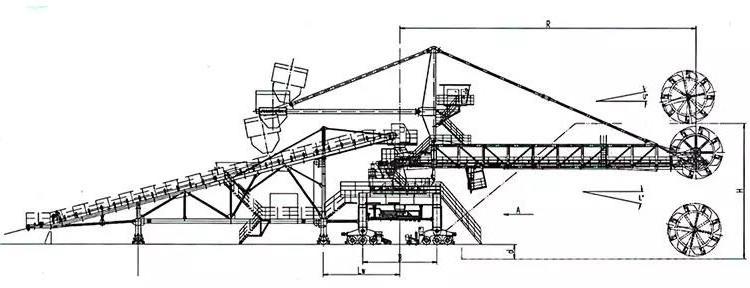

Coal bucket wheel stacker reclaimer for sale

Introduction of stacker reclaimer:

Stacker and reclaimer is widely applied to stack and reclaim bulk cargoes(coal,oretc).Stacker and reclaimer is mainly composed of steel structure,jib belt conveyor,feeder tripper,luffing mechanism,slew mechanism,travel mechanism,spray system,wheel bucket device,electricalsystem,necessary safety related components and accessory devices.Stacker and reclaimer jib could slew,luffing,prolong or shorten itself.And end turning bucket is material grab device.

Stacker reclaimer generally includes the following units:

1.Steel structure

2.Jib belt conveyor

3.Feeder tripper

4.Luffing mechanism

5.Slew mechanism

6.Travel mechanism

7.Spray system

8.Wheel bucket device

9.Electrical system

10.Other accessory safety related components and accessory devices.

Please click here for details communication

Use of stacker reclaimer:

Widely used in power plant, ports, steel, chemical plants, cement and other basic industry raw material field, apply and bar or circular storage yard, which can realize the coal, iron ore, such as lime disperses the shape of raw materials, taking the continuous operation.

Referenced standards:

1.GB/T14695-93 jib-form wheel bucket stacker and reclaimer type parmeters.

2.JB/T7326-94 wheel bucket stacker and reclaimer safety regulation.

3.JB/T7328-94 wheel bucket stacker and reclaimer receipt &inspection specification.

4.GB3811-2008 crane design criterion.

5.GB6067-85 lifting equipments safety regulation.

Technical data of stacker reclaimer:

| Type |

DQL450/ 600.25 |

DQL1000/ 1250.30 |

DQL1800/ 2000.35 |

||

| Capacity |

Rated capacity |

Stacker | 600t/h | 1250t/h | 2000t/h |

|

Reclaimer |

450t/h | 1000t/h | 1800t/h | ||

| Capacity | Height |

Above rail |

10m | 11m | 12m |

|

Below rail |

2m | 2m | 2m | ||

| Material |

Type&density |

Coal 0.85~1t/m 3 |

Coal 0.85~1t/m 3 |

Coal 0.85~1t/m 3 |

|

| Granularity | 0~300mm | 0~300mm | 0~300mm | ||

| Reclaimer |

Wheel bucket type |

No lattice | No lattice | No lattice | |

|

Wheel bucket dia |

4.21m | 6m | 7m | ||

|

Rotating speed |

6~10r/min | 7.817r/min | 7.5r/min | ||

|

Bucket no.&capacity |

7×0.22m 3 | 8×0.5m 3 | 8×1m 3 | ||

| Transmission | Mechanical | Mechanical | Mechanical | ||

| Transfer tape |

Feedstock& discharging |

Width | 1200mm | 1400mm | 1600mm |

| Speed | 2.5m/s | 3.45m/s | 3.45m/s | ||

|

Slewing mechanism |

Slewing dia | 25m | 30m | 35m | |

| Slewing angle | ±110° | ±110° | ±110° | ||

| Slewing speed |

0.046~0.154 |

0.06~0.16 |

0.1~0.2 |

||

| Control mechod |

Variable frequency |

Variable frequency |

Variable frequency |

||

| Support form |

Cross roller bearing |

Cross roller bearing |

Tapered roller |

||

|

Traveling mechanism |

Track guage | 5m | 6m | 7m | |

| Base | 6m | 7m | 7m | ||

| Speed | Slow | 7m/min | 7m/min | 7m/min | |

| Fast | 30m/min | 30m/min | 30m/min | ||

|

Max.wheel pressure |

200KN | 200KN | ≤250KN | ||

|

Recommed track |

P43/P50 | P43/P50 |

QU80/ QU100 |

||

|

Luffing mechanism |

Luffing Angle |

Face upward |

13° | 13° | 13° |

| bow | 8° | 8° | 8° | ||

|

Luffing speed |

3~6 m/min |

4.3~6 m/min |

4~5.5 m/min |

||

|

Installed capacity |

180 | 280 | 360 | ||

| Size | Length | 52.6m | 51.19m | 61.4m | |

| Width | 7m | 8.58m | 9m | ||

| Height | 17m | 21m | 23.5m | ||

Advantages of stacker reclaimer:

1. Advanced design methods:such as computer aided design, three-dimensional design and optimization design of steel structure.

2. Advanced technology:combined with material piling and taking machine design and manufacture of the summary of experience and constantly improve.

3. Advanced production equipment and technology : such as steel pretreatment line can guarantee the quality of the products and corrosion resistant ability, the use of large milling and boring machine to improve the machining quality of large parts.Big knot file within the overall play, drive part of the plant commissioning, rotating part adopts mould preparation.

4. Use new materials, such as wear-resistant materials, composite materials.

5. Outside fittings adopt domestic first-class products and advanced foreign products.

6. The soft start and frequency conversion control, reduce the impact damage to the equipment.

7. Equipment set up various protection measures.

8. Advanced testing means and strict quality management system.

Click Here to Fill Out Your Inquiry in The Text Box to Get The Latest Quotation.

YunTian Group products meet the factory, workshop, port, mining, waste disposal, goods scattered, petrochemical, aerospace, military and other industries of universal bridge crane, overhead crane, eot crane, door crane, universal gantry crane, rubber tyre and rail mounted container gantry crane four link type portal crane, quayside container crane, crane, crane hook, mining grab crane, gantry crane, ship loader, grab bucket ship unloader, stacker reclaimer, dredger, mobile platforms and other types of hydraulic crane technical requirements.