- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2390x1560x3610mm

-

Weight (T):

-

5

-

CNC or Not:

-

CNC

-

Certification:

-

ISO 9001

-

Frame:

-

high Rigid stainless steel

-

Control System:

-

PLC

-

clutch:

-

dry clutch

-

Color:

-

customized

-

Punching material:

-

Metal

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KINGLAN or Customer Logo

-

Voltage:

-

380/440

-

Dimension(L*W*H):

-

2390x1560x3610mm

-

Weight (T):

-

5

-

CNC or Not:

-

CNC

-

Certification:

-

ISO 9001

-

Frame:

-

high Rigid stainless steel

-

Control System:

-

PLC

-

clutch:

-

dry clutch

-

Color:

-

customized

-

Punching material:

-

Metal

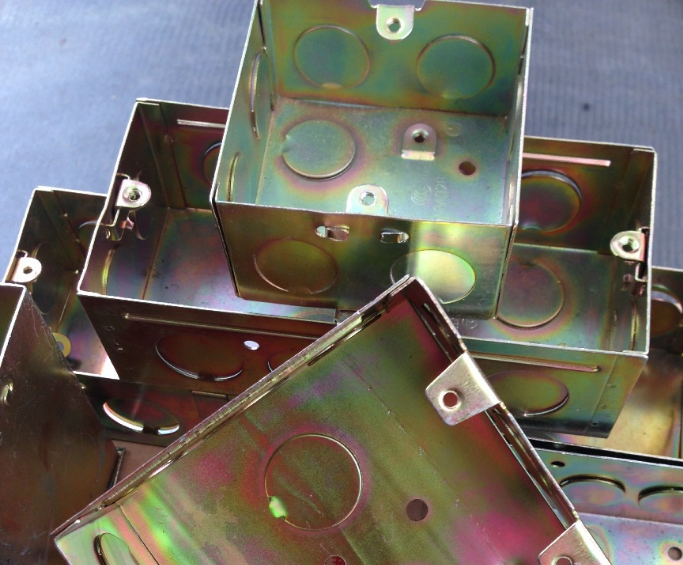

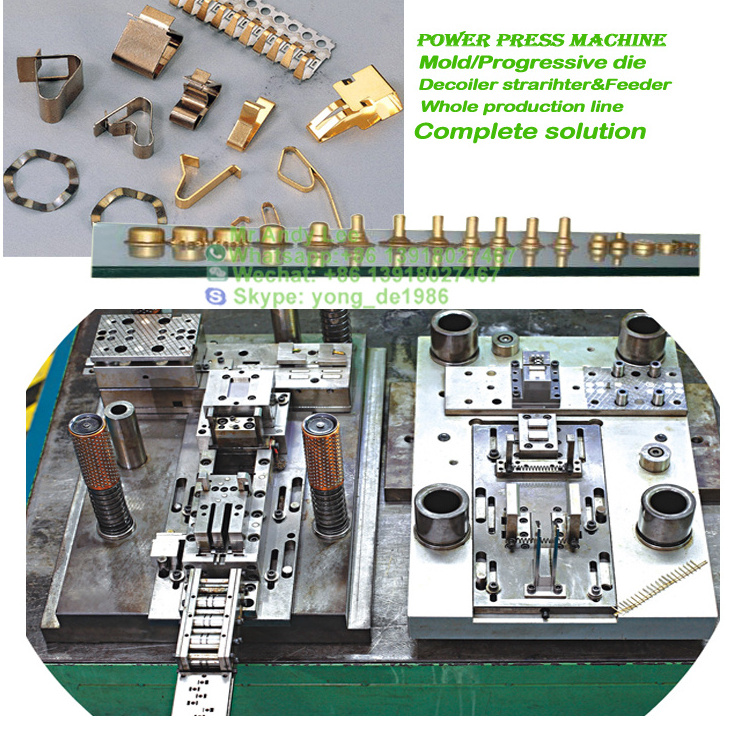

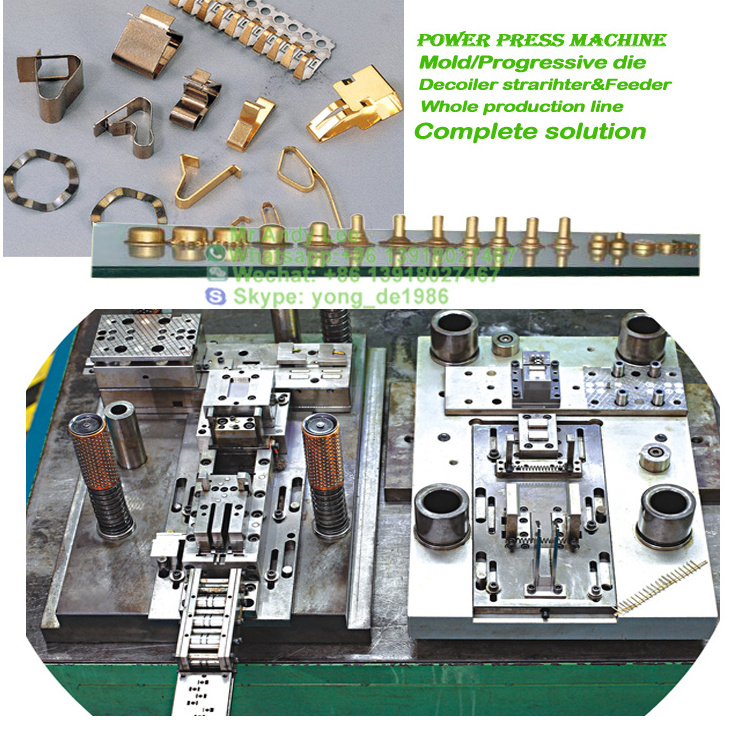

We could provide the whole line solution including power press, feeder and decoiler, mold, manipulator, Transfer system, robot, etc.

In all our years of manufacturing quality power presses and other power press products, we have made it our goal to put the customer first. We believe in offering the right solution to meet your needs, whether it is having the right parts to fix your existing machines, the presses you need at an affordable price, or the ongoing support to keep your machines in top condition.

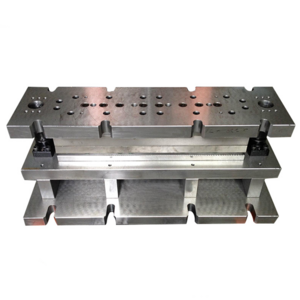

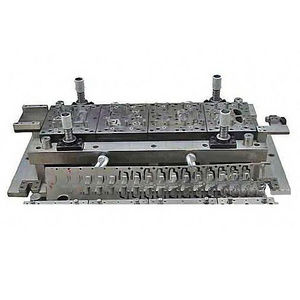

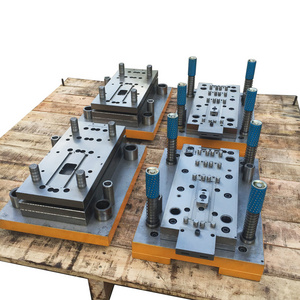

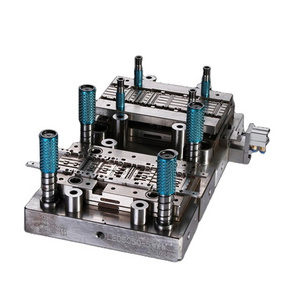

Progressive die design & Manufacturing

| ALP Feature |

|

1.One-Piece Steel welded body, tempering treatment, accuracy and stability;

|

| Model | ALP-25 | ALP-35 | ALP-45 | ALP-60 | ALP-80 | |||||||

| Type | V | H | V | H | V | H | V | H | V | H | ||

| Capacity | Ton | 25 | 35 | 45 | 60 | 80 | ||||||

| Pated Tonnage Point | mm | 3.2 | 1.6 | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | 4 | 2 | |

| Speed Changing | s.p.m | 60-140 | 130-200 | 40-120 | 110-180 | 40-100 | 100-150 | 30-90 | 80-120 | 35-80 | 80-120 | |

| Stable Speed | s.p.m | 110 | 85 | 75 | 65 | 65 | ||||||

| Stroke | mm | 60 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | 150 | 70 | |

| Die Height | mm | 200 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | 340 | 380 | |

| Slide Adjustment | mm | 50 | 55 | 60 | 75 | 80 | ||||||

| Slide Area | mm | 300*220*50 | 360*250*50 | 400*300*60 | 500*360*70 | 560*420*70 | ||||||

| Bolster Area | mm | 680*300*70 | 800*400*70 | 850*440*80 | 900*500*80 | 1000*550*90 | ||||||

| Shank Hole- | mm | 38 | 38 | 38 | 50 | 50 | ||||||

| Main Motor | kw.p | 2.2*4 | 2.2*4 | 37.*4 | 5.5*4 | 5.5*4 | ||||||

| Slide Adjust Device | HP | Electric Driving | ||||||||||

| Air Pressure | kg/cm2 | 6 | 6 | 6 | 6 | 6 | ||||||

| Presses Precision | CNS(JIS)1Class | CNS(JIS)1Class | CNS(JIS)1Class | CNS(JIS)1Class | CNS(JIS)1Class | |||||||

| Presses Dimension | mm | 1280*850*2200 | 1380*900*2400 | 1600*950*2500 | 1600*1000*2800 | 1800*1180*2800 | ||||||

| Presses Weight | ton | 2.1 | 3 | 3.8 | 5.6 | 6.5 | ||||||

| Die Cushion Capacity | ton | - | 2.3 | 2.5 | 3.6 | 3.6 | ||||||

| Stroke | mm | - | 50 | 50 | 70 | 70 | ||||||

| Die Cushion Effective Area | mm2 | - | 300*230 | 300*230 | 350*300 | 450*310 | ||||||

| Model | ALP-80 | ALP-110 | ALP-160 | ALP-200 | ALP-260 | |||||||

| Type | V | H | V | H | V | H | V | H | V | H | ||

| Capacity | Ton | 80 | 110 | 160 | 200 | 260 | ||||||

| Pated Tonnage Point | mm | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | |

| Speed Changing | s.p.m | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | |

| Stable Speed | s.p.m | 65 | 50 | 35 | 35 | 30 | ||||||

| Stroke | mm | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | |

| Die Height | mm | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | |

| Slide Adjustment | mm | 80 | 80 | 100 | 110 | 120 | ||||||

| Slide Area | mm | 560*420*70 | 650*470*80 | 700*550*90 | 850*630*90 | 950*700*100 | ||||||

| Bolster Area | mm | 1000*550*90 | 1150*600*110 | 1250*800*140 | 1400*820*160 | 1500*840*180 | ||||||

| Shank Hole | mm | 50 | 50 | 65 | 65 | 65 | ||||||

| Main Motor | kw.p | 5.5*4 | 7.5*4 | 11*4 | 15*4 | 18.5*4 | ||||||

| Slide Adjust Device | HP | Electric Driving | ||||||||||

| Air Pressure | kg/cm2 | 6 | 6 | 6 | 6 | 6 | ||||||

| Presses Precision | CNS(JIS)1Class | CNS(JIS)1Class | CNS(JIS)1Class | CNS(JIS)1Class | CNS(JIS)1Class | |||||||

| Presses Dimension | mm | 1800*1180*2800 | 1900*1300*3200 | 2300*1400*3800 | 2615*1690*4075 | 2780*1850*4470 | ||||||

| Presses Weight | ton | 6.5 | 9.6 | 16 | 23 | 32 | ||||||

| Die Cushion Capacity | ton | 3.6 | 6.3 | 10 | 14 | 14 | ||||||

| Stroke | mm | 70 | 80 | 80 | 100 | 100 | ||||||

| Die Cushion Effective Area | mm2 | 450*310 | 500*350 | 650*420 | 710*480 | 810*480 | ||||||

| STANDARD ACCESSORIES"•" | OPTIONAL ACCESSORIES"°" |

| • Hydraulic Overload Protector | ° Electrical Automatic Lubrication System |

| • Manual Drive Lubrication System | ° Pneumatic Die Cusion Device |

| • Inverter | ° Preset Counter |

| • Electrical Slide Adjust Device | ° Preset Counter |

| • Electrical Die Height Indicator | ° Foot Switch |

| • Balance Device |

° Quick Die Change Device

(Die lifter, Clamp And Die Arm shift mode) |

| • Rotary Cam Switch | ° Slide Knock-Out Device |

| • Crank Angle Indicator | ° Misfeed Detect Consent |

| • Electric Stroke Counter | ° Power Supply |

| • Air Source Receptacle | ° Anti Vibration Press Mount |

| • Against Over-Run Safety Device | ° Photo-Electronic Safety Device |

| • Maintenance Tool Box | ° Feeder |

| • Operation Manual | ° Uncoiler |

| ° Leveler | |

| ° Mechanism Hand | |

| ° Die Room Light |