- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.25-0.7 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Toppo Machinery

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

About 6.8*1.6*1.25m (L*W*H)

-

Weight:

-

3250 kg

-

Marketing Type:

-

Easy to operate

-

Feature:

-

high production speed

-

Control System:

-

fully automatic

-

Operation Language:

-

Chinese/English/Spanish

-

Suitable Material:

-

Q235 or similar

-

Raw Material:

-

PPGI/Galvanized Sheet

-

Delivery Time:

-

35 working days after deposit

-

Color of Machine:

-

blue, gray, or your required color

-

After Warranty Service:

-

Video technical support

Quick Details

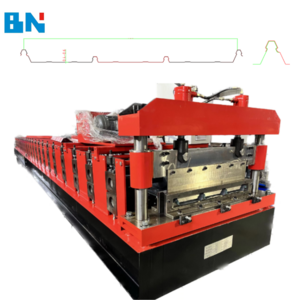

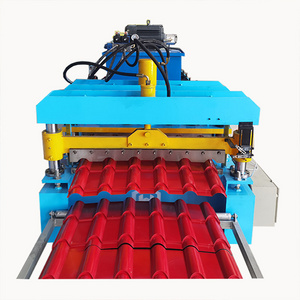

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

0-25 m/min

-

Rolling thinckness:

-

0.25-0.7 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Toppo Machinery

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

About 6.8*1.6*1.25m (L*W*H)

-

Weight:

-

3250 kg

-

Marketing Type:

-

Easy to operate

-

Feature:

-

high production speed

-

Control System:

-

fully automatic

-

Operation Language:

-

Chinese/English/Spanish

-

Suitable Material:

-

Q235 or similar

-

Raw Material:

-

PPGI/Galvanized Sheet

-

Delivery Time:

-

35 working days after deposit

-

Color of Machine:

-

blue, gray, or your required color

-

After Warranty Service:

-

Video technical support

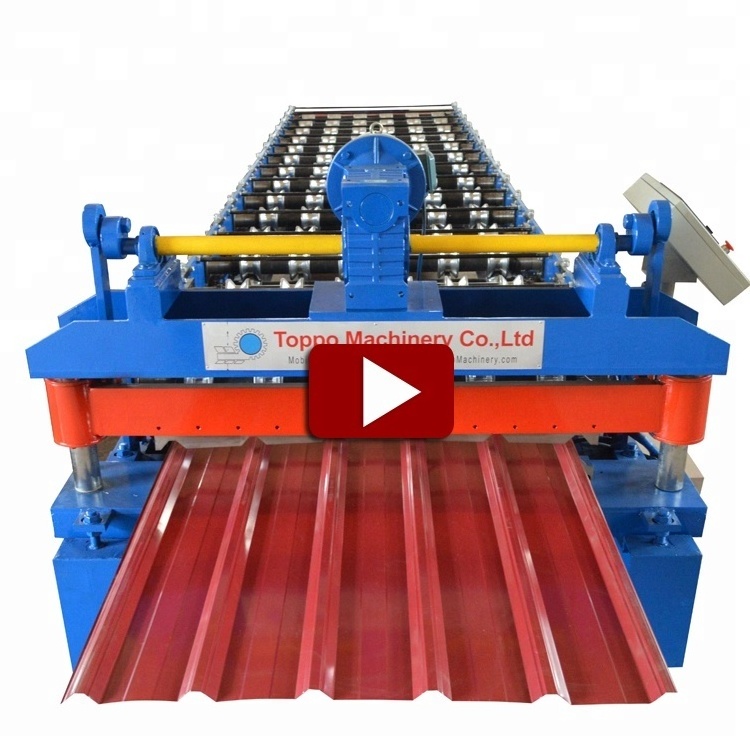

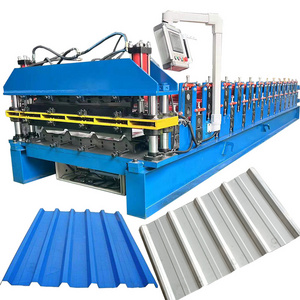

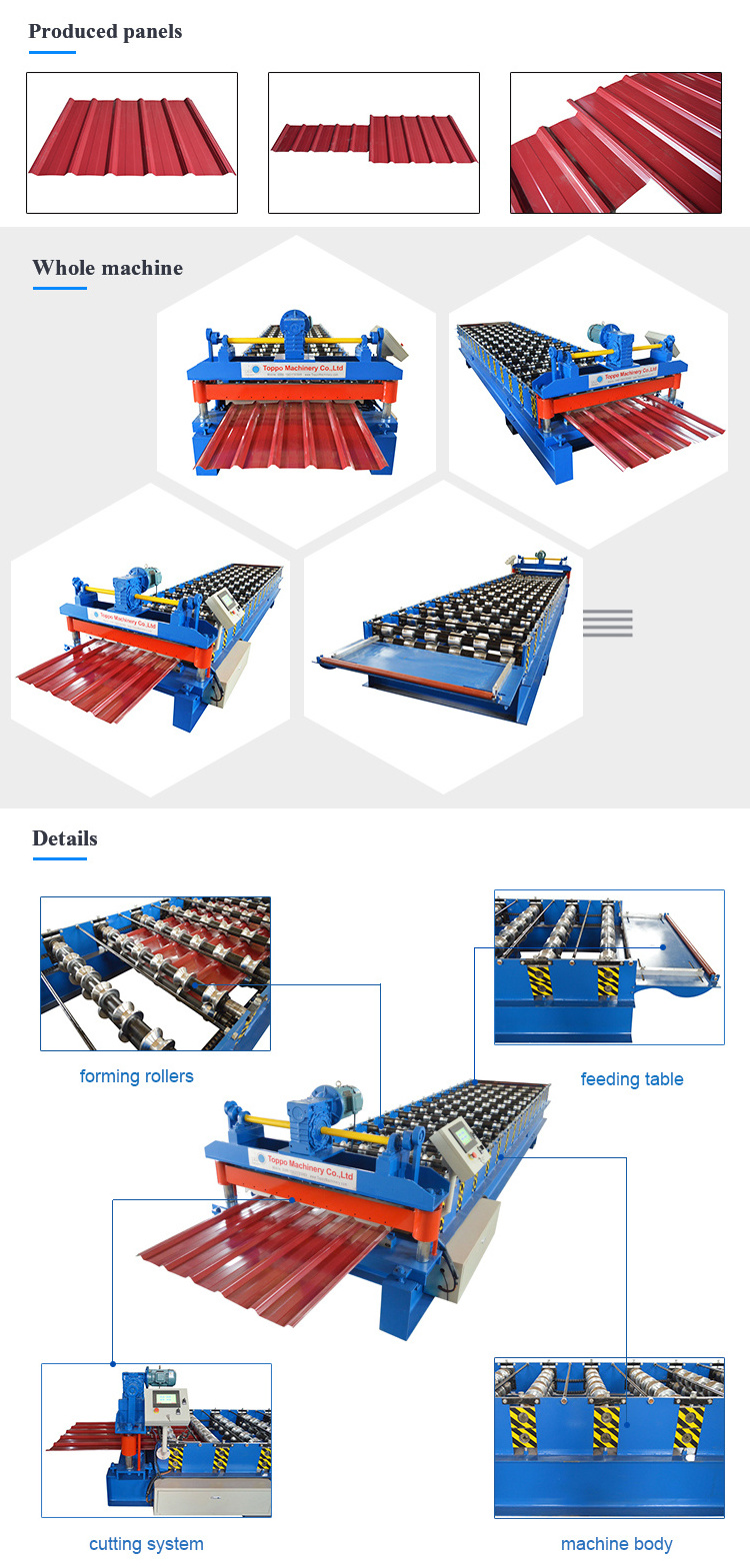

High Quality Zinc Roofing Color Steel IBR Sheet Roll Forming Machine

we can produce most of the products according to your requirements, not just the

size of the products on this page.

After-sales service, guaranteed, trustworthy

You can send an inquiry to know more product information.

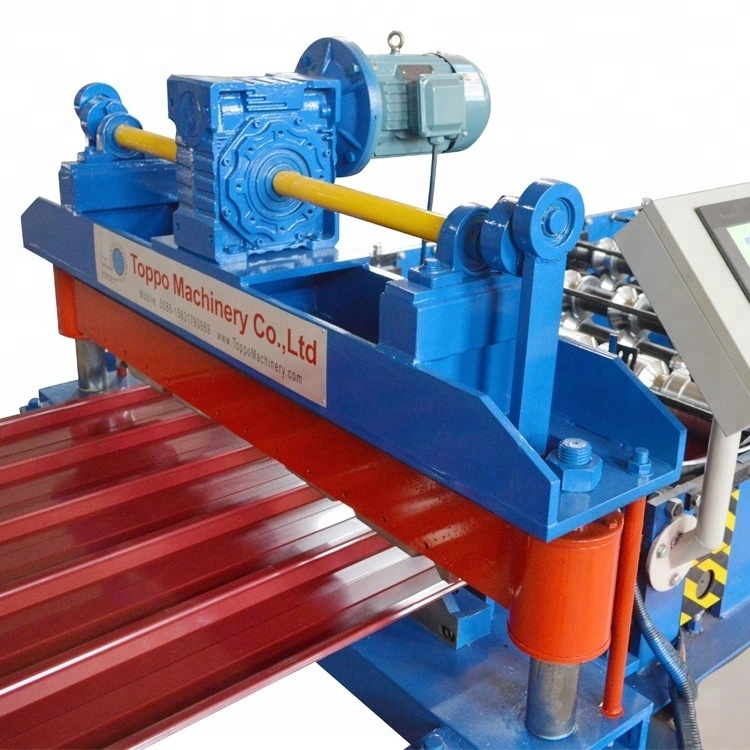

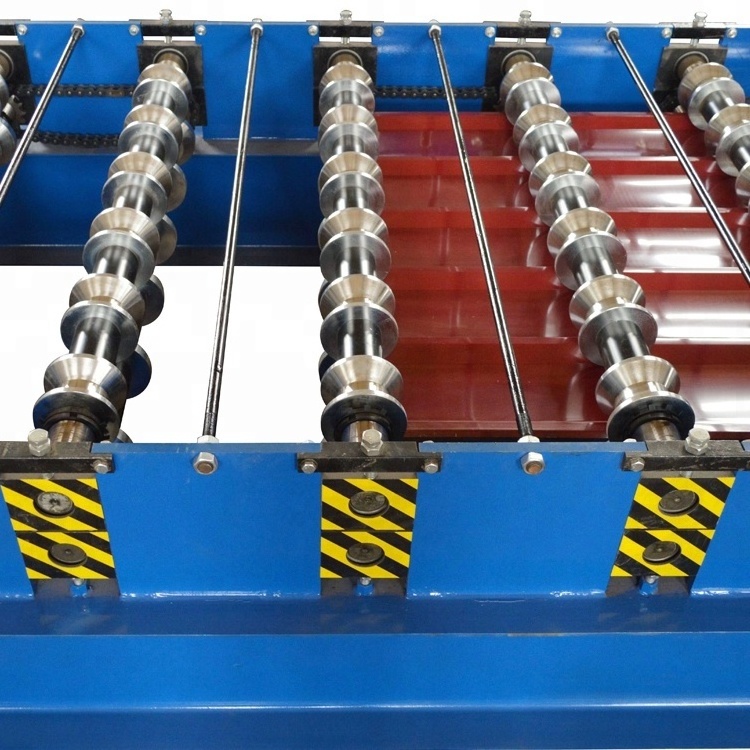

| Product Description |

|

Name |

High Quality Zinc Roofing Color Steel IBR Sheet Roll Forming Machine |

|

Suitable Material |

Colored or galvanized steel coil, HRB60 or equivalent |

|

Thickness Range |

0.3-0.8 mm |

|

Coil Width Range |

914, 1000, 1220 or 1250 mm. According to your actual drawing. |

|

Electric Power |

380V, 50 Hz, 3 phase or according to your need. |

|

Dimension |

About 7.2*1.3*1.1m(L*W*H), as per the drawing |

|

Cutting |

Automatically stop and cutting when it comes to the set length. |

|

Length of the Sheet |

You can set the length according to your need. It is controlled by PLC length accuracy: ±1mm. |

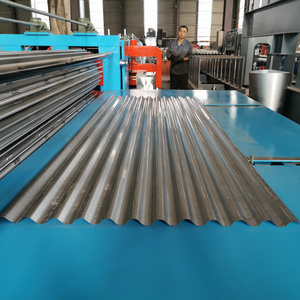

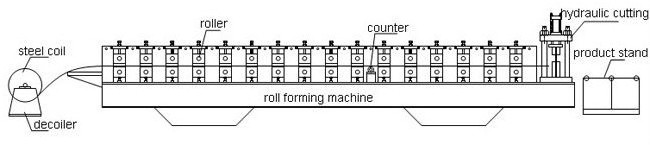

Working Flow

Decoiling-Sheet guiding-Roll forming-Measure length-Cutting-Panels to product stand

For more details, please contact us to help you learn more about our products

—

—

Details Show

—

—

—— Product Details ——

|

|

||||||||||

|

|

|||||||

|

|||||||

|

|||||||

|

|

||||||

why choose us

| Product Applications |

The advantage of IBR sheet includes beautiful, classical appearance and grace taste.

It can be widely used in village, hotel, exhibition, vacation village, family construction and outdoor decorating.

| Shop hot products |

|

Packaging&Shipping |

a . Need one 20 or 40 ft container, according to your final drawing.

b . The main body of machine is fixed to container by 8mm diameter steel wire, rollers and shaft is

covered with anti-rust oil.

c . Spare parts in carton box.

| About Us |

Toppo Machinery starts roll forming machine since 1998.

We know well the requirements for the customers from different countries and have an outstanding export teams who will take care of your requests. Our experts and skilled workers complete the work with great precision.

We provide an extensive line of products , including roof and wall panel machine, tile roof machine, purlin forming machine, shutter door machine, floor decking machine and other associated equipment.

Our products have been sold worldwide over 90 countries including America, the UK, Australia, India, Sri Lanka South Africa, Tanzania, Nigeria etc.

|

FAQ |

1. what is your guarantee period?

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.?

You can also come to our factory to check the machine and learn how to operate before shipping. It only needs 2 hours and you can operate well.

3. I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

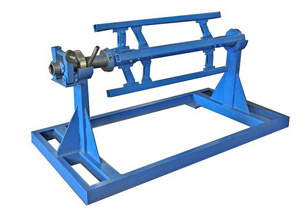

4. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes a manual decoiler, roll forming machine and product stand. when you get the machine in your factory, you just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.