- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

FORWARD

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

8500*1000*1200

-

Weight:

-

2.5 kg

-

Product name:

-

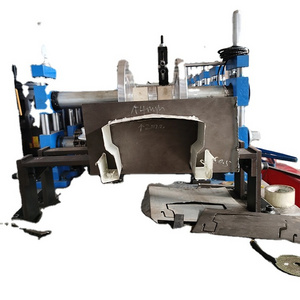

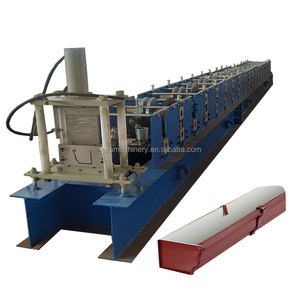

CE Approved Automatic Rain Gutter Roll Making Machine

-

Under Frame:

-

400H-beam

-

Forming Step:

-

16 Steps

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

45# Steel Outer Diameter: 75mm

-

Driving Motor:

-

4KW with Shanghai Brand

-

Transmission Chain:

-

1 inch with Hangzhou Brand

-

Cutting blade material:

-

Cr 12Mov processing

-

Usage:

-

Water gutter,rain gutter on roof and wall

-

Certification:

-

CE/ISO9001

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

FORWARD

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

8500*1000*1200

-

Weight:

-

2.5 kg

-

Product name:

-

CE Approved Automatic Rain Gutter Roll Making Machine

-

Under Frame:

-

400H-beam

-

Forming Step:

-

16 Steps

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

45# Steel Outer Diameter: 75mm

-

Driving Motor:

-

4KW with Shanghai Brand

-

Transmission Chain:

-

1 inch with Hangzhou Brand

-

Cutting blade material:

-

Cr 12Mov processing

-

Usage:

-

Water gutter,rain gutter on roof and wall

-

Certification:

-

CE/ISO9001

High Quality Color Steel Rain Gutter Water Gutter Roll Forming Making Machinery

|

High Quality Color Steel Rain Gutter Water Gutter Roll Forming Making Machinery |

||

|

1 |

Suitable raw material |

PPGI/PPGL/GI/GL Steel Coils |

|

2 |

Thickness of coil sheet |

0.3-0.6mm |

|

3 |

Feeding Coil width |

430mm |

|

4 |

Effective width |

203.2mm |

|

5 |

Under frame |

400H-beam |

|

6 |

Diameter of Soild shaft |

70mm, high grade 45# steel,with keyway |

|

7 |

Roller |

45# steel hard chrome coated 0.05-0.07mm |

|

8 |

Thickness of middle plate |

18mm |

|

9 |

Forming stations |

16 |

|

10 |

Drive type |

By chain(1.0 inch) link bearing model 6210 |

|

11 |

Power of main motor |

3kw with Cycloidal reducer, Lichao, Shanghai |

|

12 |

Power of pump station |

3kw, Lichao, Shanghai |

|

13 |

Forming speed |

About 15-20m/min |

|

14 |

Hydraulic cutting |

Controlled by PLC |

|

15 |

PLC |

DELTA, TAIWAN / Mitsubishi, Japan |

|

16 |

Material of cutting blade |

Cr12Mov, quenching 58-62℃ |