- Product Details

- {{item.text}}

Quick Details

-

Thickness:

-

5mm-300mm Customized

-

Size:

-

Customized

-

name:

-

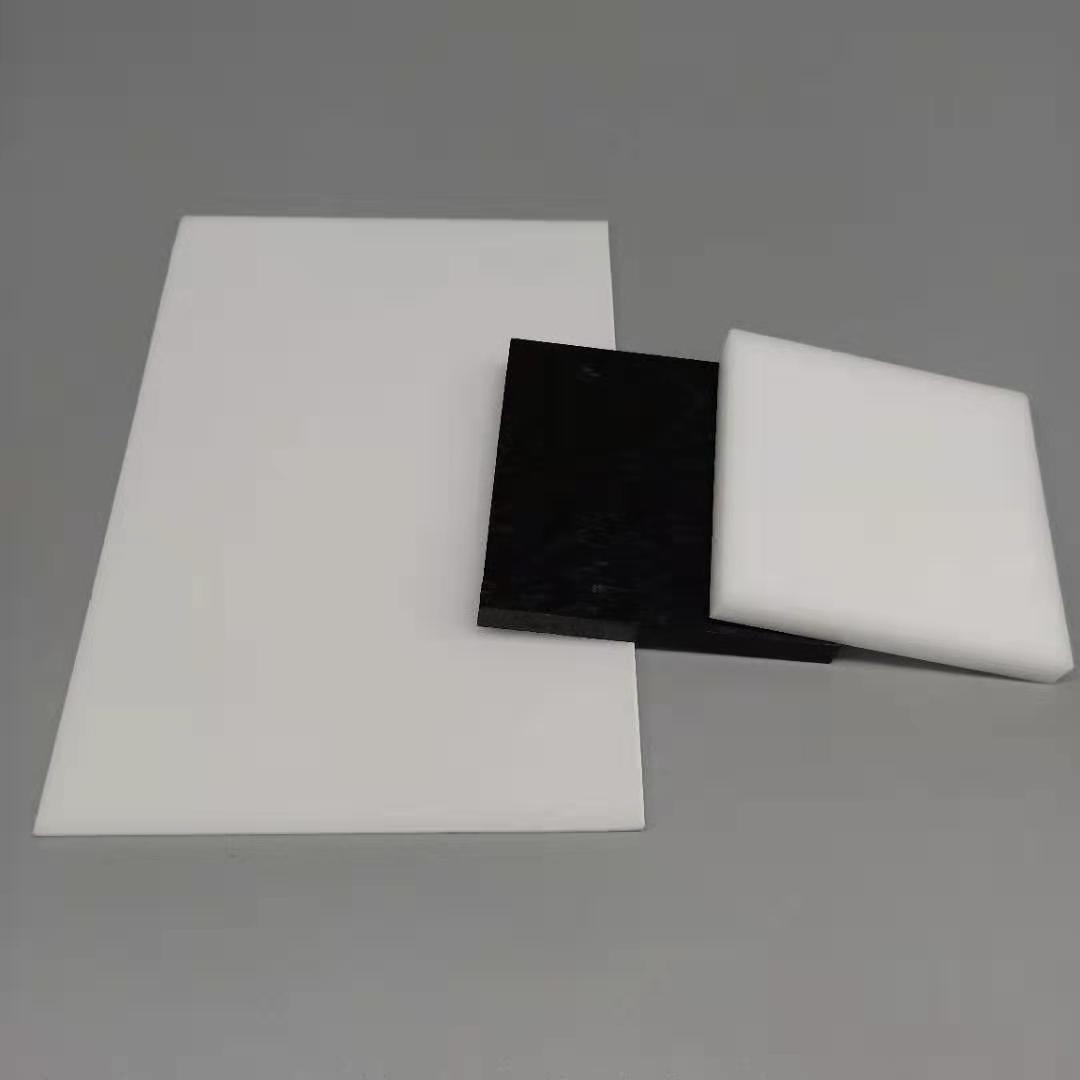

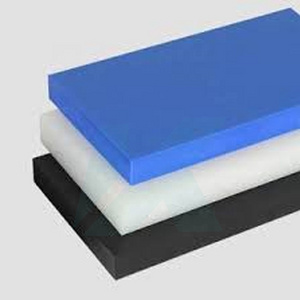

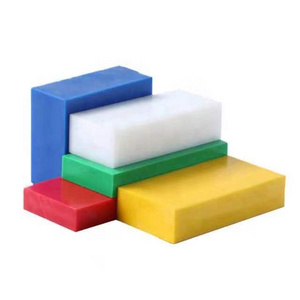

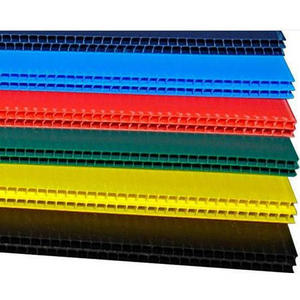

polypropylene sheet HDPE block UHMW-PE boards PP cutting board

-

Specifications (size):

-

Custom Size

-

Color:

-

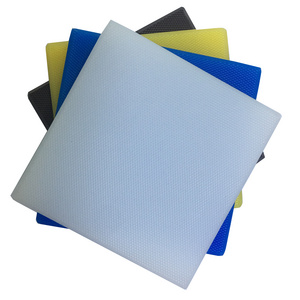

Natural,White, Blue, Black, other colors

-

Density:

-

0.94-1.15g/cm3

-

Free Sample:

-

Yes

-

Available Service:

-

CNC Cutting and Machining

-

Shape:

-

Sheet & Rod

-

Application:

-

chemical machinery/anti-corros

-

Feature:

-

High impact and notch impact strength

-

Melting point:

-

220℃

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HongYue

-

Model Number:

-

Board

-

Thickness:

-

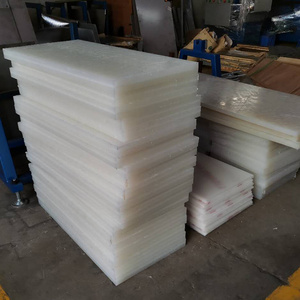

5mm-300mm Customized

-

Size:

-

Customized

-

name:

-

polypropylene sheet HDPE block UHMW-PE boards PP cutting board

-

Specifications (size):

-

Custom Size

-

Color:

-

Natural,White, Blue, Black, other colors

-

Density:

-

0.94-1.15g/cm3

-

Free Sample:

-

Yes

-

Available Service:

-

CNC Cutting and Machining

-

Shape:

-

Sheet & Rod

-

Application:

-

chemical machinery/anti-corros

-

Feature:

-

High impact and notch impact strength

-

Melting point:

-

220℃

At present, there are mainly the following types of extruded nylon sheets commonly used in the market:

1: Nylon 6 (White): This material has the most superior overall properties, including mechanical strength, stiffness, toughness, mechanical shock absorption and wear resistance. These properties, combined with good electrical insulation and chemical resistance, make nylon 6 a "universal grade" material for the manufacture of mechanical structural parts and maintainable parts.

2: Nylon 66 (cream): Compared with nylon 6, it has better mechanical strength, stiffness, heat resistance and wear resistance, and better creep resistance, but the impact strength and mechanical shock absorption performance are degraded, which is very suitable for automatic lathes. Machining.

3: Nylon 4.6 (reddish brown): Compared with ordinary nylon, nylon 4.6 is characterized by strong storage stability, good creep resistance, and heat aging over a wide temperature range. Therefore, nylon 4.6 is used. Nylon 6, nylon 66, POM and PET in the "higher temperature range" (80 -150 °C) that does not meet the requirements for stiffness, creep resistance, heat aging, fatigue strength and wear resistance

4: Nylon 66+GF30 (black): Compared with pure nylon 66, this nylon is filled with 30% glass fiber reinforced, heat resistance, strength and rigidity. It has improved creep resistance, dimensional stability, and wear resistance, and its maximum allowable temperature is high.

5: Nylon 66+MOS2 (gray black): This nylon is filled with molybdenum disulfide. Compared with nylon 66, its rigidity, hardness and dimensional stability are improved, but the impact strength is reduced. Molybdenum disulfide The grain formation effect improves the crystal structure and improves the material bearing and wear resistance.

Main characteristics

Good aging resistance, good mechanical damping capacity, good slidability, excellent wear resistance, good machinability, good precision control, no creep, good anti-wear performance and good dimensional stability.

Anti-corrosion equipment for gears and parts of bad materials. Wear parts, transmission structural parts, household appliance parts, automobile manufacturing parts, screw rods to prevent mechanical parts, chemical machinery parts, chemical equipment, etc.

|

name

|

polypropylene sheet HDPE block UHMW-PE boards PP cutting board

|

|

Specifications (size)

|

According to your request

|

|

Color

|

Natrual, Blue, Ivory, Black

|

|

Density

|

0.94-1.15g/cm3

|

|

Free Samples

|

Yes

|

|

Shape

|

Sheet ,Rod,plate,panel,slab,board,round

|