- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Propellent

-

Liquid Flow Rate:

-

Variable

-

Maximum Working Pressure:

-

4.5Mpa

-

Weight:

-

20KGs

-

Dimension(L*W*H):

-

525*111*252mm

-

Working Temperature Range:

-

-30~225℃

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support

-

Material:

-

Stain Steel 316

-

Application:

-

Evaporator, Condenser

-

Design Pressure:

-

1.2MPa~4.5MPa

-

Design Temperature:

-

-195~225

-

Plate thickness:

-

0.4mm~1.0mm

-

Packing:

-

Woodern Box

-

Welded material:

-

Copper, Nickel

-

Type:

-

plate heat exchanger

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

CE

Quick Details

-

Structure:

-

Plate Heat Exchanger

-

Voltage:

-

220v/380v/customized

-

Core Components:

-

plate

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Propellent

-

Liquid Flow Rate:

-

Variable

-

Maximum Working Pressure:

-

4.5Mpa

-

Weight:

-

20KGs

-

Dimension(L*W*H):

-

525*111*252mm

-

Working Temperature Range:

-

-30~225℃

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support

-

Material:

-

Stain Steel 316

-

Application:

-

Evaporator, Condenser

-

Design Pressure:

-

1.2MPa~4.5MPa

-

Design Temperature:

-

-195~225

-

Plate thickness:

-

0.4mm~1.0mm

-

Packing:

-

Woodern Box

-

Welded material:

-

Copper, Nickel

-

Type:

-

plate heat exchanger

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

CE

Product Description

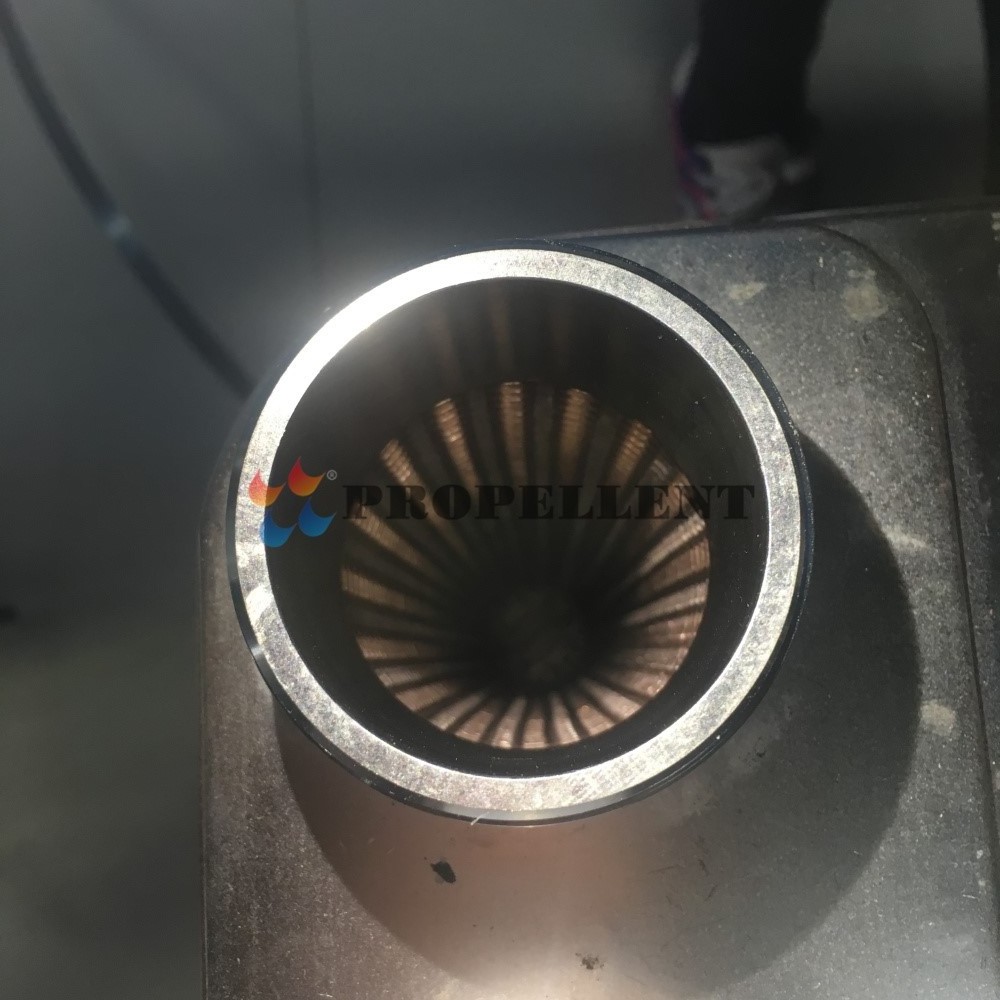

Brazed plate heat exchanger is composed of a lot of stainless steel plates and front and rear covers, it is separated copper sheet

(or nickel) with high purity and brazed in high temperature furnace. In order to achieve the best heat transfer effect, All

corrugated plates will be combined with velocity heat transfer plate with high, middle and low level according to the clients'

requirements. It has a compact structure without gasket and outer frame to operate in the condition of high temperature and high

pressure.

|

Model

|

PLB3-055

|

|

Size: H*W

|

525*111mm

|

|

Brand

|

Propellent

|

|

place of origin

|

Shandong

|

|

Plate material

|

Stainless steel

|

|

welded material

|

Copper, Nickel

|

-

1.High energy efficiency-low operating cost

2.Flexible configuration-heat transfer area canbe modified

3.Easy to install-compact design

4.High serviceability-easy to open for inspection and cleaning and easy to clean by CIP

5.Every detail is carefully designed to ensure optimal performance,maximum uptime and easy maintenance

6.Light weight, small footprint, easy installation

Detailed Images

Related Products

Packing&Shipping

Company Introduction

Propellent, is the Booster and leader of effective heat exchange technology in all industries.

Propellent can be able to offer a full range of heat exchange design calculation in full working condition. We have accumulated

rich experience in heating, cooling and waste heat recovery for complex process mediums. Propellent never views separately in the

selection of heat exchange equipment applications, but put it in the whole process production line, Therefore, we find the best

balance to consider the whole initial investment in equipment and long-term operating costs. We optimize manufacturing processes

of our clients and reduce the use of fresh energy to provide our customers maximum value when we find reasonable main points in

high heat transfer efficiency and pressure loss.

Propellent can be able to offer a full range of heat exchange design calculation in full working condition. We have accumulated

rich experience in heating, cooling and waste heat recovery for complex process mediums. Propellent never views separately in the

selection of heat exchange equipment applications, but put it in the whole process production line, Therefore, we find the best

balance to consider the whole initial investment in equipment and long-term operating costs. We optimize manufacturing processes

of our clients and reduce the use of fresh energy to provide our customers maximum value when we find reasonable main points in

high heat transfer efficiency and pressure loss.

Our Services & Strength

1. We seek an understanding of the working conditions for you, and carries on the effective communication with your engineer, to make a perfect solution.It will be more accurate, reducing purchase cost and energy consumption.

2. Our technical engineers can according to user's working conditions, for our customers to provide professional selection plan and drawings, and we will choose the appropriate solutions, to provide a stable, efficient service for you.

3. We will give more consideration to customers' working conditions in order to reduce their equipment purchasing cost and energy consumption of processing operations (water, electricity and gas)

2. Our technical engineers can according to user's working conditions, for our customers to provide professional selection plan and drawings, and we will choose the appropriate solutions, to provide a stable, efficient service for you.

3. We will give more consideration to customers' working conditions in order to reduce their equipment purchasing cost and energy consumption of processing operations (water, electricity and gas)

FAQ

1. Are you factory?

Yes,we are one of the largestheat exchanger manufactory in China

2. Are there any discount for the heat exchangers?

Yes. Bigger quantity will enjoy lower discount!

3. What information needed if I want a quotation?

Please advise us the Type of heat exchangers, Material , Heat Exchanger Capacity, Heat Transfer Area, Liquid Flow and Temperature in and out , Quantity, or any requirements in size.

4. What is the MOQ?

We accept loose quantity order,mixed order,any trial orders.

5. When can I get the price?

We usually quote within 2 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Hot Searches