- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SR-SP20

-

Model:

-

SR-SP20

-

Capacity:

-

22000pcs/H (20pin)

-

Cutting length:

-

55-850mm customized

-

Stripping length:

-

A side 0-7mm, B side 0-9mm

-

Applicable wires:

-

OD 0.8-2.0mm

-

Maximum cable width:

-

20mm

-

Maximum cable pin:

-

20pin

Quick Details

-

Usage:

-

Crimping

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sinrad

-

Model Number:

-

SR-SP20

-

Model:

-

SR-SP20

-

Capacity:

-

22000pcs/H (20pin)

-

Cutting length:

-

55-850mm customized

-

Stripping length:

-

A side 0-7mm, B side 0-9mm

-

Applicable wires:

-

OD 0.8-2.0mm

-

Maximum cable width:

-

20mm

-

Maximum cable pin:

-

20pin

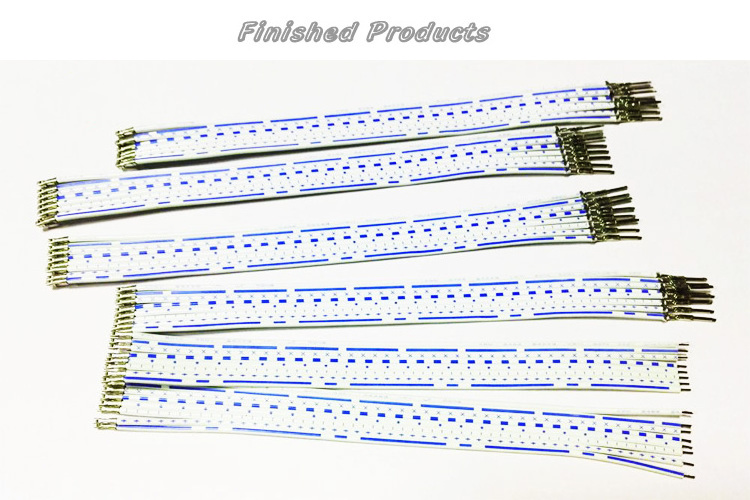

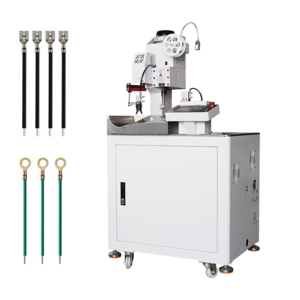

Product Description

Specification

|

Function

|

Ribbon wire Cutting stripping crimping

|

|

Power

|

4000W

|

|

Air

|

0.4-0.6MPa( Clean and dry)

|

|

Wire type

|

AWG28-18,ribbon wire,electrical wire

|

|

Efficiency

|

22000pcs/h(ribbon wire 20pin)

|

|

mold replacement

|

Adjustment

|

|

cutting length

|

50-850mm(customized)

|

|

stripping length

|

A side 0-7mm, B side 0-9mm

|

|

Applicable wires

|

OD 0.8-2.0mm

|

|

Maximum cable width

|

20mm

|

|

Maximum cable pin

|

20PIN

|

|

Size

|

L1800*W1400*H1550mm

|

|

Weight

|

450KG

|

|

Voltage

|

AC220V 50HZ

|

|

Installation space

|

2000*3000mm

|

|

Working environment

|

level and strong ground, dry, without direct sunlight

|

|

Current Rating

|

15A

|

Features

1: This machine adopts

Japanese Panasonic control system

and

Panasonic servo

to achieve precision, high efficiency and stability.

2: Adjust by touch screen control , including: line length, stripping length, terminal position, etc., all touch screen adjustments; the entire operation process will be seen at a glance, and multiple devices can be operated by one person.

3: Product function:

2: Adjust by touch screen control , including: line length, stripping length, terminal position, etc., all touch screen adjustments; the entire operation process will be seen at a glance, and multiple devices can be operated by one person.

3: Product function:

Double-end crimping terminal; applied to the cable, the electronic wire can be processed on this device,without the need to replace accessories, only minor adjustments can be made, to achieve multi-purpose machine, reduce equipment investment.

4: Applicable terminal model , PH, XH, ZH, SCN, SM, VH, DuPont and other continuous terminal crimping.

5: Good stability, the use of eccentric shaft, balanced terminal pressure, neat pressing, high yield, cam transmission structure,control branching movement is stable and fast.

6: High efficiency , the pressing speed can reach 22000pcs H (max), the machine can work 24 hours.

7: Special function:

(1) 2pin cable can output 5pcs at the same time.

(2) The A and B ends are separated by positive and negative pressure ends, and the B end can be half or fully stripped.

(3) Steering crimping, two-end crimping, single-end crimping, interval crimping, positive and negative crimping, etc.

8: Commissioning: Commissioning is simple, with full servo control of wire delivery, branch length, cutting, and stripping.

4: Applicable terminal model , PH, XH, ZH, SCN, SM, VH, DuPont and other continuous terminal crimping.

5: Good stability, the use of eccentric shaft, balanced terminal pressure, neat pressing, high yield, cam transmission structure,control branching movement is stable and fast.

6: High efficiency , the pressing speed can reach 22000pcs H (max), the machine can work 24 hours.

7: Special function:

(1) 2pin cable can output 5pcs at the same time.

(2) The A and B ends are separated by positive and negative pressure ends, and the B end can be half or fully stripped.

(3) Steering crimping, two-end crimping, single-end crimping, interval crimping, positive and negative crimping, etc.

8: Commissioning: Commissioning is simple, with full servo control of wire delivery, branch length, cutting, and stripping.

Application

Custom automatic terminal machine

All kind of wire harness automatic crimping machine we can provide.

You just send you sample and contact us.

You just send you sample and contact us.

Packing & Delivery

All the machines are with safety packing. Small machines would be packed into a carton box.

Large machines would be wooden case package.

Large machines would be wooden case package.

Hot Searches