Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Board Size:

-

OEM Custom Design

-

Model Number:

-

led board

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

FS

-

Copper Thickness:

-

1/3oz ~6oz

-

Min. Hole Size:

-

0.1mm (4mil)

-

Min. Line Width:

-

1/2 oz. copper .003" +/- .0005" (0.0762mm)

-

Min. Line Spacing:

-

1/2 oz. copper .003" +/- .0005" (0.0762mm)

-

Surface Finishing:

-

HAL, HASL(LF), Immersion gold, Gold plating,

-

Layer No.:

-

1-32 Layers

-

Base, Cover film, Stiffeners thickness::

-

0.5mil, 1.0mil, 2.0mil, 3.0mil, 4.0mil, 5.0mil, 6.0mil,0.10um

-

BGA Ball Pitch:

-

1mm ~ 3mm(4mil ~ 12mil)

-

Hi-TG FR4 Material:

-

Tg-130 Tg-140 Tg-160 Tg-170

-

PCB Test:

-

Flying probe and AOI (Default)/Fixture Test

-

PCB Assembly Method:

-

SMT, Through-hole, Mixed, BGA

-

PCB Assembly Test:

-

Visual Inspection (default), AOI, FCT, X-RAY

-

Electrical Testing:

-

Net List Test, Flying Probe Test, Through Hole Test, Dual Access Test

-

Certificate Standard:

-

IPC-A-600H Class 2, Class 3, TS16949,,ROHS and as your need

-

Special requirements:

-

Buried and blind vias, Impedance control, via plug, BGA soldering etc.

Quick Details

-

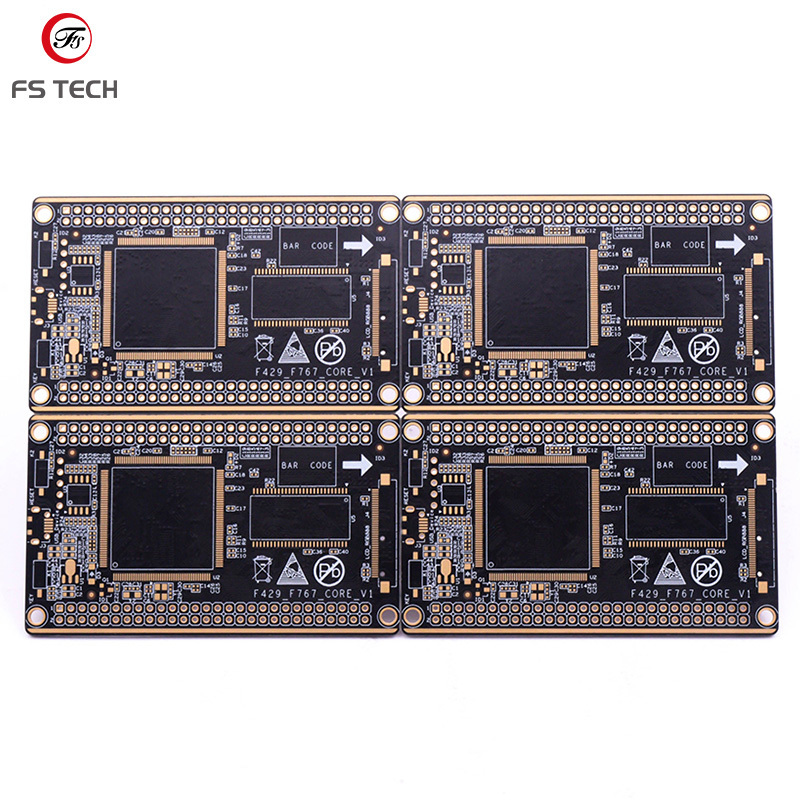

Number of Layers:

-

1-32 Layers

-

Base Material:

-

FR-4,Hi-TG FR4,CEM-1,CEM-3, TACONIC, Metal/

-

Board Thickness:

-

0.4-3.0mm

-

Board Size:

-

OEM Custom Design

-

Model Number:

-

led board

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

FS

-

Copper Thickness:

-

1/3oz ~6oz

-

Min. Hole Size:

-

0.1mm (4mil)

-

Min. Line Width:

-

1/2 oz. copper .003" +/- .0005" (0.0762mm)

-

Min. Line Spacing:

-

1/2 oz. copper .003" +/- .0005" (0.0762mm)

-

Surface Finishing:

-

HAL, HASL(LF), Immersion gold, Gold plating,

-

Layer No.:

-

1-32 Layers

-

Base, Cover film, Stiffeners thickness::

-

0.5mil, 1.0mil, 2.0mil, 3.0mil, 4.0mil, 5.0mil, 6.0mil,0.10um

-

BGA Ball Pitch:

-

1mm ~ 3mm(4mil ~ 12mil)

-

Hi-TG FR4 Material:

-

Tg-130 Tg-140 Tg-160 Tg-170

-

PCB Test:

-

Flying probe and AOI (Default)/Fixture Test

-

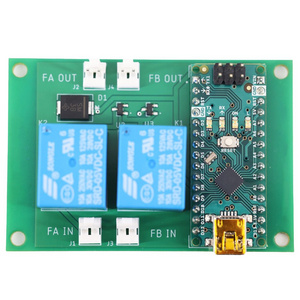

PCB Assembly Method:

-

SMT, Through-hole, Mixed, BGA

-

PCB Assembly Test:

-

Visual Inspection (default), AOI, FCT, X-RAY

-

Electrical Testing:

-

Net List Test, Flying Probe Test, Through Hole Test, Dual Access Test

-

Certificate Standard:

-

IPC-A-600H Class 2, Class 3, TS16949,,ROHS and as your need

-

Special requirements:

-

Buried and blind vias, Impedance control, via plug, BGA soldering etc.

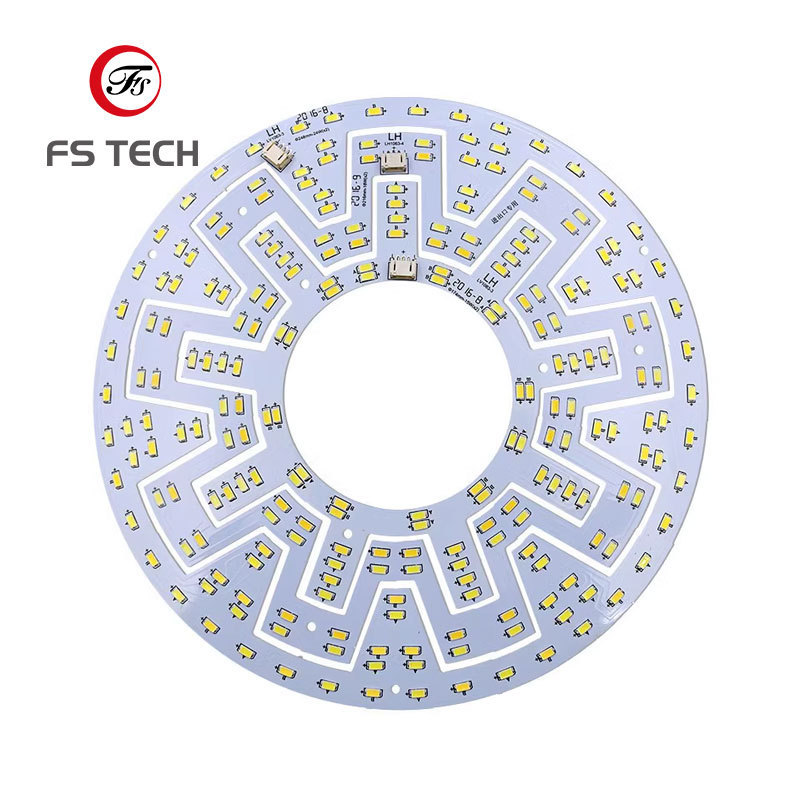

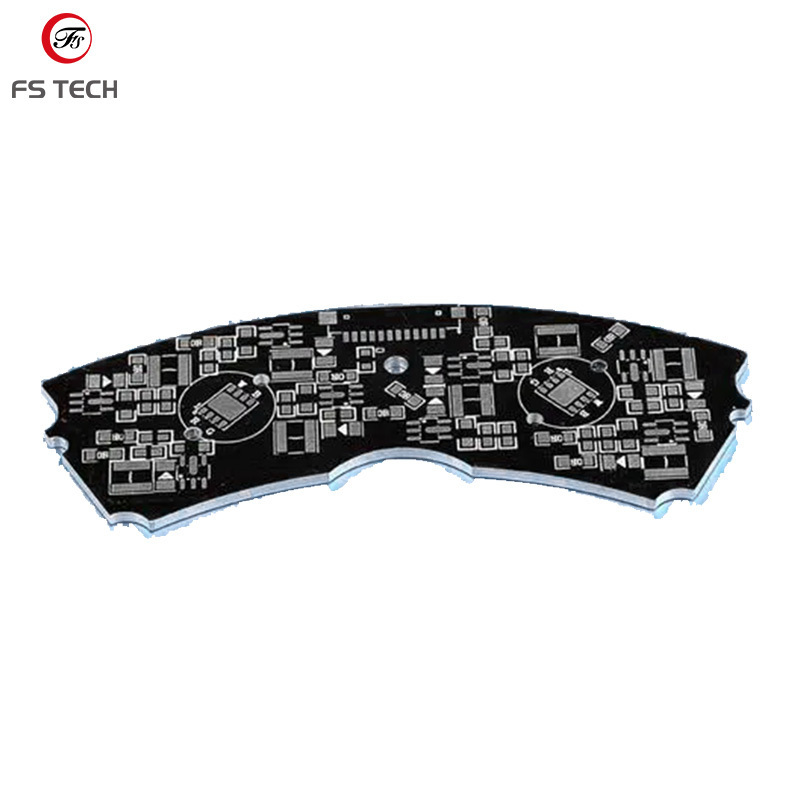

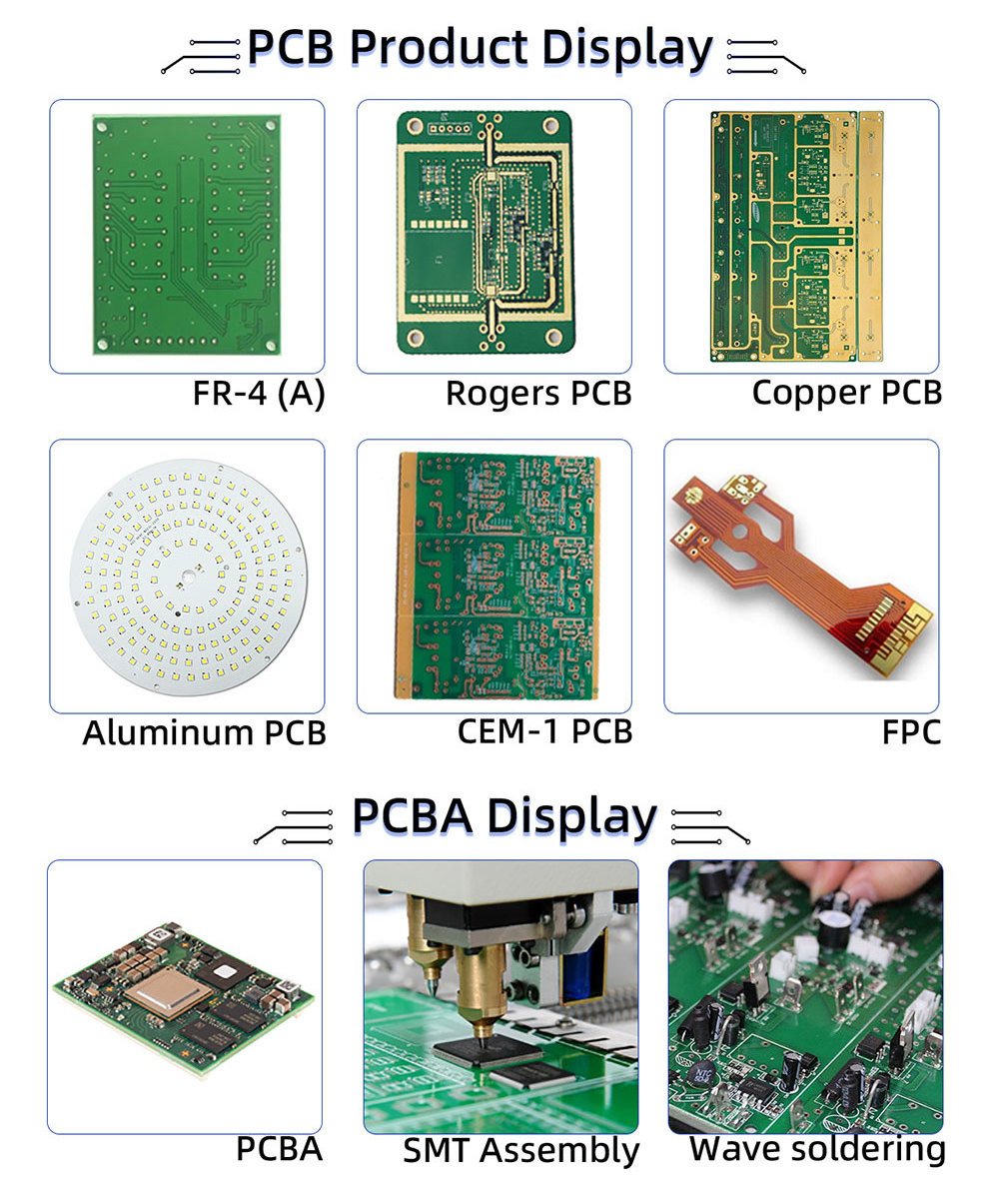

Aluminum PCB Board Manufacturer

Shenzhen FS Technology Co., Ltd. is located in Shenzhen, the city of science and technology in China.

FS Technology is a PCB/PCBA manufacturing and sales integrated industry and trade enterprise.

Our customers are located in different countries and regions all over the world. We have more than 18 years of experience in PCB/PCBA industry.

FS Technology serves each customer professionally with over 18 years of experience.

All you need to do is send an inquiry and provide your production file. Our PCB/PCBA customer service provide you with professional service.

Quick quotation and sample arrang for you within 24 hours. We look forward to your inquiry for our further talk

Click Into VR To Visit Our Factory

|

PCB Capacity

|

|

|

|

|

|

|

|

Item

|

Capacity

|

|

|

Layer

|

1-32 Layer

|

|

|

PCB Base Material

|

FR-4 / Rogers / H-tg / Aluminum / CEM-1 / FPC

|

|

|

Max PCB size

|

850mmX570mm

|

|

|

Dimensional accuracy

|

±0.13mm

|

|

|

Board Thickness

|

0.4-3.0mm

|

|

|

PCB thickness tolerance

|

(THK ≥0.8mm) ±8%

|

|

|

|

(THK <0.8mm) ±10%

|

|

|

Minimum line width

|

0.09/0.09mm(3.5mil/3.5mil)

|

|

|

Minimum line distance

|

0.09/0.09mm(3.5mil/3.5mil)

|

|

|

Outer copper thickness

|

Double layer(1OZ,2OZ,3OZ,4OZ, 5OZ)

Multi-layer(1OZ,2OZ) |

|

|

Inner copper thickness

|

0.5OZ,1OZ,2OZ

|

|

|

Hole Size (mechanical

|

0.3~6.3mm

|

|

|

Hole Tolerance (mechanical

|

± 0.075mm

|

|

|

Impedance tolerance

|

± 10%

|

|

|

Solder mask color

|

Green.Black.Red.Yellow.White.Blue.Purple.Matte Gre

|

|

|

Surface Finishing

|

HASL/OSP/ENIG/IMS/IMT

|

|

|

PCB test

|

X-ray/100% AOI Testing/ICT/FCT Test/E-Test

|

|

|

File type

|

Gerber: BOM:

|

|

|

PCBA Capacity

|

|

|

|

|

|

|

|

item

|

Capacity

|

|

|

SMT Line

|

5 Line

|

|

|

SMT capacity

|

8 Million Placements Per Day

|

|

|

Wave soldering

|

2 Line

|

|

|

Wave Soldering Capacity

|

2 Million Placements Per Day

|

|

|

Board type

|

PCB / FPC / Aluminum PCB

|

|

|

Welding type

|

Single-sided and double-sided welding

|

|

|

Max. PCB size

|

680*550mm Smallest:0.25"*0.25"

|

|

|

Min. component

|

0201-54 sq.mm (0.084 sq.inch),Long Connector,CSP,BGA,QFP

|

|

|

Min. IC pitch

|

0.35mm

|

|

|

BGA ball pitch

|

0.4mm

|

|

|

Reflow soldering temperature

|

245℃

|

|

|

Soldering type

|

Lead free reflow soldering/wave soldering (RoHS standard)

|

|

|

QC Test

|

AOI / Xray / ICT / FCT / E-test

|

|

|

Other process

|

PCBA assembly / IC Programming / Functional Testing

|

|

FAQ

1. What service do you have

We provide Tunrkey PCB/PCBA service including R&D, PCB design, PCB manufacturing, SMT assembly, Component procurement, Functional testing, etc.

2.

What is needed for PCB/PCBA quotation?

For PCB empty board project:

please provide Gerber file. And in mark the PCB material type, color, copper thickness, PCB thickness. Order quantity, Our sales engineer will offer you the best price based on this information.

For PCBA project:

please provide

Gerber file and BOM

and order quantity with the above PCB basic information. Our sales engineer will offer you the best price.

3.

Are my files safe?

Sure. Your files we use only for the production arrangement. Everything is only within our company. We will not share your files with anyone else. We are willing to sign an NDA contract so that your files are always secure.

4.

What is the mini order quantity(MOQ) that you can accept?

FS Tech has no MOQ request. We accept any quantity of small orders or 1pcs prototype sample.

5. How to calculate shipping cost?

The shipping cost is based on the total weight and volume of the goods. Please let us know your address and delivery term. We will arrange the best delivery and transportation for you.

6.

Can we check quality control during production?

Sure. We are open and sharing our production process with you. We welcome you to visit our factory and production process.

7. What is your testing process? How to control product quality?

For PCB project: We will conduct flying needle testing and electronic testing. Ensure 100% pass quality inspection.

For PCBA project: FAI testing is conducted before production begins, AOI testing and X-Ray testing are conducted during production, and finally functional testing is conducted according to customer requests. Ensure 100% pass quality testing.

Hot Searches