- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Power:

-

2.2 KW

-

Dimension(L*W*H):

-

1200wih x 1700dx 3200 h

-

Weight (KG):

-

1500

-

Model:

-

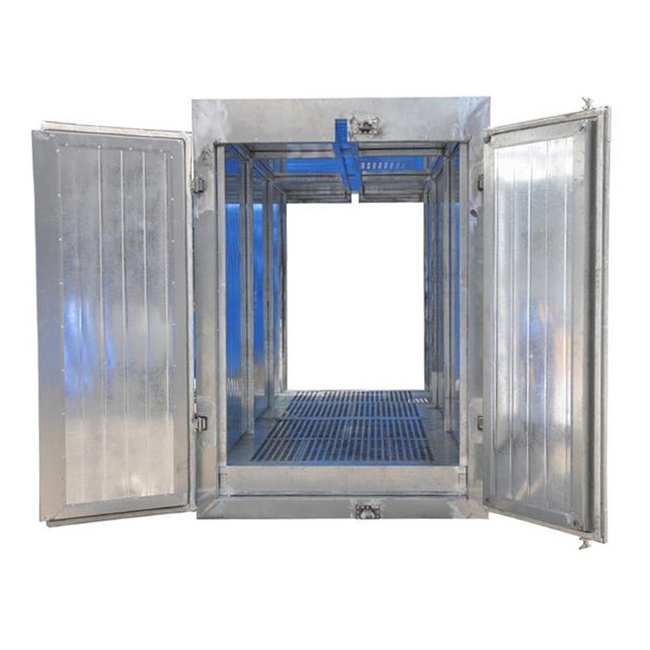

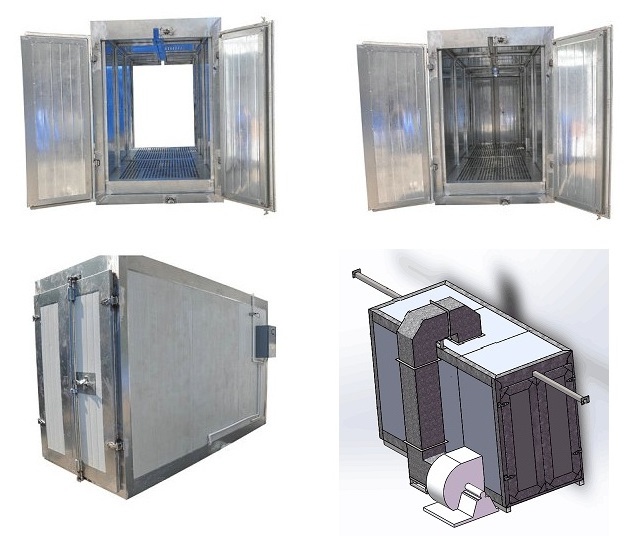

Kafan-2447

-

Worksize Dimensions:

-

1200Width x 1700 Height x3200 Depth

-

Overall Dimensions:

-

1407 Width x 2203 Height x 3424Depth

-

Power Supply:

-

Electric/ 40kw

-

Voltage/Frequency:

-

As Required

-

Warm-up Time:

-

15-30 min. (180° C)

-

Temperature Stability:

-

< ± 3-5°C

-

Ventilation Performance:

-

805-1677m3/h

-

Transportation:

-

Trolley On Top

Quick Details

-

Machine Type:

-

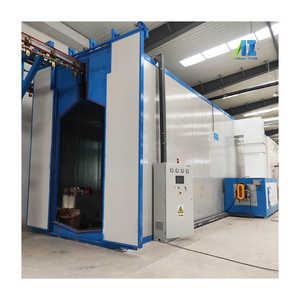

powder paint oven, Curing oven

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

kAFAN

-

Voltage:

-

380V/220V

-

Power:

-

2.2 KW

-

Dimension(L*W*H):

-

1200wih x 1700dx 3200 h

-

Weight (KG):

-

1500

-

Model:

-

Kafan-2447

-

Worksize Dimensions:

-

1200Width x 1700 Height x3200 Depth

-

Overall Dimensions:

-

1407 Width x 2203 Height x 3424Depth

-

Power Supply:

-

Electric/ 40kw

-

Voltage/Frequency:

-

As Required

-

Warm-up Time:

-

15-30 min. (180° C)

-

Temperature Stability:

-

< ± 3-5°C

-

Ventilation Performance:

-

805-1677m3/h

-

Transportation:

-

Trolley On Top

Introduction to coating equipment heating system:

The heating system is an important part of the production line curing product, which directly affects the heating temperature of the oven. At present, the most common heating methods in the coating industry can be divided into the following types:

1.

Gas heating system

: burning natural gas / bottle of liquefied gas is characterized by relatively no pollution to the product after burning, relatively low input cost, rapid heating, and is currently one of the most widely used heating methods;

2.

Bio-particle heating system

: The characteristics of burning bio-waste are to reuse bio-waste, the use cost is relatively low but the input cost is relatively high and the environment has certain pollution;

3.

Electric heating system

: It is energized and heated by heating wire or heating pipe. Its characteristics are economical, environmentally friendly and pollution-free. It is also one of the most popular heating methods.

4.

Coal-fired / diesel heating system

: At present, the application of this heating system is relatively less, which is mainly caused by environmental pollution;

Automatic controls-simple PLC system

The material is rock wool board

|

SPECIFICATIONS FOR Energy-Saving Liquefied/Natural Gas/ Diesel Used Powder Coating Curing Oven

|

|

|

|

|||

|

Kafan-2447 Energy-Saving Liquefied/Natural Gas/ Diesel Used Powder Coating Curing Oven

|

Model

|

Kafan-2447

|

|

|||

|

|

Worksize Dimensions

|

W1200 x D1700 x H3200 (mm)

|

|

|||

|

|

Circulation/ Air flow

|

Vertical ,Variable through holes on the walls

|

|

|||

|

|

Voltage/Frequency

|

As required

|

|

|||

|

|

Warm-up Time

|

15-30 Min. (180° C)

|

|

|||

|

|

Temperature Stability

|

< ± 3.0-5°C

|

|

|||

|

|

Temperature Max.

|

250° C

|

|

|||

|

|

Color

|

Can Be Customized

|

|

|||

|

|

Power Supply

|

Electric/ 40kw

|

|

|||

|

|

Motor Power

|

2.2KW

|

|

|||

|

|

Transportation

|

Trolley on top

|

|

|||

|

|

Warranty

|

12 months

|

|

|||

Advantage of Powder Coating and Steel Substrates Powder Paint Oven

2. Automatic control of working hours, automatic alarm at regular intervals

3. Hot air circulation, uniform temperature

4. With adjustable air outlet, exhaust port

5. Good thermal insulation performance, solid structure and beautiful appearance

Paint Powder In Booth

Workpiece Into The Oven

Roasted Workpiece

|

Packaging

|

|

|

|

Size

|

W2300 x D5000 x H4400 (mm)

|

|

|

Weight

|

1500 KG

|

|

|

Packaging Details

|

Wrap first with foam and then pack it in wooden boxes.

|

|