- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0.12

-

Weight:

-

120 KG

-

product name:

-

molecular distillation machine

-

Effective evaporation area (m2)::

-

0.2

-

Total Feed rate(L/h):

-

0-30L

-

Application:

-

essential oil/crude oil distillation

-

vacuum degree:

-

10Pa

-

Fram material::

-

SUS304

-

Working Temperature Range (°C):

-

Room temperature -200

-

motor power:

-

0.09kw

-

Wechat/WhatsApp:

-

+86-15901881353

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Juyuan

-

Voltage:

-

220V 380V 460V

-

Power:

-

0.12

-

Weight:

-

120 KG

-

product name:

-

molecular distillation machine

-

Effective evaporation area (m2)::

-

0.2

-

Total Feed rate(L/h):

-

0-30L

-

Application:

-

essential oil/crude oil distillation

-

vacuum degree:

-

10Pa

-

Fram material::

-

SUS304

-

Working Temperature Range (°C):

-

Room temperature -200

-

motor power:

-

0.09kw

-

Wechat/WhatsApp:

-

+86-15901881353

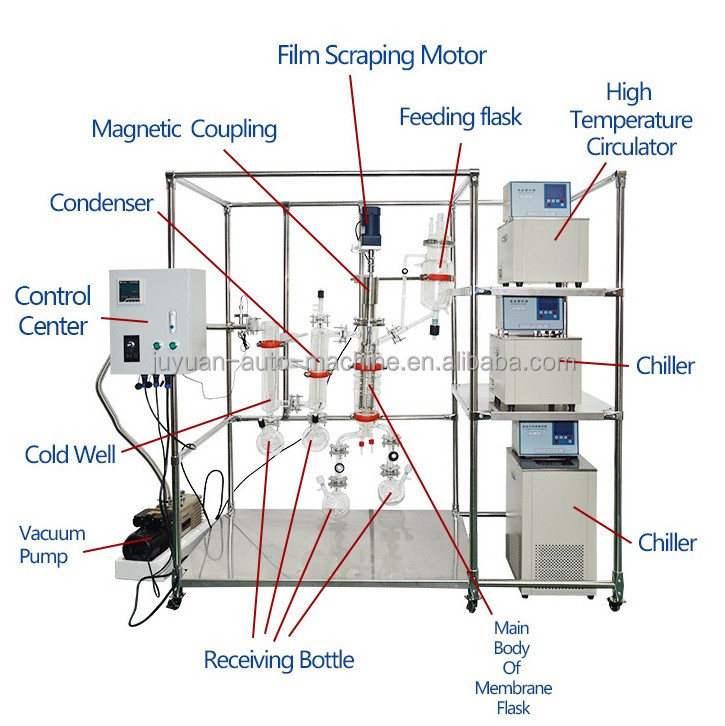

High quality Stainless steel wiped film molecular distillation system for crude oil

1. Equipment introduction:

A complete set of molecular distillation extraction equipment mainly includes: molecular evaporator, degassing system, feed system, heating system, cooling vacuum system and control system.

2. Equipment composition:

Cylindrical cylinder with heating jacket, rotor and built-in condenser; the fixed frame of the rotor is precisely equipped with a film wiper and an anti-splash device. The built-in condenser is located in the center of the evaporator, and the rotor rotates between the cylindrical barrel and the condenser. The short-path distiller consists of an externally heated vertical cylinder, its central condenser and a film wiper rotating between the distiller and the condenser.

|

Machine Name |

Main Specification |

|

Molecular distillation and extraction equipment Model:JY-FZ

|

1) Preheater: heat exchange area 0.2sqm; 2) Short-range evaporator: including main tank, built-in cooling core 0.6 sqm , heating oil jacket; specification 0.3sqm ; 3) Membrane scraper: Force the material into a membrane, and the membrane material: PTFE; 4) Magnetic seal and magnetic drive: magnetic seal and magnetic drive; 5) Condenser: heat exchange area of 0.6 square meters; 6) Light component buffer tank: 2L volume with sight glass; 7) Heavy component buffer tank: 2L volume with sight glass; 8) Vacuum buffer tank: 5L in volume. |

Configuration List

|

No. |

Name |

Brand |

Specification |

Quantity (pcs) |

|

1 |

Film Forming main device |

YN |

Φ200mm |

1 |

|

2 |

Condenser |

YN |

Serpentine |

1 |

|

3 |

Cool Well |

YN |

Dry ice type |

1 |

|

4 |

Feeding Flask

|

YN |

2L |

1 |

|

5 |

Receiving Flask |

YN |

3L |

2 |

|

6 |

Rotor motor |

Taiwan Motor |

450r/min |

1 |

|

7 |

Coupling Device |

YN |

Full closed |

1 |

|

8 |

Scraper device |

YN |

|

1 |

|

9 |

Scraper rotor |

YN |

Tetrafluoroethylene |

3 |

|

10 |

Vacuum Gauge device |

YN |

|

1 |

3.Technical parameters:

A first-stage molecular distillation

1) Preheater: Coil type with a heat exchange area of 0.2sqm,

2) Short-range evaporator: including main tank, built-in cooling core 0.6 sqm , heating oil jacket; specification 0.3 sqm

3) Film scraper: Force the material into a film, and the film material: PTFE

4) Magnetic seal and magnetic drive: magnetic seal and magnetic drive

5) Condenser: Heat exchange area 0.6 sqm

6) Light component buffer tank: 2L volume with sight glass

7) Heavy component buffer tank: 2L volume with sight glass

8) Vacuum buffer tank: volume 5L

B power equipment

1Material in and out system

1) Feeding pump: including motor, pump head material 304, frequency conversion speed regulation; 5-30L/h, explosion-proof motor

2) Heavy-phase discharge pump: including motor, pump head material 304, frequency conversion speed regulation; 5-60L/h, explosion-proof motor

3) Light phase discharge pump: including motor, pump head material 304, frequency conversion speed regulation; 5-60L/h, explosion-proof motor

2. Drive

1) Motor + reducer: 0.09KW, explosion-proof motor

3. Vacuum system

1) Fore pump: 8L/S, explosion-proof motor

2) No-load vacuum <30pa

3) After-stage pump: ZJ70, explosion-proof motor

4. Heating system

1) Heater: temperature 30-250 ℃ , using heat transfer oil as medium, explosion-proof

C instrument automatic control system

1. Meter

1) Vacuum gauge: connection method, KF, with explosion-proof cover

2)Vacuum regulating valve: used to adjust the vacuum degree of the system or release the vacuum

3) Flowmeter: 0-30L, safety and explosion-proof type

2. Control system

1) Electrical control: including electrical cabinet and a complete set of electrical components, manual BT4 safety explosion-proof type

D installation, heat preservation

1) Piping system: including pipes, valves, sight glasses, fasteners, and gaskets. The contact material part is 304, see the flow chart for details

2) Platform: stainless steel, frame only, stair guardrail not included

3) Vacuum pump frame: material carbon steel

E equipment packaging and transportation

1) Packaging + transportation: pick up by the factory or ship to the export port

F public works

1) Total power supply: the customer is responsible / the buyer shall provide it by himself

2) Circulating cooling water: the customer is responsible / the buyer shall provide it by himself

3) Compressed air/other air source: the customer is responsible/the purchaser shall provide it by himself

4) Supporting utilities: heat transfer oil, ethylene glycol, and vacuum pump oil are the responsibility of the customer/the purchaser shall prepare it by himself

4. Equipment Applications

A food industry

1. Production of monoglycerides

Molecular distillation rectification extraction technology is widely used in the food industry for the separation of mixed fats and oils to obtain food emulsifiers (monoglycerides of fatty acids)> 90% of high purity products. The use of molecular distillation and rectification extraction technology can obtain high purity products with monoglycerides >90%. This method is a commonly used and effective method in the industrial high-purity monoglyceride production method at present, and the monoglyceride can meet the requirements of food grade. Molecular distillation and rectification to extract monoglycerides gradually replaced ordinary monoglycerides with low purity and deep color. The market prospects are considerable. Molecular distillation and rectification to extract monoglycerides can bring huge profits to enterprises.

2. Refining of fish oil

To extract natural products from animals, molecular distillation and rectification extraction techniques, such as refined fish oil, are also widely used. Therefore, molecular distillation is an effective method to separate and purify EPA and DHA.

3. Deacidification of grease

In the process of oil production, the crude oil extracted from the oil contains a certain amount of free fatty acids, which affects the color, flavor and shelf life of the oil. The use of molecular distillation and rectification extraction technology has a good effect on the deacidification of high acid value oils and has broad application prospects.

4. Refining of high-carbon alcohols

High-carbon fatty alcohols refer to straight-chain saturated alcohols with more than twenty carbons, which have a variety of physiological activities. After extraction and purification by molecular distillation, the purity of high-carbon alcohol reaches w (higher alcohol) = 96%, of which w (octacosanol) = 16 7%. Using molecular distillation and rectification extraction technology to refine high-carbon alcohols, the process is simple, the operation is safe and reliable, and the product quality is high.

Application of B in fine chemicals

Molecular distillation extraction technology can be used in the fine chemical industry for the separation of hydrocarbons, crude oil and the like; the purification of surfactants and the preparation of chemical intermediates; the deodorization and decolorization of lanolin and its derivatives; plastic plasticization Refining agents and stabilizers, and refining silicone oils, paraffin oils, and high-grade lubricating oils. In the separation of natural products, many aromatic oils are refined and purified by molecular distillation to obtain high-quality essential oils.

1. Purification of aromatic oil

Molecular distillation rectification extraction technology is an effective method to purify essential oils. It can concentrate a certain main component in aromatic oil, remove odor and colored impurities, and improve its purity. It is carried out under high vacuum and lower temperature, and the heating time of the material is extremely short, which guarantees the quality of essential oils, especially for aromatic oils with high boiling point and heat-sensitive ingredients, which shows its superiority. Different types of effective ingredients and their relative contents can be obtained by adjusting different distillation temperatures and vacuum degrees, and relatively high effective ingredients can be obtained by adjusting suitable distillation temperature and vacuum degrees.

2. Purification of polymer intermediates

Molecular distillation rectification extraction technology can excellently protect the quality of polymer products, improve product purity, simplify the process, and reduce costs.

3. Extraction of lanolin

Lanolin and its derivatives are widely used in cosmetics. Separate the components by molecular distillation extraction technology, and modify different components by physical and chemical methods to obtain polyoxyethylene lanolin, acetyl lanolin, lanolin acid, isopropyl ester and wool polyoxyethylene resin, etc. Lanolin products with excellent performance.

C Other industries

Biology, home textiles, etc.

5. Equipment features:

1). Ordinary distillation is carried out at the boiling point temperature. The molecular distillation extraction equipment can be carried out at any temperature. As long as there is a temperature difference between the hot and cold sides, the separation can be achieved.

2). Ordinary distillation is a reversible process of evaporation and condensation. The liquid phase and the gas phase can form a phase equilibrium state; while in the molecular distillation extraction process of molecular distillation, the molecules escaping from the evaporation surface directly fly to the condensation surface. It does not collide with other molecules, and theoretically there is no possibility of returning to the evaporation surface. Therefore, the molecular distillation process is irreversible.

3). Ordinary distillation has bubbling and boiling phenomena; the molecular distillation extraction process is free evaporation on the surface of the liquid layer without bubbling.

4) The separation factor of ordinary distillation separation ability is related to the ratio of the vapor pressure of the component, and the separation factor of molecular distillation extraction separation ability is related to the ratio of the vapor pressure and molecular weight of the component, and can be obtained from the relative evaporation speed.

Product structure