- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0-80KW

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

100 KG

-

Product Name:

-

beer brewing equipment for micro brewery

-

Standard:

-

CE UL TUV.

-

Material:

-

SUS 304, SUS 316

-

Polish:

-

0.6um

-

Thickness:

-

Inner:4.0mm, Jacket: 2.0mm

-

Pressure:

-

Test: 0.3Mpa

-

Capacity in liters:

-

200L,3000L, 5000L, 1000L, 2000L, 3000L, 4000L,5000L.

-

Capacity in BBL:

-

3BBL, 5BBL, 7BBL, 10BBL, 20BBL, 30BBL, 40BBL.

-

Insulation:

-

100mm Polyurethane

-

Valves:

-

carbonation stone, spray ball, sample, pressure, drain, release etc.

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Cassman

-

Voltage:

-

Adjustable

-

Power:

-

0-80KW

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

100 KG

-

Product Name:

-

beer brewing equipment for micro brewery

-

Standard:

-

CE UL TUV.

-

Material:

-

SUS 304, SUS 316

-

Polish:

-

0.6um

-

Thickness:

-

Inner:4.0mm, Jacket: 2.0mm

-

Pressure:

-

Test: 0.3Mpa

-

Capacity in liters:

-

200L,3000L, 5000L, 1000L, 2000L, 3000L, 4000L,5000L.

-

Capacity in BBL:

-

3BBL, 5BBL, 7BBL, 10BBL, 20BBL, 30BBL, 40BBL.

-

Insulation:

-

100mm Polyurethane

-

Valves:

-

carbonation stone, spray ball, sample, pressure, drain, release etc.

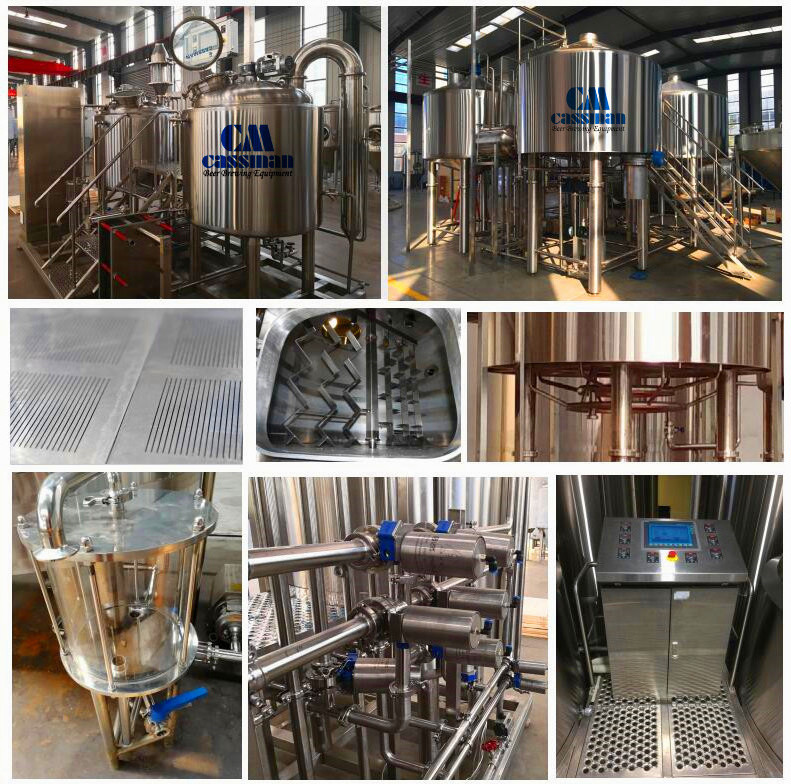

second hand beer making machine home craft beer brewery equipment used germany

Turnkey Brewery Euipment

1----Mill System

Capacity: 100kg/h, 300kg/h, 500kg/h, 800kg/h, 1000kg/h.

Description: CE or UL listed Motor, Double roller, distance adjustable, stainelss steel 304 material.

Optional: Flexible Auger.

2----Brew House System

-Two-Four vessles or combined system.

-Capacity 100L-5000L, 1bbl-40bbl.

- Steam heated, electrical heated or natural gas

-Mash tun with mixer, steam jacket, VFD motor, insulated 80mm. Stainelsss steel 304.

-Lauter tun with rake system, milled false bottom, sparging spray ring, VFD motor, insulated 80mm.

-Boiling kettle with steam jacket, inner heated option, insulated 80mm. Stainelsss steel 304.

-Whirlpool with Tangential whirlpool inlet . insulated 80mm. Stainelsss steel 304.

-Insulated HLT and CLT with the pipelines and pumps

- External grant, hops back, heat exchanger. Wort oxygenation system, working platform.

-All the necessary pipelines and pumps.

| 50L | 100L | 200L | 300L | 400L | 500L | 1000L | 2000L | 3000L | 5000L |

| 60/72 | 60/72 | 60/72 | 60/72 | 60/72 | 60/72 | 60/72 | 60/72 | 60/72 | 60/72 |

3----Fermenter&BBT System

-Capacity: 100L-30000L, 1bbl-100bbl, + 25 % Head space

-Interior shell thickness 3-6 mm, Exterior shell=2mm

-100% TIG welding with pure argon gas shield

-Interior finish: pickled and passivated, external polished, 80mm insulated

- Test pressure 3 bar, working pressure 1.5 bar

-Glycol zones (Both on side and concial/bottom)

-60°conical bottom for Fermener, Shadow less side man way

-Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

-Mechanical relief valve 3 bar on CIP arm with pressure gauge

-Adjustable tank leveling pads

3----Cooling System

Description: Air type chiller + Ice water tank or Glycol tank

Capacity: 3HP, 5HP, 7HP, 10HP, 15HP, 20HP, 30HP+ 500L-20000L tank

Brand: Copeland, SANYO.

4----Control System

-PID or PLC system

-SIEMENS program S7-200, Siemens touch screen.

-Penumatic valves for optional

5----Canning line, Kegging line

-Double station Kegging line.

-Small capacity Canning line.

Reference and Customers Visiting

Packge and Shipping

Cassman Factory

Contact Us