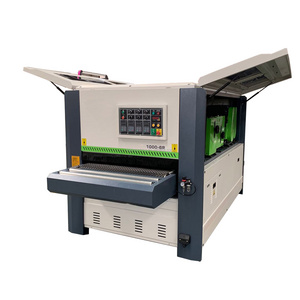

- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

/

-

Weight (KG):

-

5500 KG

-

Name:

-

Wood Brush Machine

-

Max Working Width:

-

1100mm

-

Working Thickness:

-

100mm

-

Conveyor Speed:

-

0-10m/min Frequency conversion speed

-

Vacuuming Mouth:

-

17*100mm

-

Suction Air:

-

17*635m3/h

-

Total Power:

-

24.2kw

-

Weight:

-

5500kg

-

Overall Dimensions:

-

5950*1950*2275mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HICAS

-

Machine Type:

-

Brush Sanding Machine

-

Core Components:

-

/

-

Weight (KG):

-

5500 KG

-

Name:

-

Wood Brush Machine

-

Max Working Width:

-

1100mm

-

Working Thickness:

-

100mm

-

Conveyor Speed:

-

0-10m/min Frequency conversion speed

-

Vacuuming Mouth:

-

17*100mm

-

Suction Air:

-

17*635m3/h

-

Total Power:

-

24.2kw

-

Weight:

-

5500kg

-

Overall Dimensions:

-

5950*1950*2275mm

Product Description

|

Name

|

Sanding Machine

|

|

Model

|

FK-G9-1300

|

|

Working thickness

|

100mm

|

|

Adjustable brush speed

|

80-450rpm(can adjust)

|

|

Screw roller speed

|

80-550 rpm(can adjust)

|

|

Conveyor speed

|

0-10m/min(can adjust)

|

|

Each group of the lifting power

|

8*0.25kw

|

|

Integral lifting power

|

2kw

|

|

Disc brush motor power

|

2*0.55kw

|

|

Disc brush motor power

|

2*1.5kw

|

|

Screw roller motor power

|

5*2.2kw

|

|

Horizontal roller motor power

|

2*1.1kw

|

|

Conveyor motor power

|

2.2kw

|

|

Swing motor power

|

8*0.2kw

|

|

Total power

|

24.2kw

|

|

Screw roller number

|

1 set

|

|

Screw roller diameter

|

420mm

|

|

Brush plate number in each group

|

3*3 set

|

|

Brush tray diameter

|

180mm

|

|

Horizontal roller number

|

8 sets

|

|

Horizontal roller diameter

|

350mm

|

|

Vacuuming mouth

|

17*100mm

|

|

The wind speed

|

22-30m/s

|

|

Suction air

|

17*635m3/h

|

|

The weight

|

6200kg

|

|

The overall dimensions

|

5950*2150*2275mm

|

|

Consumtion power

|

About 8-12kw/h

|

Detailed Images

Japan SEND Motor

Germany Siemens Electric appliance

China

Liteon Frequency converter

Germany Continental Belt

China ZhouYi Reducer

China HIWIN Guide bearing

Work Steps

Advantages:

1.

Each sanding unit can be adjusted independently, and can be fine-tuned according to the product process to ensure the maximum combination of abrasive and workpiece, which can significantly improve the grinding effect. Strengthen the independent lifting mechanism to make the grinding process more stable.

2. Each sanding unit can independently adjust the speed, effectively improve the quality of grinding, prevent damage to the shape and paint leakage.

3. Each sanding unit cooperates with swing system to make the grinding range wider and more uniform, and effectively avoid scratches caused by long grinding.

4. Each sanding unit is equipped with a human-designed drawing system, which makes it easier to replace consumables.

5. Each group of sanding units with thickness display function, the operation is more intuitive , convenient (Note:This model can choose memory function).

6. Large diameter sanding roller structure , matched with high quality sand paper , mexico sisal, softer and flexible, and it is easier to sand the complex design products.

7. Each sanding unit is removable .This structure is more portable to replace the sanding paper or sanding part and it is easier to sand the complex design products and it is convenient for maintenance.

2. Each sanding unit can independently adjust the speed, effectively improve the quality of grinding, prevent damage to the shape and paint leakage.

3. Each sanding unit cooperates with swing system to make the grinding range wider and more uniform, and effectively avoid scratches caused by long grinding.

4. Each sanding unit is equipped with a human-designed drawing system, which makes it easier to replace consumables.

5. Each group of sanding units with thickness display function, the operation is more intuitive , convenient (Note:This model can choose memory function).

6. Large diameter sanding roller structure , matched with high quality sand paper , mexico sisal, softer and flexible, and it is easier to sand the complex design products.

7. Each sanding unit is removable .This structure is more portable to replace the sanding paper or sanding part and it is easier to sand the complex design products and it is convenient for maintenance.

8. Brush disc adopts the high speed disassembly structure , effectively shortens the replacement time of the sand paper, which is faster and more efficient than the traditional structure

Final Product

Related Products

Hot Searches