- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Bathroom

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Blosam

-

Model Number:

-

XPS TILE BACKER BOARD

-

Type:

-

XPS TILE BACKER BOARD

-

Product name:

-

Tile Backer Board 3'x5'x1/2"

-

Size:

-

3ft x 5ft

-

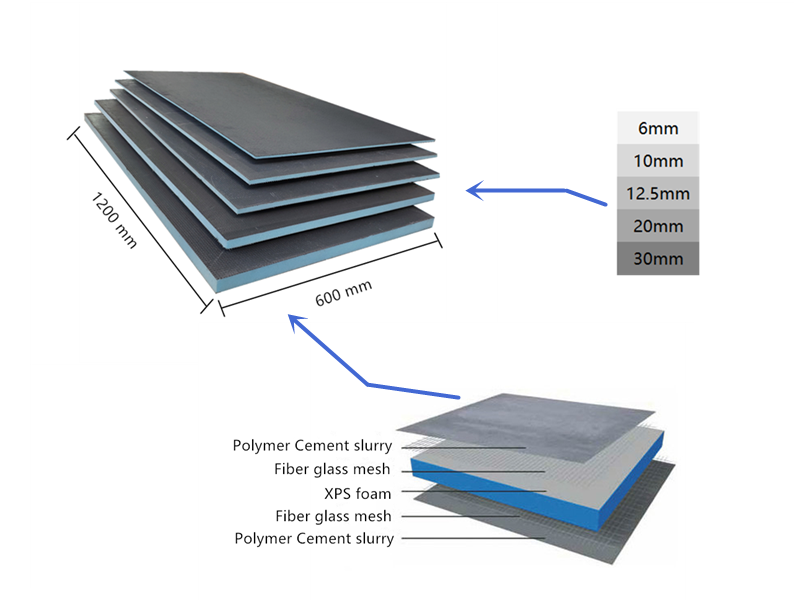

Thickness:

-

1/2inch

-

Keyword:

-

Xps Foam Sheet Insulation

-

Material:

-

Extruded Polystyrene Foam+Glass fiber mesh+polymer coating

-

Feature1:

-

100% waterproof, Light-weight, easy to handle and cut

-

Feature2:

-

High-rigidity & durability

-

Feature3:

-

Close bond to any tiling walls or floors

-

Feature4:

-

Available at various thickness and sizes

Quick Details

-

Warranty:

-

5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

Others

-

Application:

-

Bathroom

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Blosam

-

Model Number:

-

XPS TILE BACKER BOARD

-

Type:

-

XPS TILE BACKER BOARD

-

Product name:

-

Tile Backer Board 3'x5'x1/2"

-

Size:

-

3ft x 5ft

-

Thickness:

-

1/2inch

-

Keyword:

-

Xps Foam Sheet Insulation

-

Material:

-

Extruded Polystyrene Foam+Glass fiber mesh+polymer coating

-

Feature1:

-

100% waterproof, Light-weight, easy to handle and cut

-

Feature2:

-

High-rigidity & durability

-

Feature3:

-

Close bond to any tiling walls or floors

-

Feature4:

-

Available at various thickness and sizes

Product Description

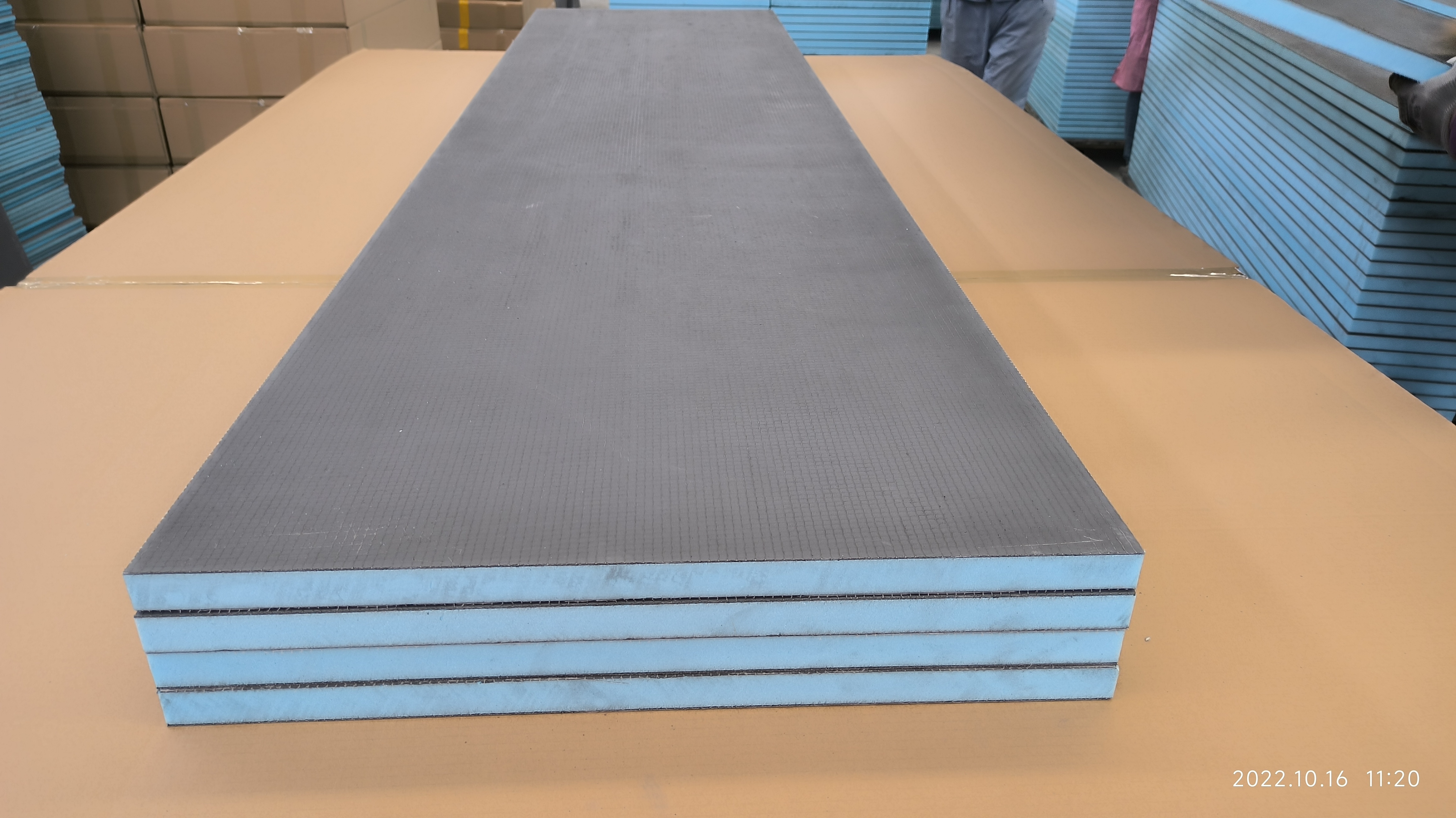

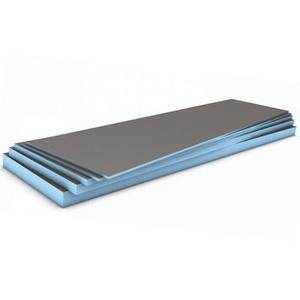

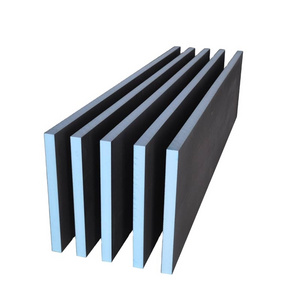

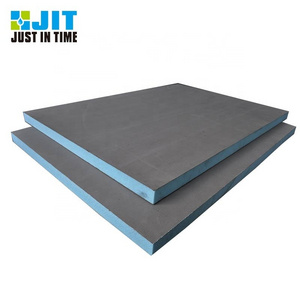

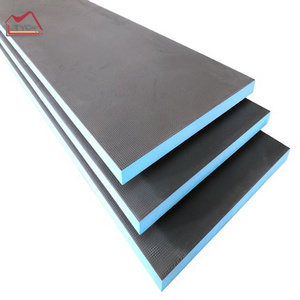

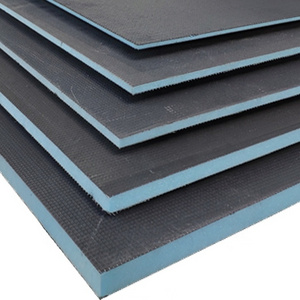

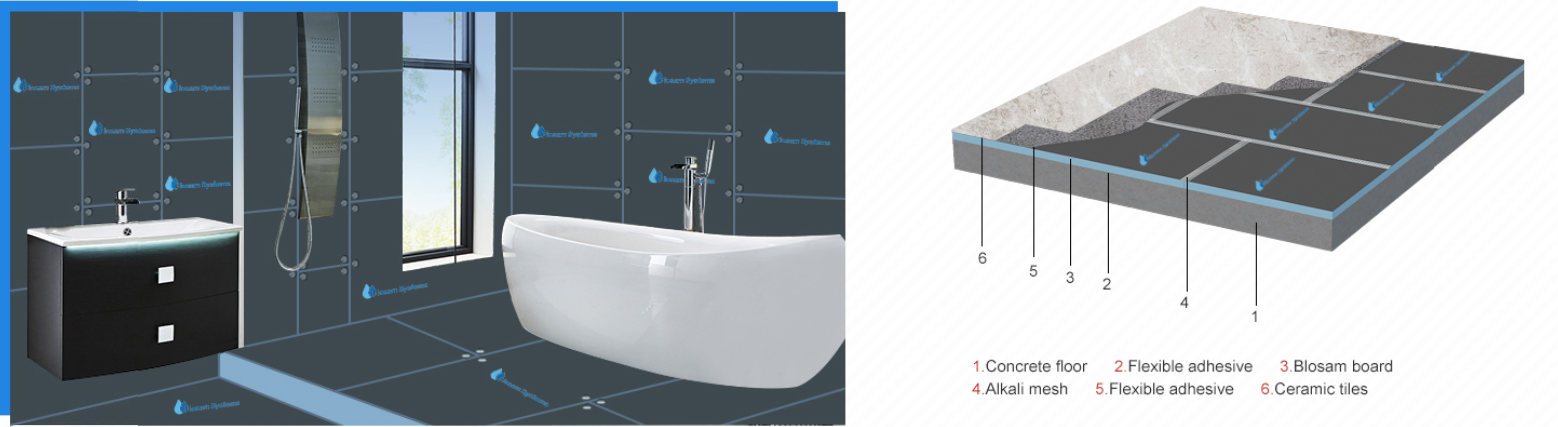

Tile Backer boards are made of high-performance waterproof extruded polystyrene.it has a polymer coating on either side comprising a glass fiber mesh embedded in a polymer cement mortar. The boards have straight edges. The color of the surface is grey and the core material is light blue or white.

Feature

1. 100% waterproof, made of HCFC-FREE XPS foam

2. High-rigidity and durability

3. Close bond to any tiling walls or floors

4. Available at various thickness and sizes

5. Compatibility to multiple substructures

6. Vapor retardant against mildew

7. Light-weight, easy to handle and cut with utility knife

3. Close bond to any tiling walls or floors

4. Available at various thickness and sizes

5. Compatibility to multiple substructures

6. Vapor retardant against mildew

7. Light-weight, easy to handle and cut with utility knife

XPS tile backer board is a kind of basic construction board. It can be cut to different

shape and there are many application cases. Not only the wall panels, but also the shower tray, shower niches, shower curb, shower bench, pipe coverings, toilet board and etc.

Steps made of tile backer boards

Countertop made of tile backer board

Bench/ seat made of tile backer board

Wall Panels, Shower Niche and Pipe Coverings made of xps tile backer boards.

NOT ONLY FOR THE RESIDENTIAL USE

BUT ALSO FOR COMMERCIAL USE.

xps tile backer board is very suitable for metal frame projects:

Related Products

FAQ

Underfloor Heating Insulation Cement Coated Tile Backer Board

1. Could you develop some certain product with tile backer board and shower tray for us?

Answer: Yes, we have strong R&D Capability, we are welcome you to discuss the new idea with us.

2. Do you have any product certification for your tile backer board and shower tray ?

Answer: Our Shower system have certain CE Certification, also our certain product tested in USA with good performance in TCNA and

IAPMO. If you need the SINTEF OR SONAP, we could apply the certification together.

3. How is your production time ?

Answer: Normally it take 15-25 days and it vary according to the product quantity.

4. How many countries and areas have your product shipped?

Answer: We have shopped our shower system to United States, United Kingdom, Ireland, Canada, Russia, Netherland, Nigeria, Sweden,

Republic of Lithuania etc.

5. Do you provide OEM/ODM service?

Answer: Yes, we could produce the product with private labeled.

ATTENTION

Fixing

Choose a way to fix our boards according to the substrate to be fixed to. Normally, using modified tile adhesive for solid

concrete wall/floor and strengthened by mechanical fixings when necessary while only using mechanical fixings for wood and steel

frames.

Reinforcement

1. Dry areas: reinforce all joints between boards, floors and walls by 5cm or 10cm wide self-adhesive tape.

2. Wet areas: reinforce by suitable waterproof tape.

Waterproof strengthen

1. Strengthening all joints between boards, floors, walls and mechanical fixings placements by suitable waterproof tape.

2. Strengthening joints between walls, outside corners and inside corners by special corners.

3. Sealing pipe holes with special waterproof tape.

4. Strengthening once again by waterproof glue, liquid tanking membrane, tanking membrane paint, etc. when necessary.

Coating of panels

Should always be covered by ceramic tiles, mosaics or other equivalent non-fireproof materials after installation.

1. Could you develop some certain product with tile backer board and shower tray for us?

Answer: Yes, we have strong R&D Capability, we are welcome you to discuss the new idea with us.

2. Do you have any product certification for your tile backer board and shower tray ?

Answer: Our Shower system have certain CE Certification, also our certain product tested in USA with good performance in TCNA and

IAPMO. If you need the SINTEF OR SONAP, we could apply the certification together.

3. How is your production time ?

Answer: Normally it take 15-25 days and it vary according to the product quantity.

4. How many countries and areas have your product shipped?

Answer: We have shopped our shower system to United States, United Kingdom, Ireland, Canada, Russia, Netherland, Nigeria, Sweden,

Republic of Lithuania etc.

5. Do you provide OEM/ODM service?

Answer: Yes, we could produce the product with private labeled.

ATTENTION

Fixing

Choose a way to fix our boards according to the substrate to be fixed to. Normally, using modified tile adhesive for solid

concrete wall/floor and strengthened by mechanical fixings when necessary while only using mechanical fixings for wood and steel

frames.

Reinforcement

1. Dry areas: reinforce all joints between boards, floors and walls by 5cm or 10cm wide self-adhesive tape.

2. Wet areas: reinforce by suitable waterproof tape.

Waterproof strengthen

1. Strengthening all joints between boards, floors, walls and mechanical fixings placements by suitable waterproof tape.

2. Strengthening joints between walls, outside corners and inside corners by special corners.

3. Sealing pipe holes with special waterproof tape.

4. Strengthening once again by waterproof glue, liquid tanking membrane, tanking membrane paint, etc. when necessary.

Coating of panels

Should always be covered by ceramic tiles, mosaics or other equivalent non-fireproof materials after installation.

Contact US

Richard Chan

Wechat/Whatsapp/Mobile:+86 18666409098

www.sanyibuilding.cn ; www.tilebacker.cn

http://sunway-china.en.alibaba.com

http://facebook.com/backerboard

https://twitter.com/tilebackerboard

We do OEM as well. Welcome to make an enquiry and we will give you quick response in 12 hours!

www.sanyibuilding.cn ; www.tilebacker.cn

http://sunway-china.en.alibaba.com

http://facebook.com/backerboard

https://twitter.com/tilebackerboard

We do OEM as well. Welcome to make an enquiry and we will give you quick response in 12 hours!

Hot Searches