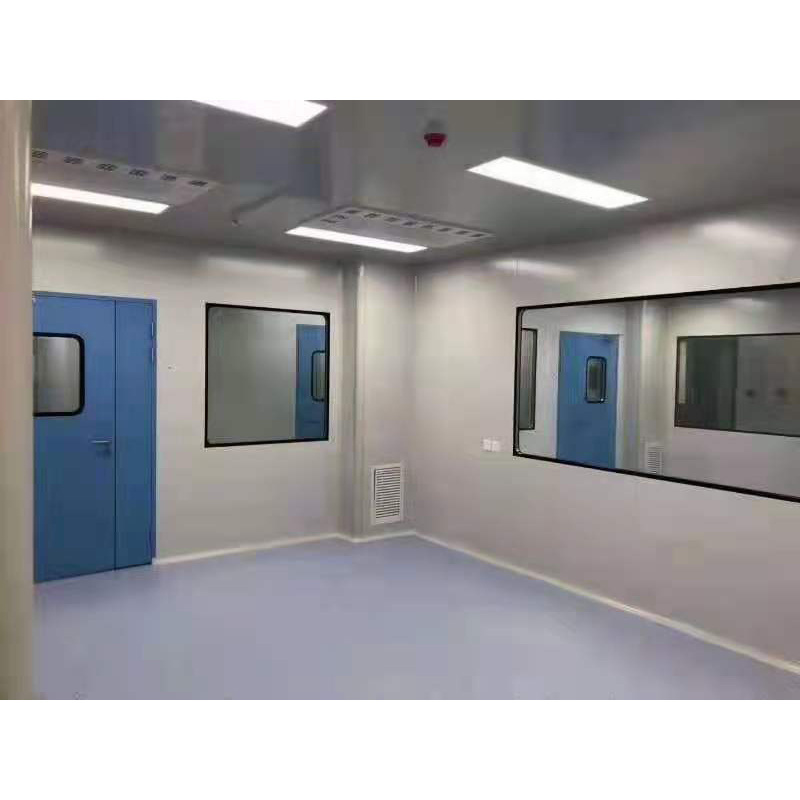

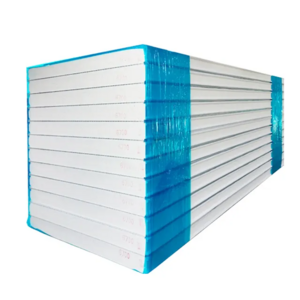

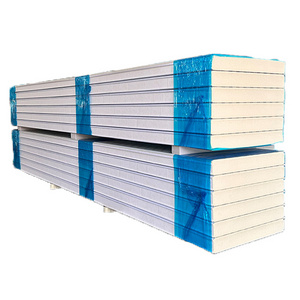

1. Mgo sandwich panel: A class fire rating , Good weight capacity , can bearing 150-250kg/m2. More safety.

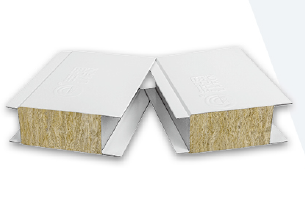

2. Rock wool sandwich panel : Class A , good heat preservation and sound insulation , efficient affordable.

3. Silicon rock panel: water proof , class A , good quality with lower price.

Can choose the panel exactly according to what you need.